Lever-type connector

A connector and rod-type technology, which is applied in the direction of connection, parts of the connection device, electrical components, etc., can solve problems such as poor release performance, reduced operating efficiency of the operator, and damage to the rod 120

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Next, a lever-type connector according to an embodiment of the present invention will be described with reference to the drawings.

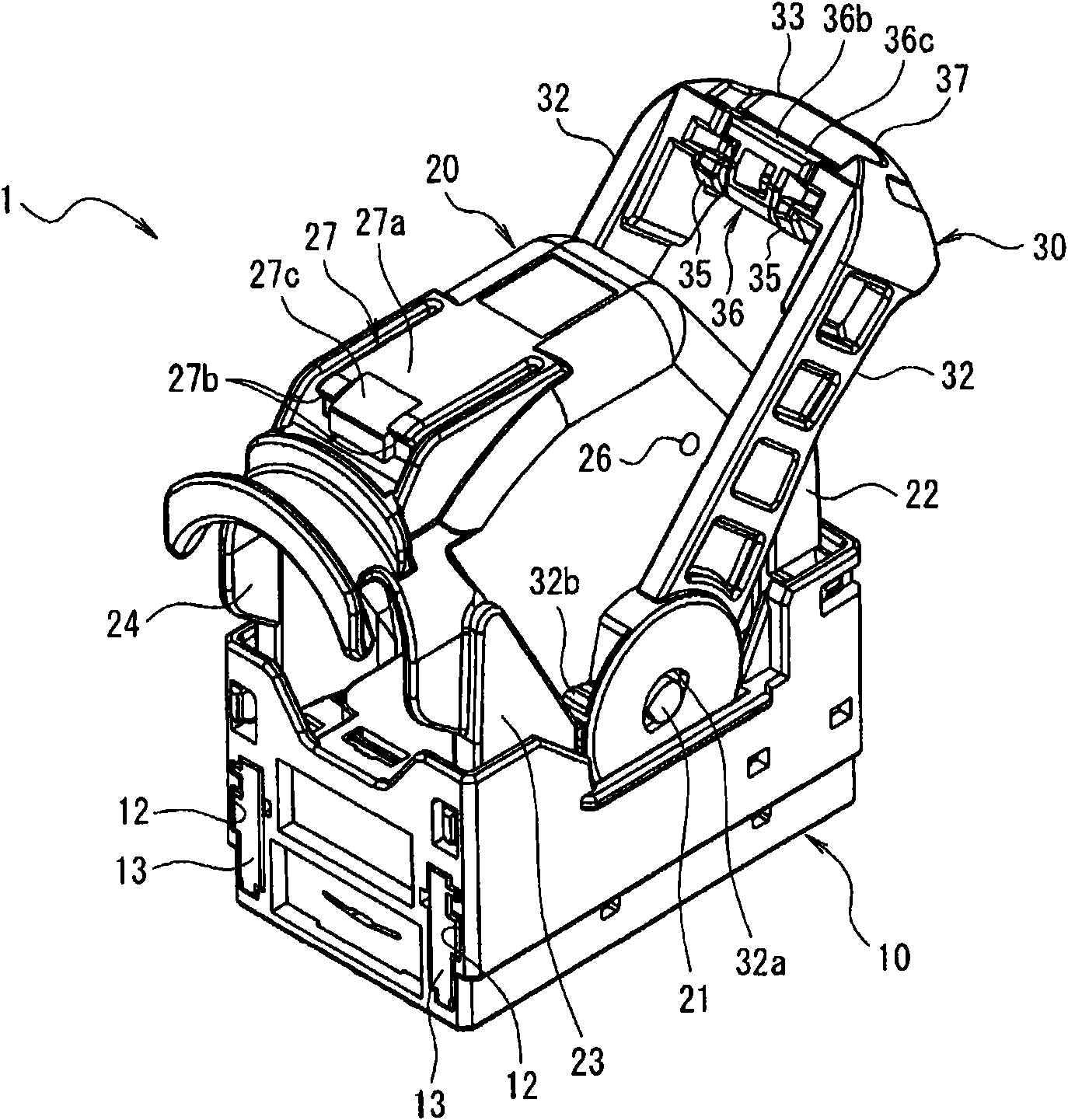

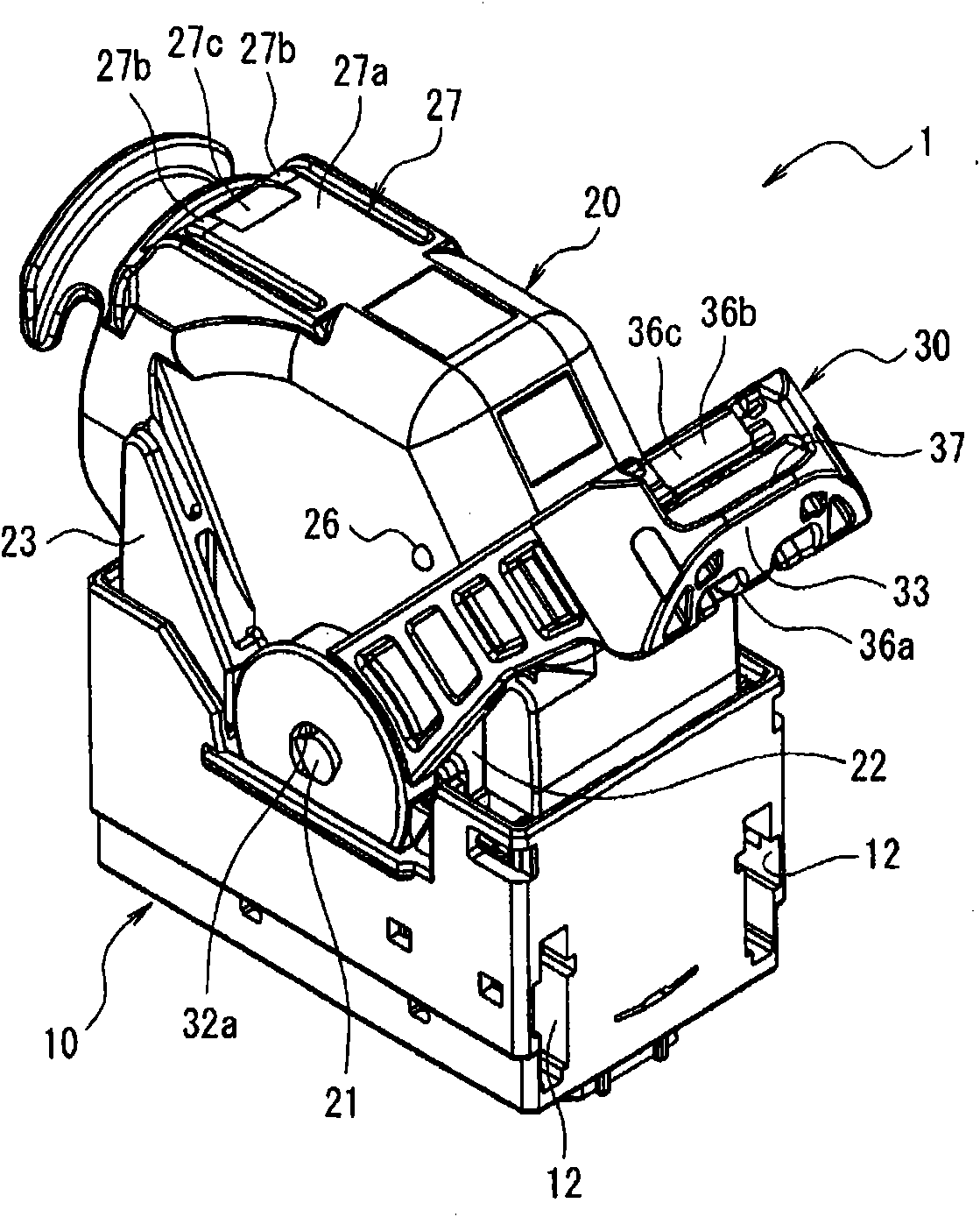

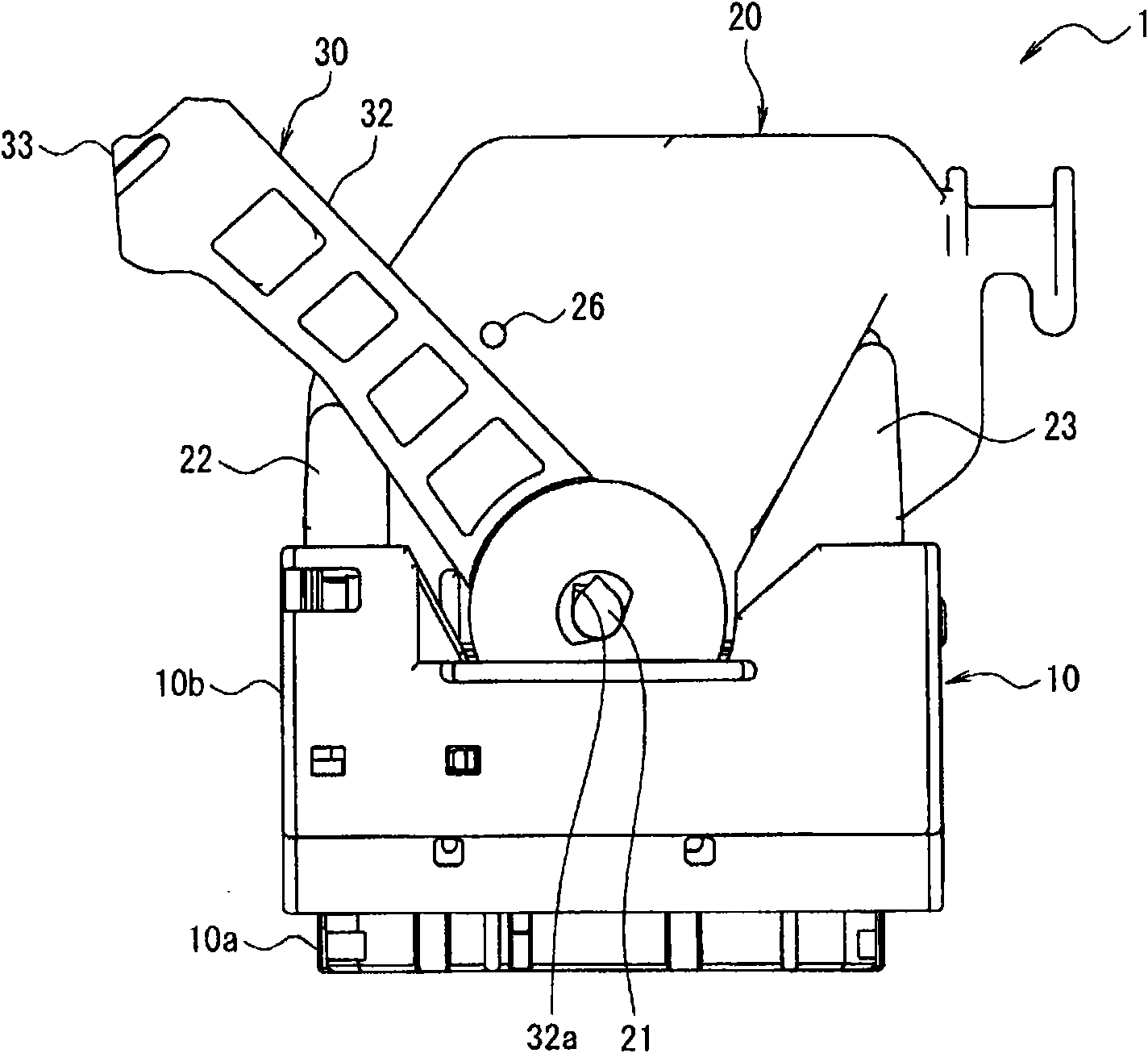

[0088] figure 1 It is a perspective view on the right side showing a state in which the lever of the lever-type connector according to the embodiment of the present invention is arranged at a fitting start position. figure 2 is displayed figure 1 Perspective view of the left side of the rod connector shown. image 3 yes figure 1 Top view of the rod connector shown. Figure 4 yes figure 1 The shown lever connector is a sectional view cut along a line passing through the release portion of the lever. Figure 5 yes figure 1 The lever connector shown is a cross-sectional view cut along a line passing through the locking piece of the lever. Figure 6 yes figure 1 Right side view of the lever connector shown. Figure 7 yes figure 1 Rear view of the rod connector shown. Figure 8 is displayed figure 1 A perspective view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com