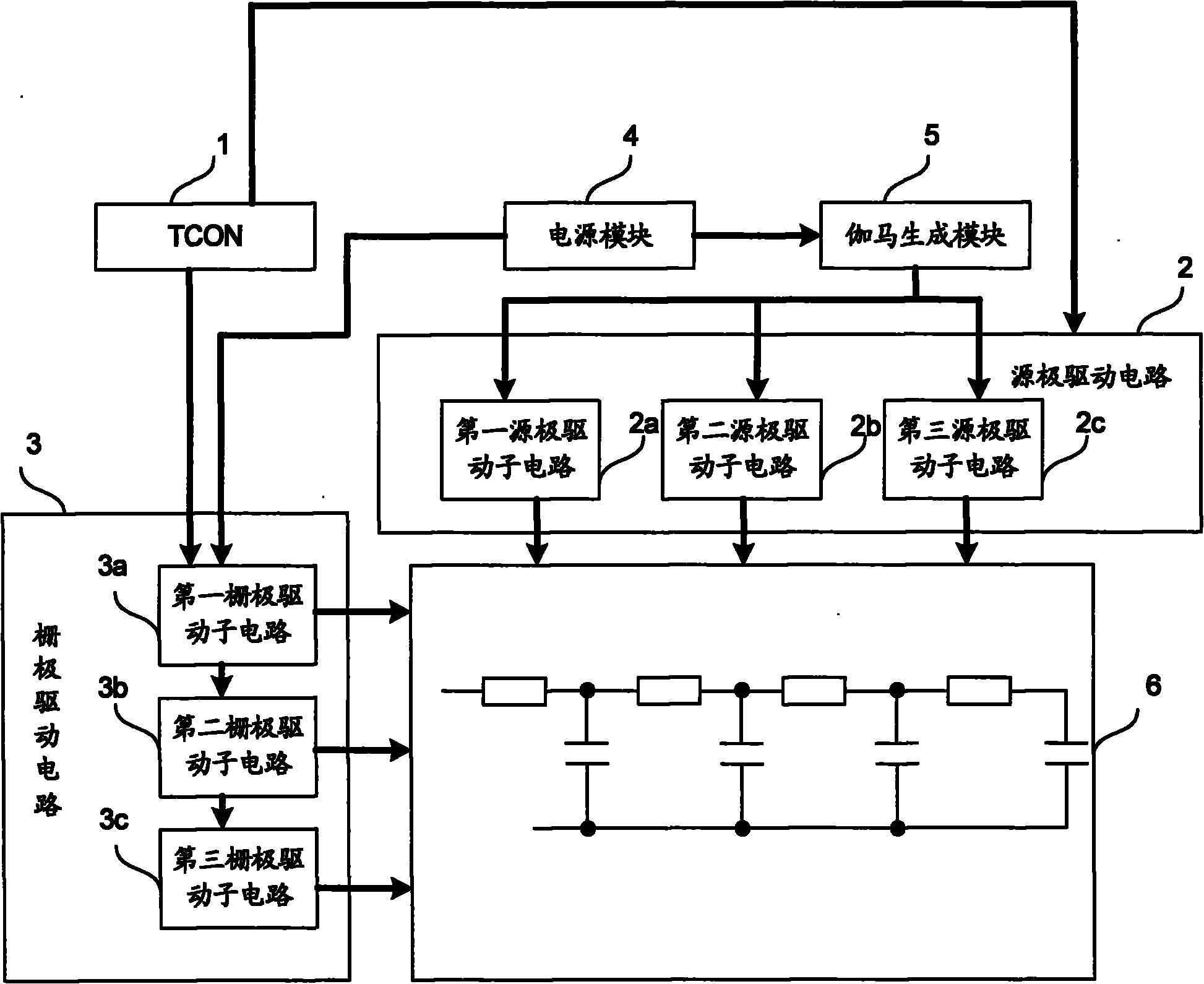

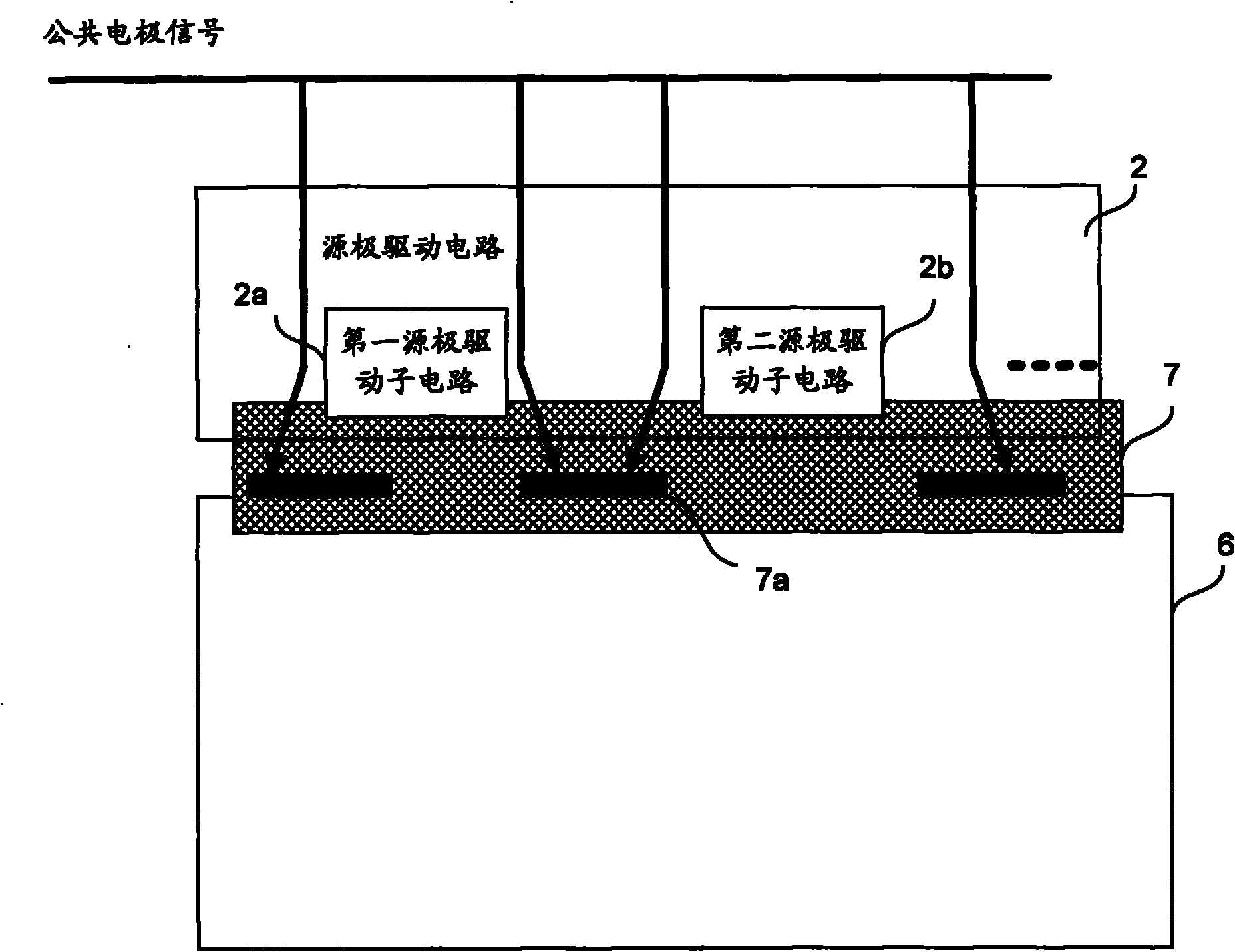

TFT-LCD (Thin Film Transistor-Liquid Crystal Display) drive circuit

A driving circuit and sub-circuit technology, applied in the direction of instruments, static indicators, etc., can solve the problems of not participating in the common electrode signal processing, affecting the screen display, TFT-LCD screen flickering, etc., to reduce the residual DC component and improve the screen display Effect, reduce screen flicker effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

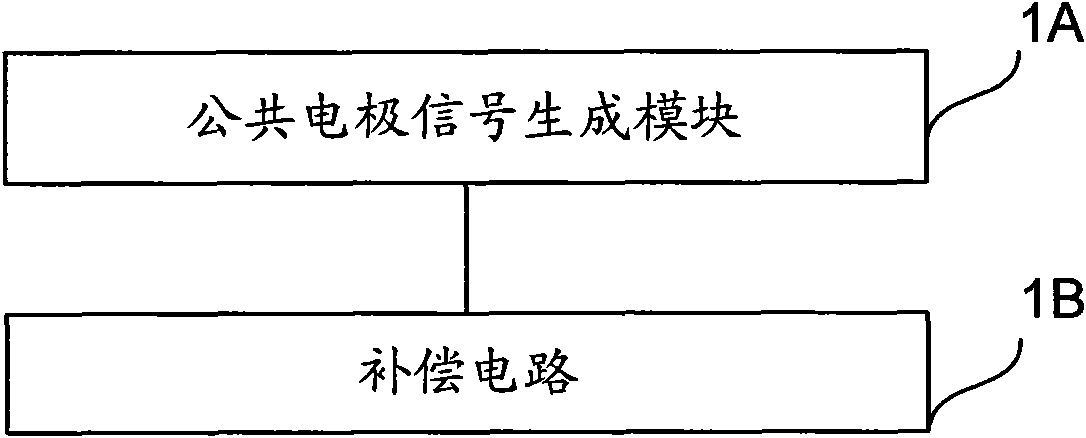

[0026] Such as image 3 Shown is a schematic structural diagram of the TFT-LCD driving circuit of the present invention, the driving circuit includes a common electrode signal generation module 1A and a compensation circuit 1B for generating common electrode signals, and the compensation circuit 1B is connected to the common electrode signal generation module 1A and the panel for use respectively. It is connected to the electrode receiving the common electrode signal, and is used to compensate the voltage on the electrode used to receive the common electrode signal on the panel, so that the voltage on the electrode used to receive the common electrode signal at different positions on the panel reaches its respective target voltage.

[0027] The TFT-LCD driving circuit provided by the present invention adopts a compensation circuit to compensate the voltage on the electrodes on the panel for receiving common electrode signals, so that the voltages on the electrodes at different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com