Reel-type submarine pipeline laying workboat and working method thereof

A technology for submarine pipelines and workboats, applied in the direction of pipe-laying ships, etc., can solve problems such as decreased stability, inability to install large-diameter reels, and reduced ability to resist wind and waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

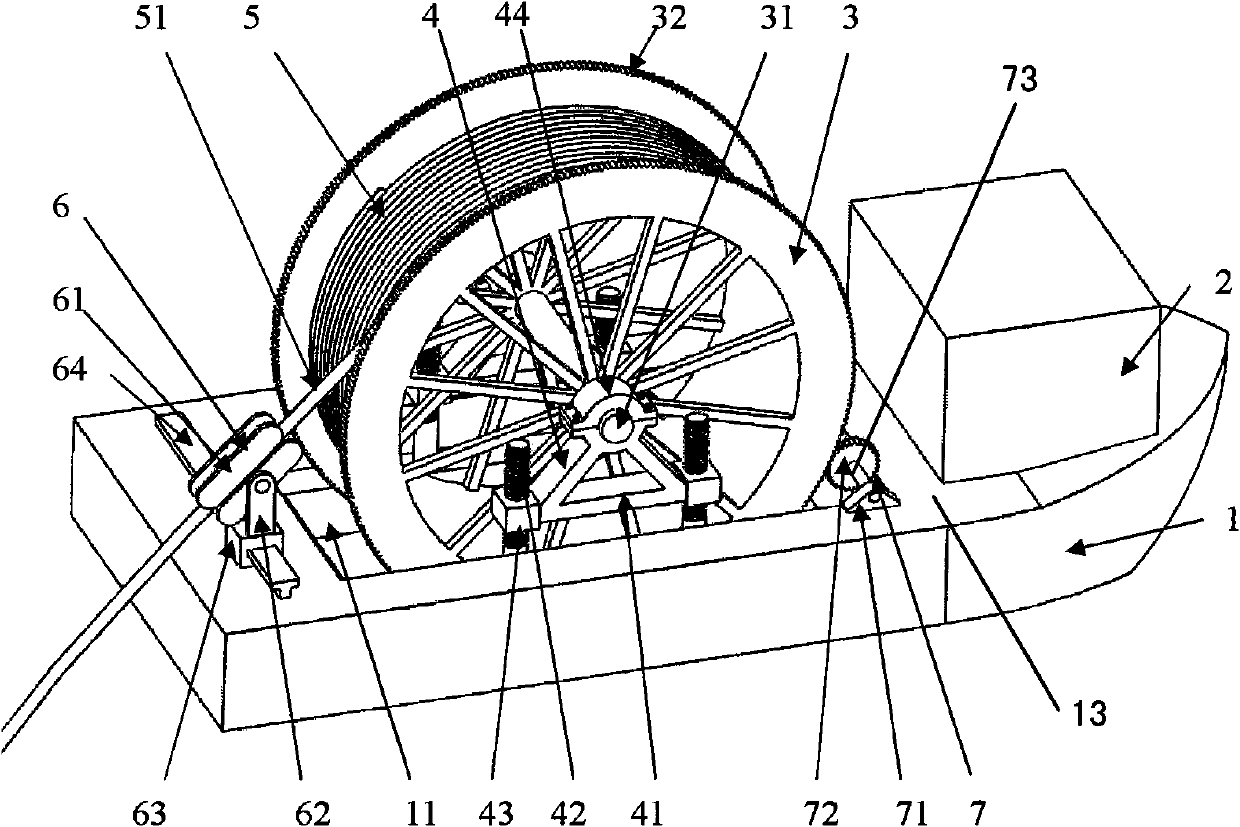

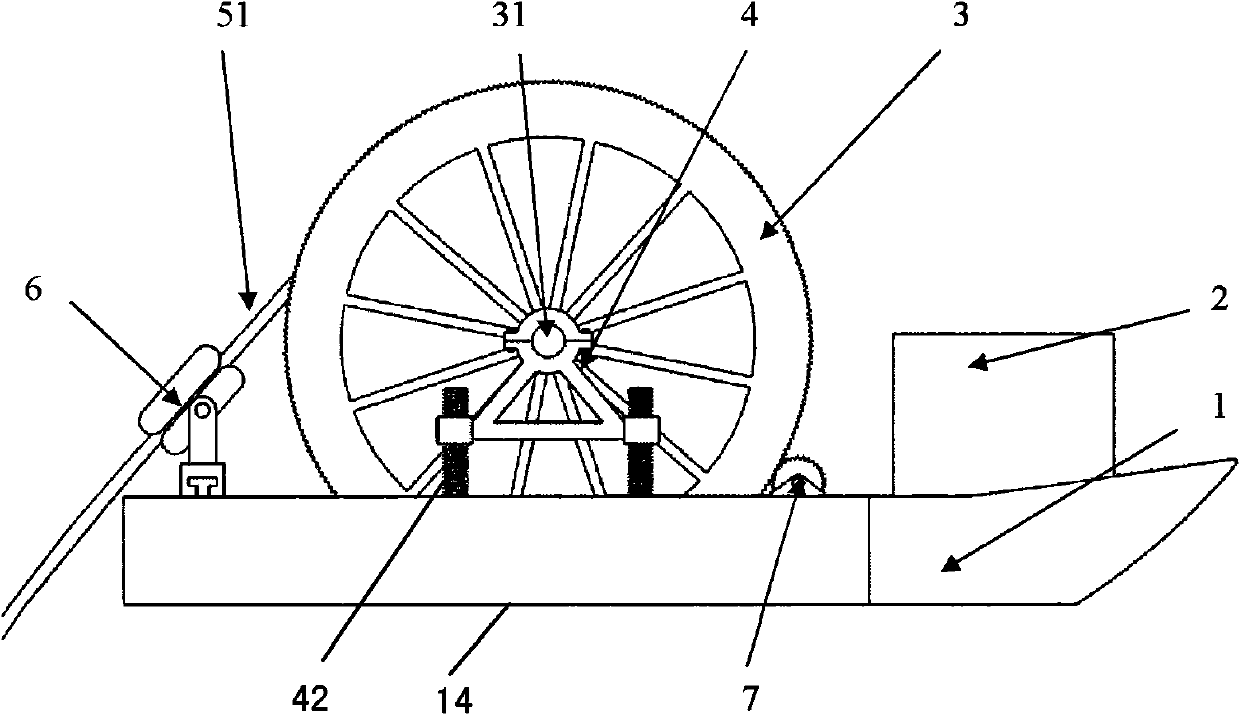

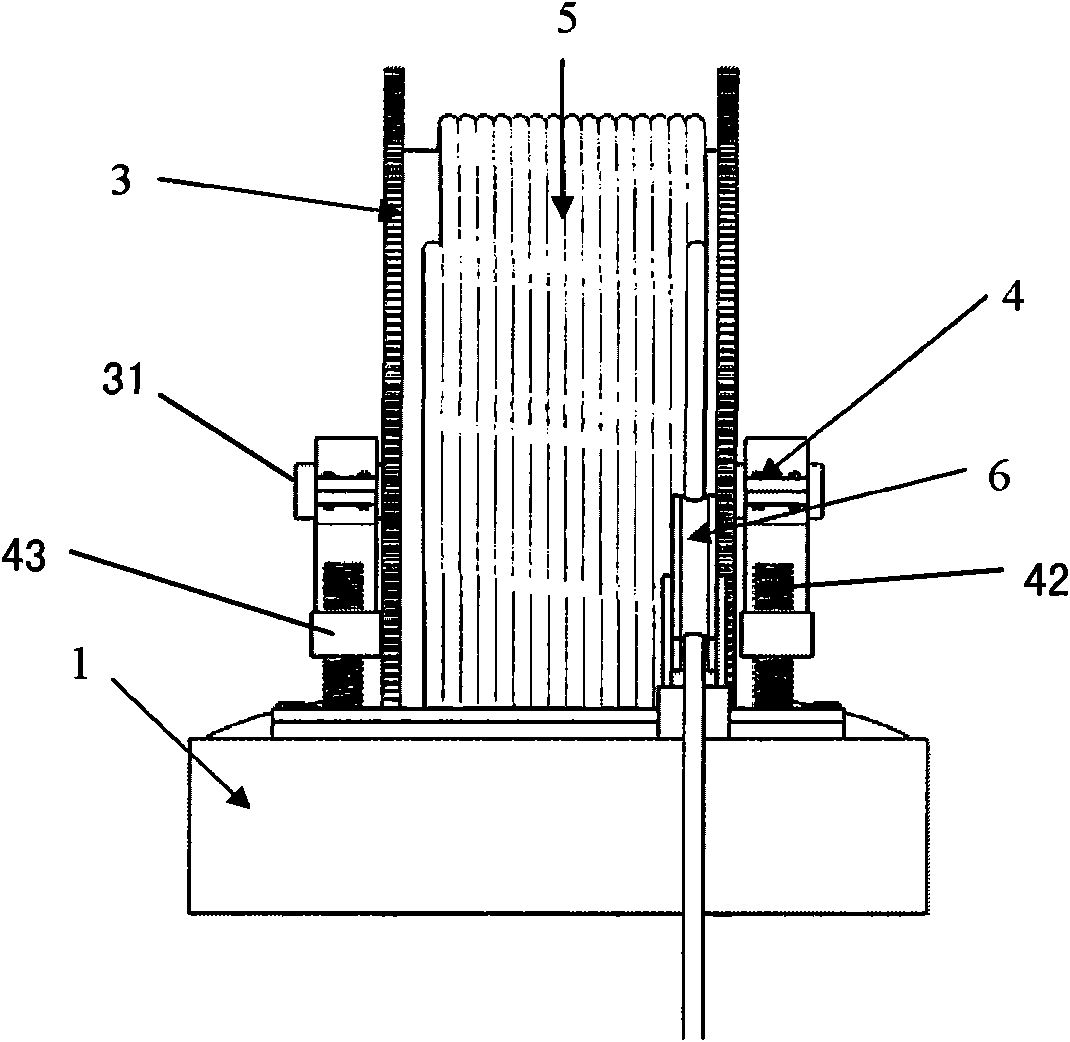

[0023] like Figure 1 to Figure 7 As shown, the reel type subsea pipeline laying operation vessel of the present invention includes a hull 1, a superstructure 2, a reel 3, a reel lifting mechanism 4, a pipeline 5, a pipeline tensioning and straightening mechanism 6 and a reel driving mechanism 7. The hull 1 includes a deck 13 and a bottom shell 14 . Below the deck 13 of the hull, there is a sinking tank 11 for the reel 3 to sink. The sinking tank 11 passes through the deck 13 . The drum lifting mechanism 4 can drive the drum 3 to rise and fall along the sinking groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com