Building gas explosion inclined wall structure

A wall structure and gas explosion technology, which is applied in building components, building structures, buildings, etc., can solve the problems of steel-concrete partition walls, such as heavy weight, equipment bump damage, and high humidity in the space, so as to achieve less space occupation and environmental pollution. The effect of reducing and reducing the structural load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with accompanying drawing and construction example the present invention is described further:

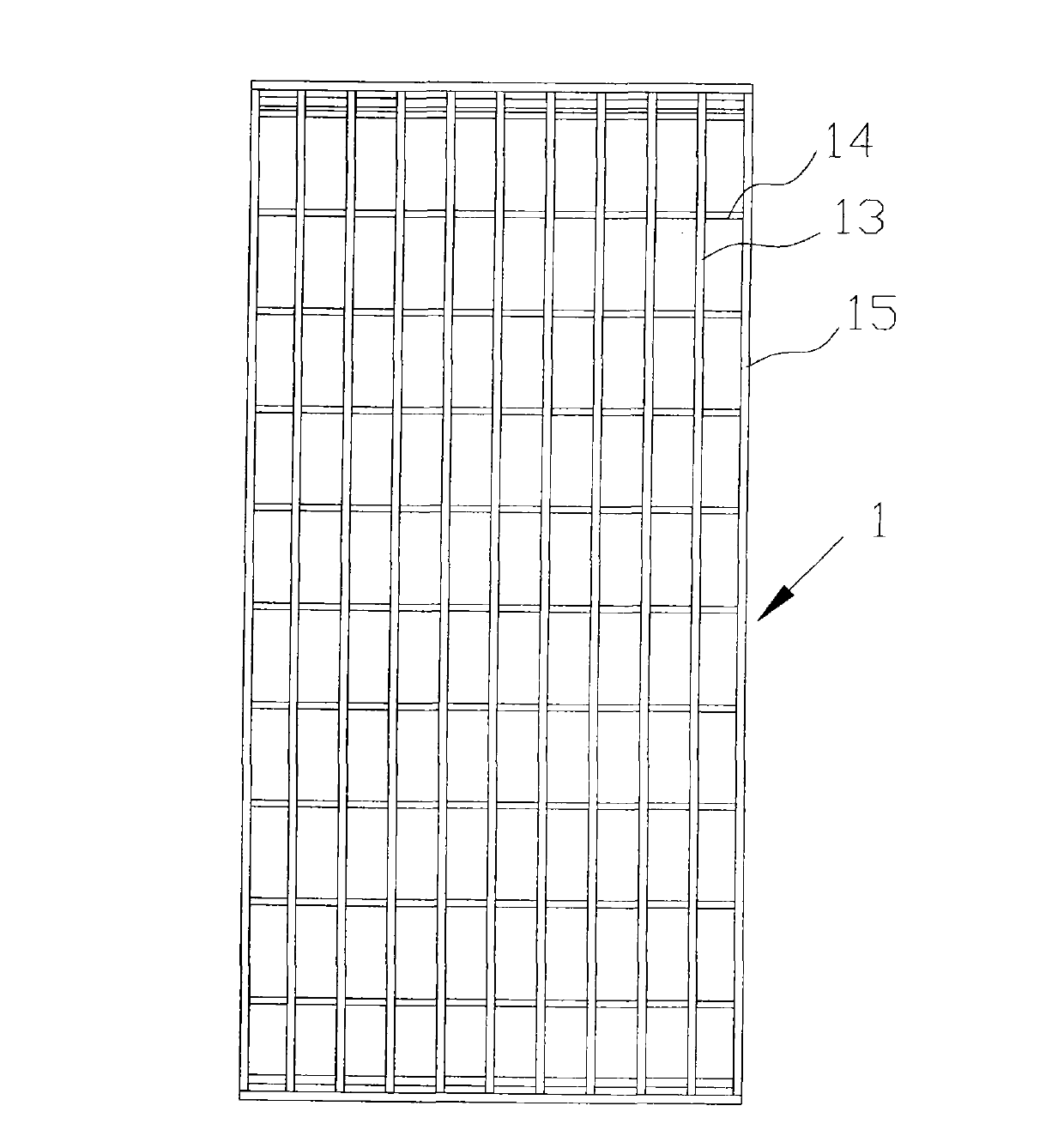

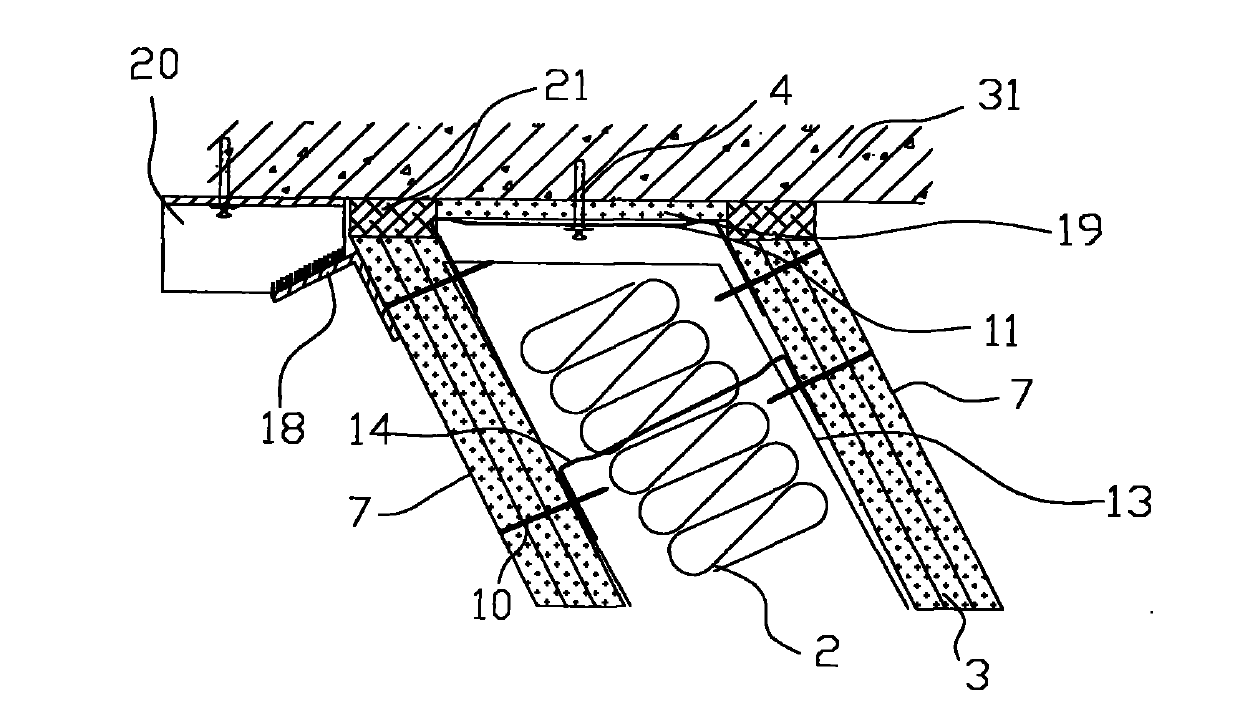

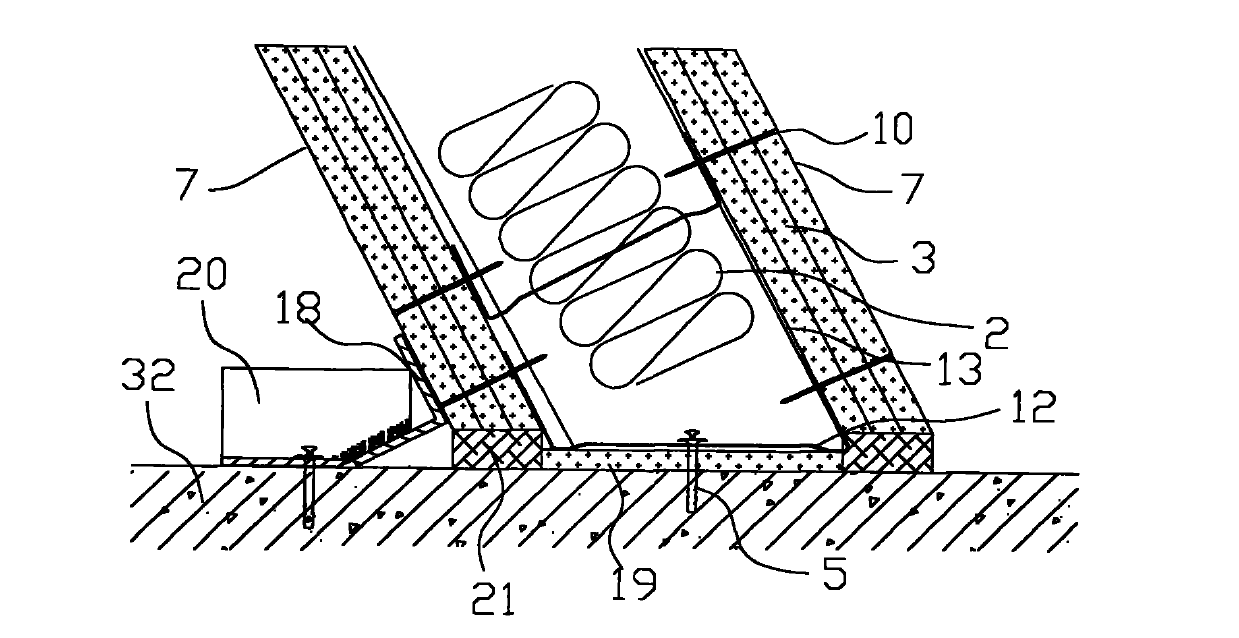

[0016] Such as figure 1 , 2 , 3, the present invention includes: a light steel keel frame 1, the light steel keel frame 1 is arranged between the top structure and the bottom structure of the building with an inclination of 30 degrees, rock wool 2 is filled in the gap of the frame 1, and the frame The two sides of 1 are fitted with three layers of gypsum boards 3 . In the present invention, the skeleton 1 includes a C-shaped sky keel 11, a C-shaped ground keel 12, a C-shaped vertical keel 13 and a U-shaped cross-bracing keel 14; the C-shaped sky keel 11 is installed on the top structure of the building through fasteners 4 The C-shaped ground keel 12 is installed on the bottom structure of the building through the fastener 5, the C-shaped vertical keel 13 is installed between the C-shaped sky keel 11 and the ground keel 12, and the U-shaped horizontal bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com