Dual-seal spherical compensating joint

A spherical compensation and double-sealing technology, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of low safety and reliability, poor sealing effect, etc., and achieve good sealing effect and simple structure , High safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

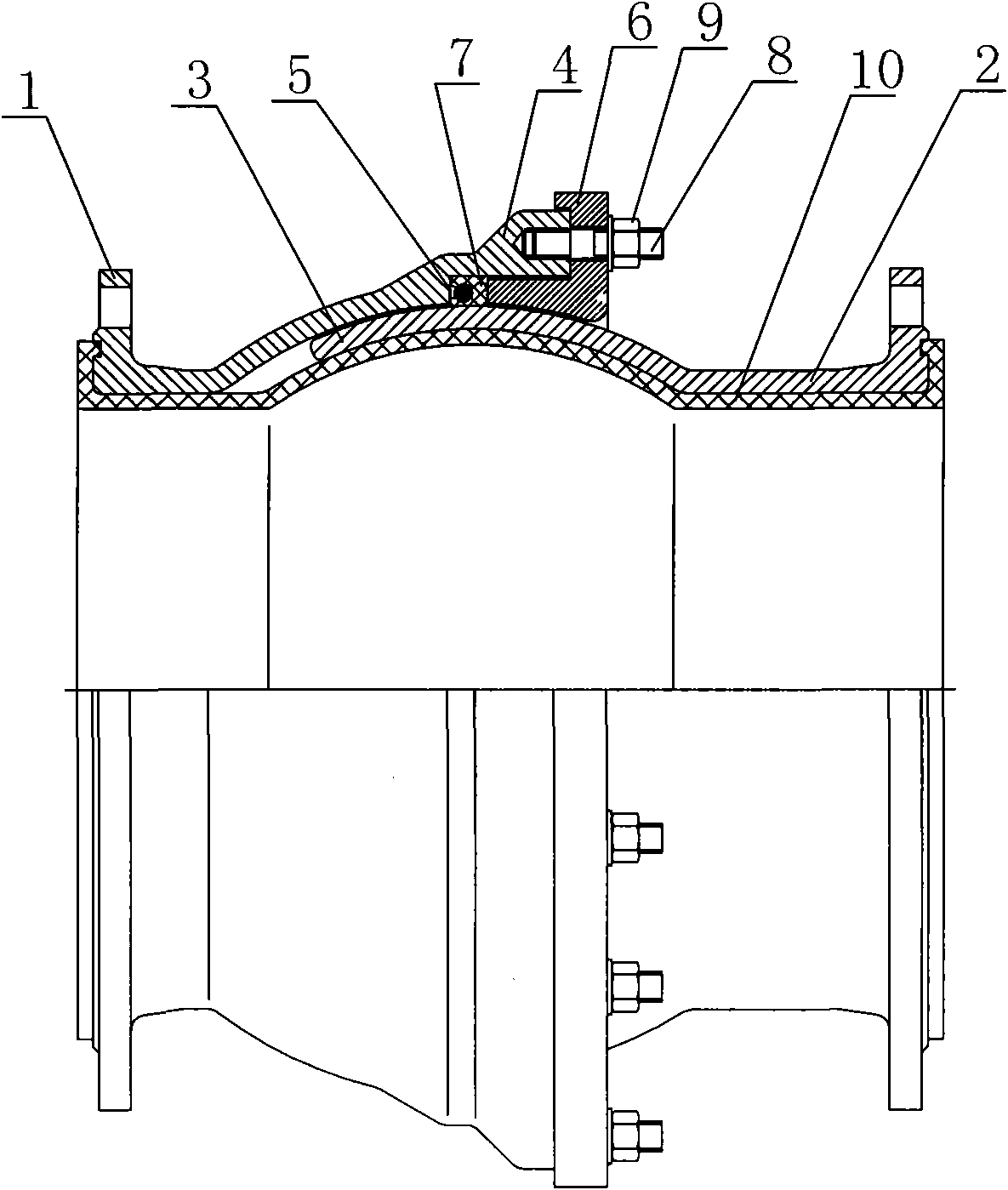

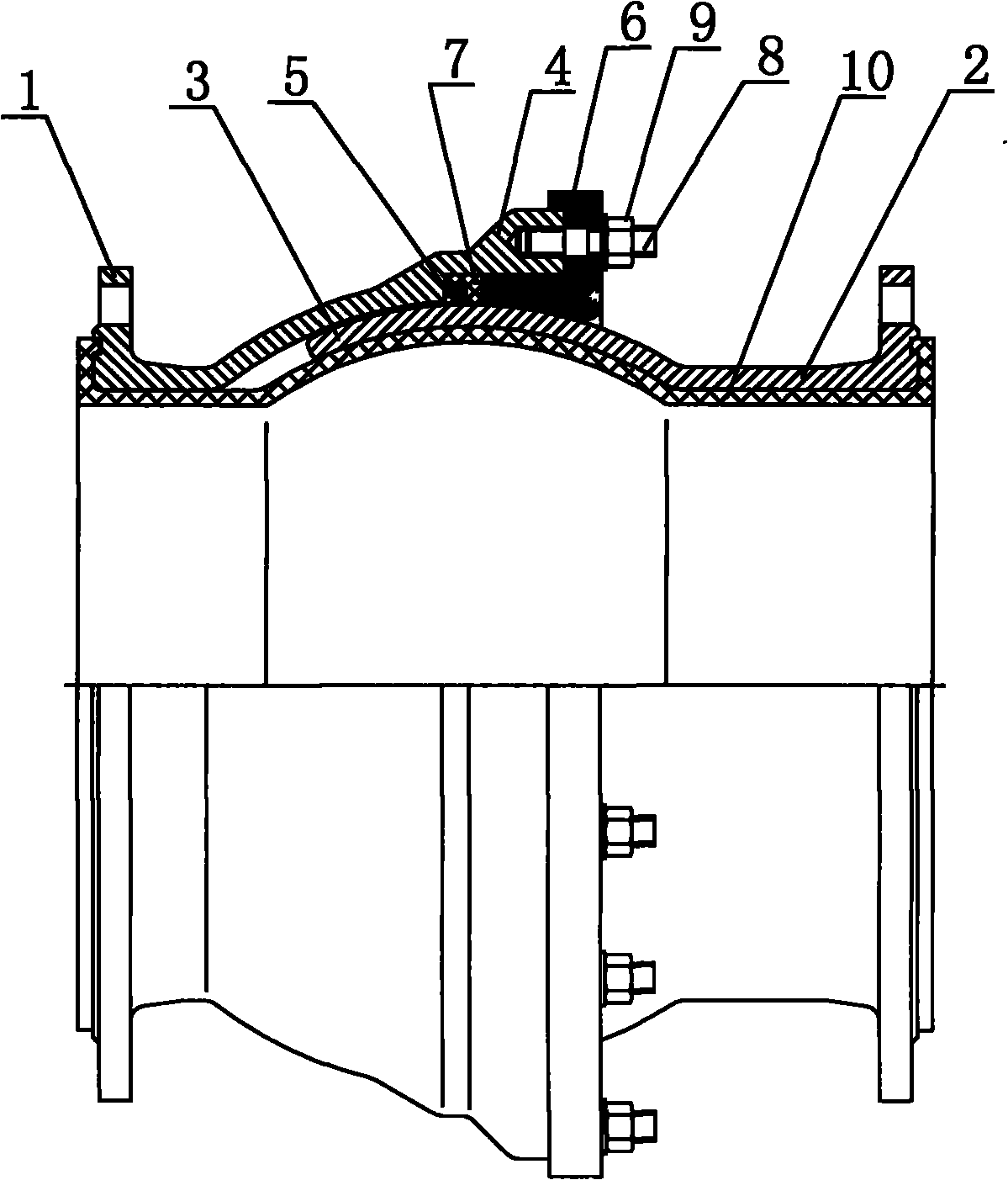

[0013] Please refer to figure 1 as shown, figure 1 It is a schematic diagram of the structure of the double-sealed spherical compensation joint of the present invention. In this embodiment, a double-sealed spherical compensation joint includes a body 2 and a spherical shell 1. A section of the inner cavity of the spherical shell 1 is spherical, and is located on the body 2. Correspondingly, there is a body spherical surface 3 that matches with the spherical shell 1. The body spherical surface 3 is set in the inner cavity of the spherical shell 1, and one end of the spherical shell 1 extends outwards with a joint 4, and the joint 4 and the ball The inner wall of the shell 1 forms a spherical shell step 5, and the end surface of the joint part 4 is connected to the gland 6 through the connecting bolt 8 and the connecting nut 9. The inner cavity shape of the gland 6 matches the inner cavity of the spherical shell 1 to form a spherical inner cavity. cavity, and a U-shaped sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com