Fixing manner of elastic piece and inserting piece of relay

A fixed method and relay technology, applied to relay parts, relays, circuits, etc., can solve the problems of high scrap rate of parts, difficulty in guaranteeing parts size, and low degree of mechanical automation production, so as to achieve high degree of mechanical automation and save molds The effect of high cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] see Figure 1-Figure 7 , The shrapnel and the insertion piece of the relay include the shrapnel 1 and the insertion piece 2, which are formed by continuous stamping and fixedly connected.

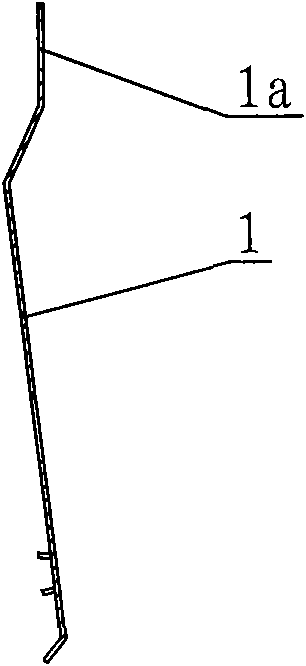

[0030] see figure 1 , figure 2 , The shrapnel 1 is a long sheet with a zigzag cross-section, one end of which is provided with a positioning hole and a joint, and the other end is provided with two small holes 1a which are fixedly connected with the insertion piece 2 .

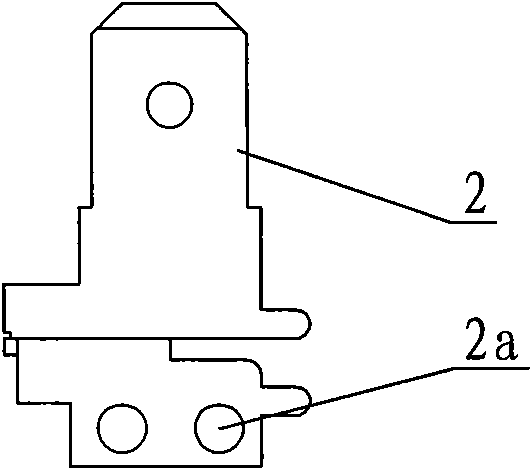

[0031] see image 3 , Figure 4 , the insert piece 2 is a strip with a zigzag-shaped cross section, and its thickness is thicker than that of the shrapnel 1. One end is a plug with a positioning hole, and the other end is provided with two upwardly convex protrusions corresponding to the two small holes 1a of the shrapnel 1. Edge 2a.

[0032] see Figure 5-Figure 7 , the fixing method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com