Electrochemical method for predicting electroplating uniformity of electroplating liquid, method for screening electroplating liquid and application

An electroplating solution and electrochemical technology, applied in the direction of material electrochemical variables, electrolytic components, electrolytic process, etc., can solve the problems of limited application of electrochemical methods and achieve good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare two kinds of cyanide-free gold plating solutions A containing different additives (the composition includes: sodium gold sulfite with a gold content of 12g / L, ethylenediamine 10g / L, sodium sulfite 60g / L, sodium ethylenediaminetetraacetate 10g / L, Sodium arsenite 10mg / L, the rest is water, pH8.0) and cyanide-free gold plating solution B (composition includes: gold sodium sulfite with a gold content of 12g / L, ethylenediamine 10g / L, sodium sulfite 60g / L, Sodium edetate 10g / L, thiourea derivative 5mg / L, the rest is water, pH 8.0).

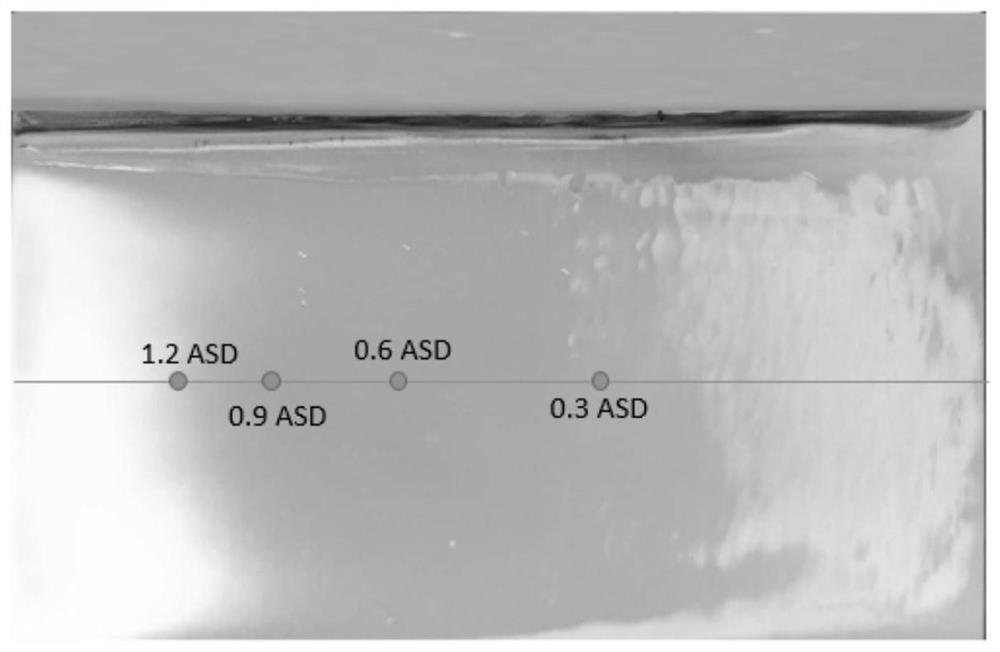

[0049] Inject cyanide-free gold-plating solution A or cyanide-free gold-plating solution B into the electroplating pool, then apply voltage, the initial potential is 0V, the rate of voltage change is 5mV / s, and the termination potential is-0.8V, respectively measure the cyanide-free gold-plating solution A, The electroplating current intensity of cyanide-free gold plating solution B, and drawing, such as figure 1 shown. The electroplati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com