Light wall plate

A lightweight wallboard and core board technology, applied in building components, buildings, building structures, etc., can solve the problems of increased construction cost, wallboard damage, low strength, etc., to reduce project costs, ensure product quality, Easy to disassemble and move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below with reference to the accompanying drawings and embodiments.

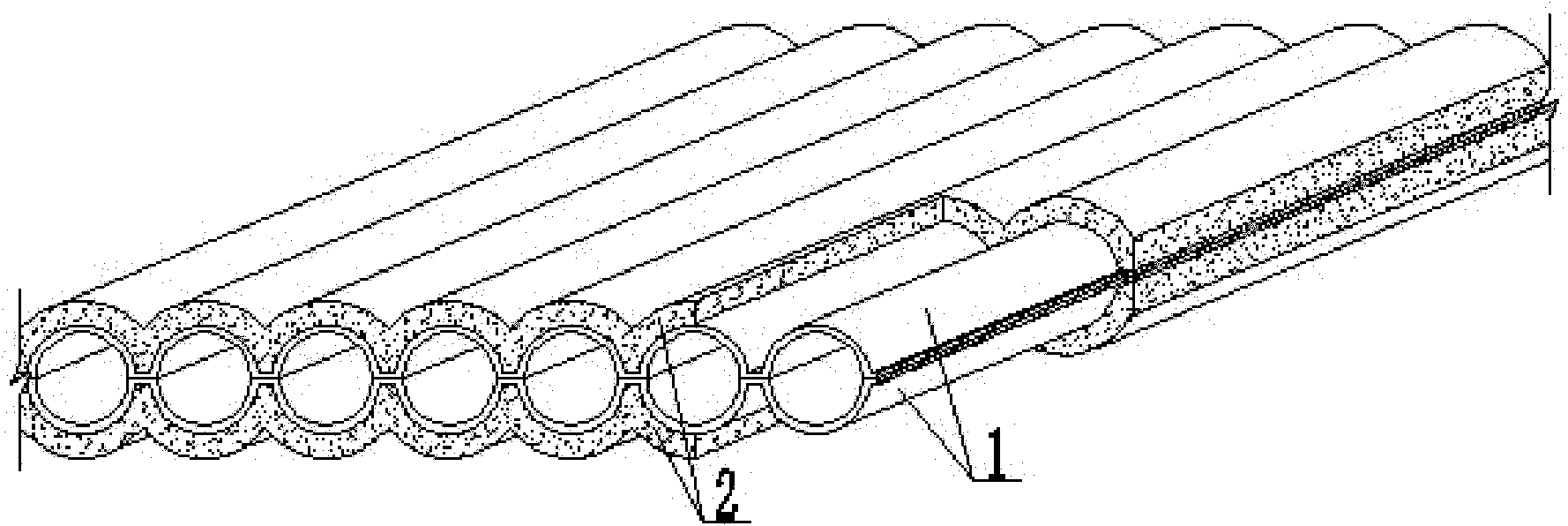

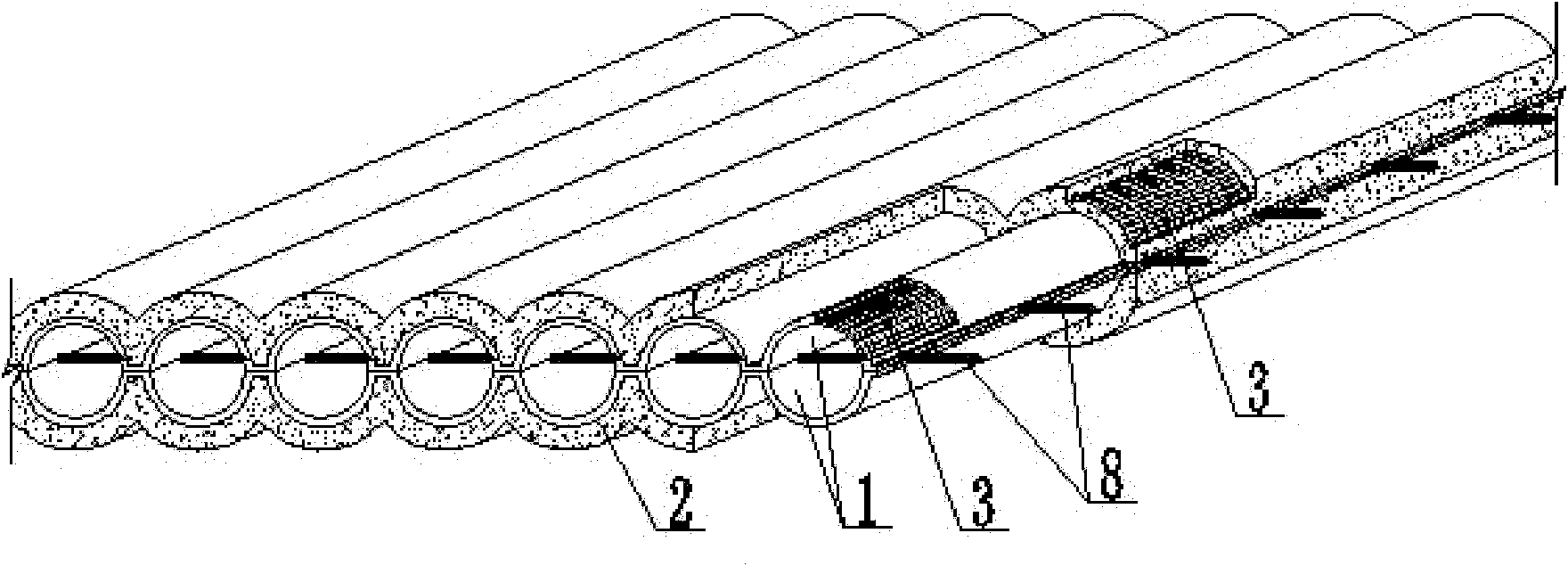

[0097] As shown in the accompanying drawings, the present invention includes a core board part 1 , which is characterized in that two core board parts 1 are relatively fastened, and an external plastering mortar 2 is applied to the outside of the core board part 1 . In each of the drawings, 1 is a core board member. In the following drawings, the same reference numerals are used, and the descriptions thereof are the same. like figure 1 As shown, a lightweight wallboard includes a core board part 1, which is characterized in that two core board parts 1 are relatively fastened, and the core board part 1 is coated with an external plastering mortar 2.

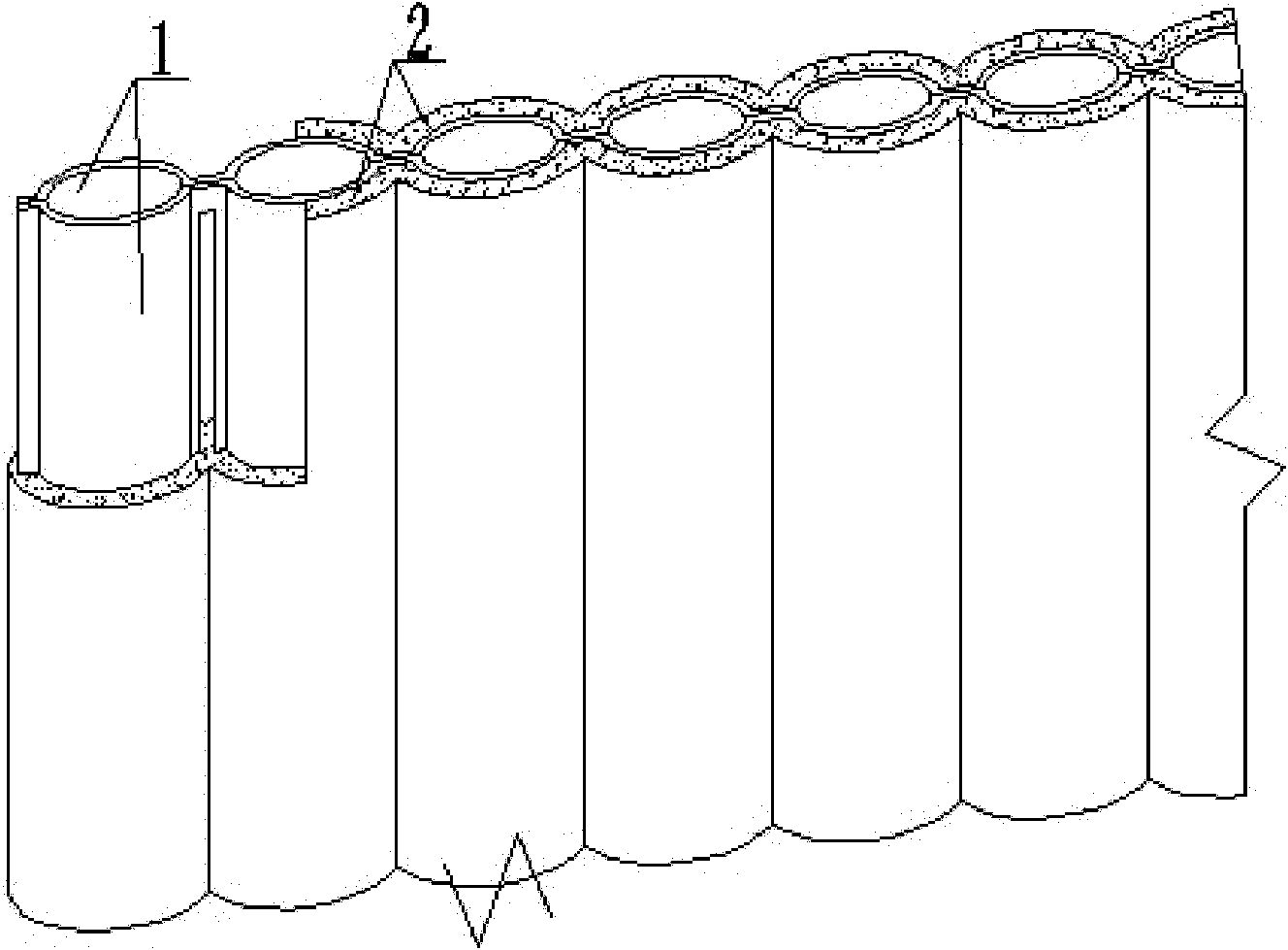

[0098] The feature of the present invention is that the external plastering mortar 2 runs through the seam. like figure 2 As shown, the described external plastering mortar 2 penetrates through the seam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com