Anode for improving electroplating uniformity

A uniformity and anode technology, applied in the field of anodes to improve the uniformity of electroplating, can solve the problems of lowering the quality of PCB boards, poor electroplating uniformity of PCB boards, etc., and achieve the effects of improving uniformity, excellent electrical conductivity and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

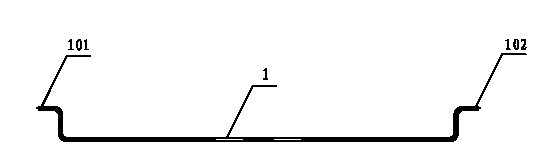

[0030] Such as figure 2 As shown, an anode used to improve the uniformity of electroplating is provided with an access point 101 and 102 connected to the positive pole of the power supply at both ends of the sunken anode rod 1, and at the same time, in the middle of the sunken anode It also includes an access point 103 connected to the positive pole of the power supply. The direct distance between the access point 101 and the access point 103 is equal to the distance between the access point 102 and the access point 103, which is 1.7 meters. This makes the potential of the entire submerged anode rod basically at the same level, the potential difference is small, and the voltage from the anode to the cathode is basically equal, thereby improving the uniformity of electroplating.

[0031] Preferably, the anode is a titanium-clad copper anode. That is, the titanium layer is laminated on the copper surface (substrate), so that it has both the excellent electrical conductivity of...

Embodiment 2

[0033] Such as image 3 As shown, an anode used to improve the uniformity of electroplating has an access point 101 and 102 connected to the positive pole of the power supply at both ends of the anode, and at the same time, there are two connection points connected to the positive pole of the power supply in the middle of the anode. The access points are 103, 104, and 105 respectively, and the distance between adjacent access points is equal, which is 1.5 meters. This makes the potential of the entire submerged anode rod basically at the same level, the potential difference is small, and the voltage from the anode to the cathode is basically equal, thereby improving the uniformity of electroplating.

[0034] Preferably, the anode is a titanium-clad copper anode. That is, the titanium layer is laminated on the copper surface (substrate), so that it has both the excellent electrical conductivity of copper and the excellent corrosion resistance of the outer titanium layer, which...

Embodiment 3

[0036] Such as Figure 5 As shown, a submerged anode rod used to improve the uniformity of electroplating has an access point 101, 102 connected to the positive pole 501 of the rectifier 5 at both ends of the anode rod, and at the same time, there is also an access point in the middle of the anode It includes two access points connected to the positive pole of the rectifier, which are respectively 103 and 104, and the distance between adjacent access points is equal, which is 1.5 meters. When electroplating the PCB board, two submerged anode rods are arranged on both sides of the electroplating tank 3, parallel to each other; the PCB board is located in the center of the electroplating tank 3, parallel to the submerged anode rod, and the PCB board and the The cathode 502 of the machine is electrically connected; at this time, the potentials of A point 11, B point 12, C point 13, D point 14, and E point 15 of the submerged anode rod are basically at the same level as the potent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com