Device for determining water tightness

A measuring device and water sealing technology, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of not meeting the quality monitoring of sealing at the cut mark of the pull ring of the outer cover, Problems such as slow sealing speed of the outer cover and late detection conclusion have achieved the effect of wide coverage of quality monitoring, low detection cost, and increased detection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

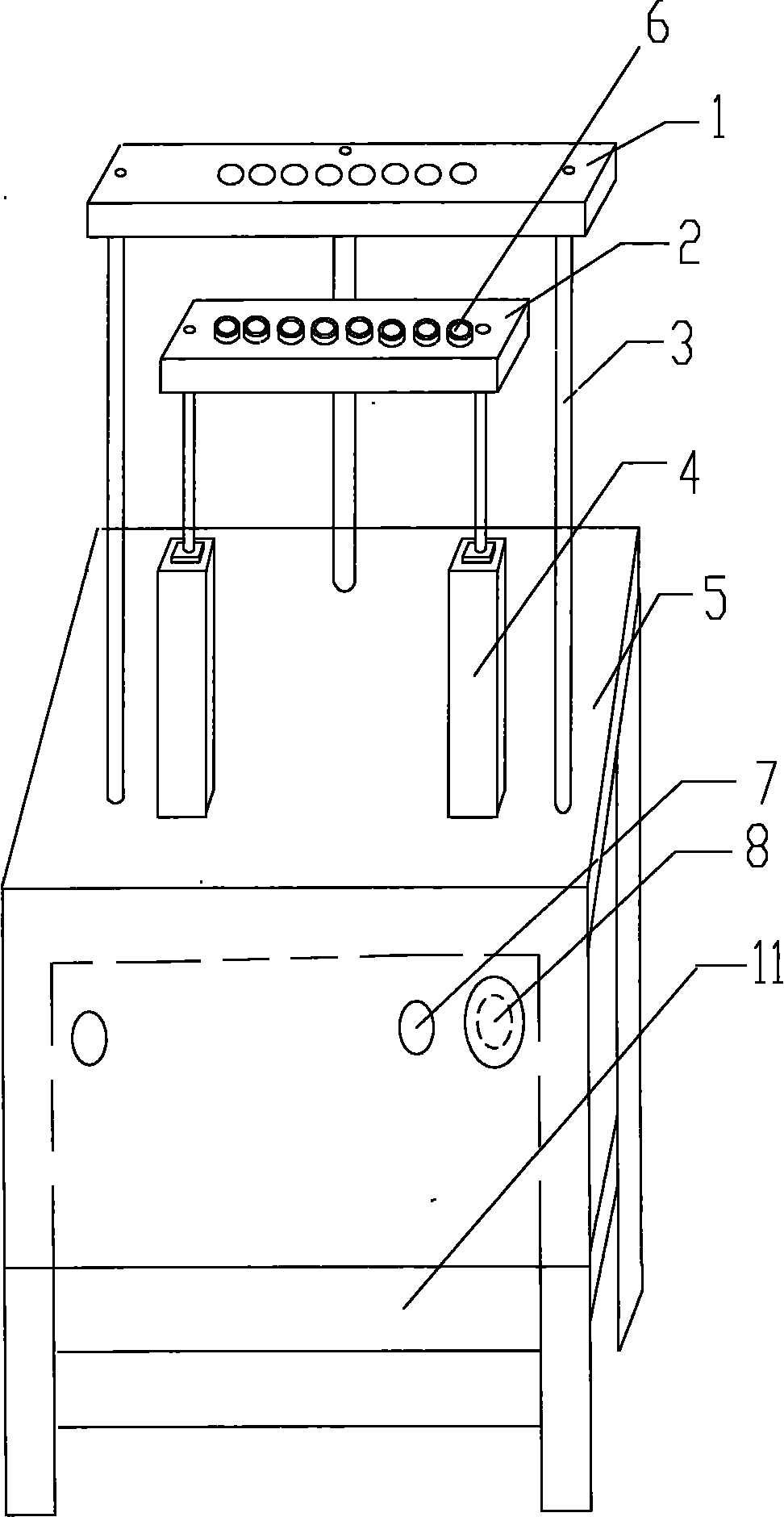

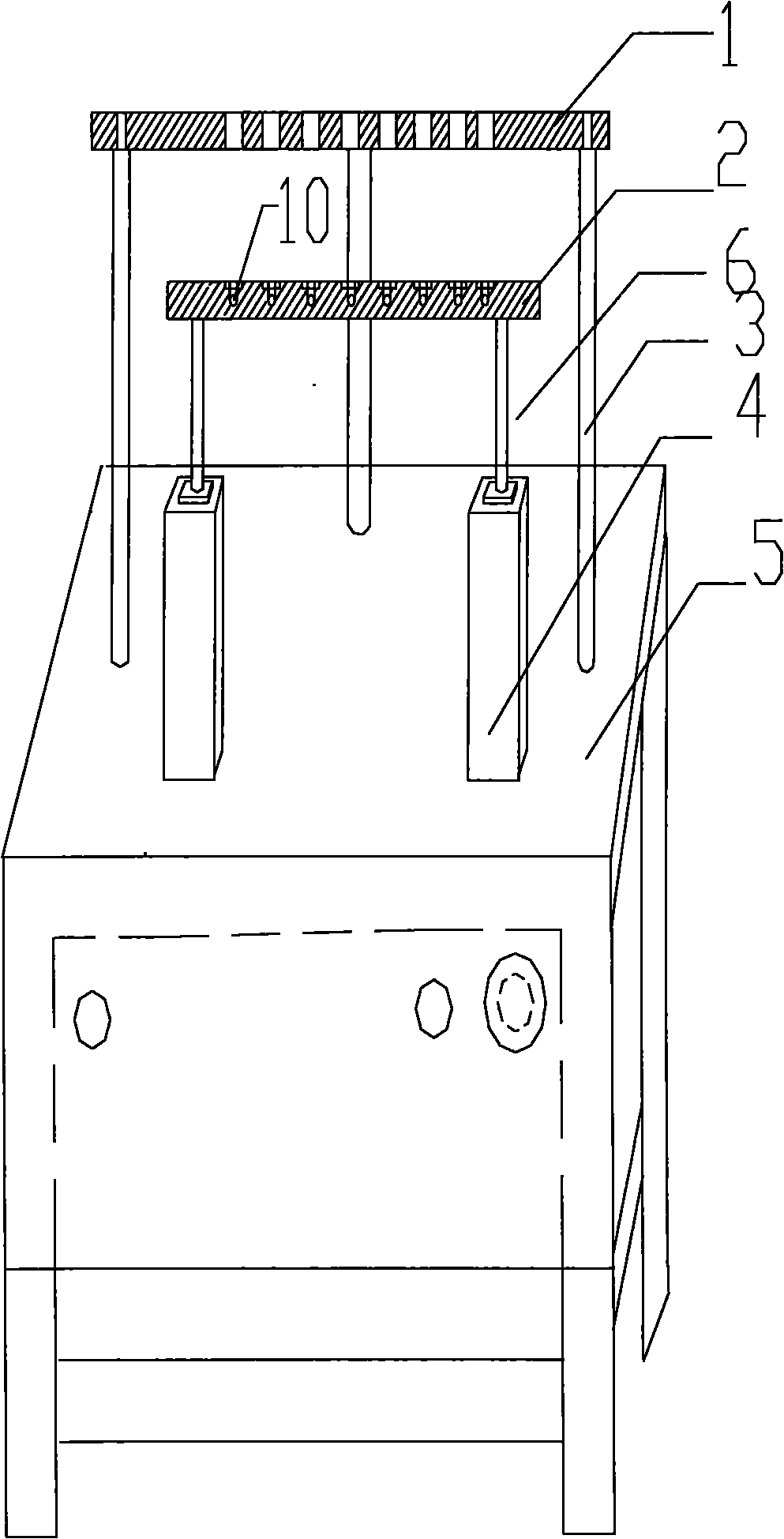

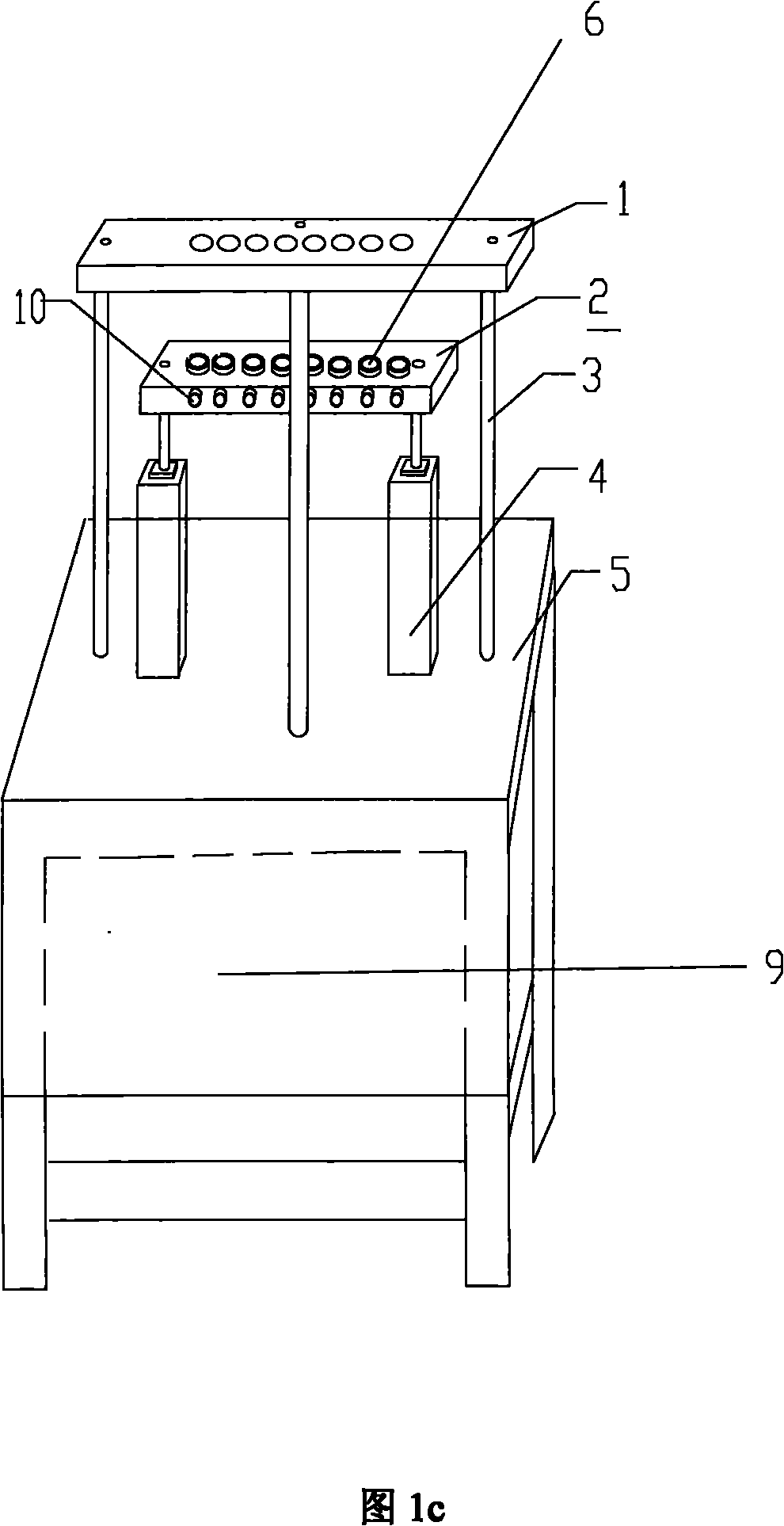

[0016] figure 1 It is a schematic diagram of the device of this invention. The water tightness measuring device of this invention is characterized in that it includes: a positioning plate 1, a detection station support plate 2, a column 3, a cylinder 4, a work surface 5, a gasket hole 6, and a start control button 7. Emergency stop button 8, baffle plate 9, water circulation conduit 10, power supply system 11.

[0017] Two cylinders 4 are fixed on the work table 5 with a height of 900mm to support the detection station support plate 2, and there is a column 3 on both sides of the cylinder 4 and behind the detection station support plate to support the positioning plate 1 with the gasket hole 6; There is a baffle plate 9 connected to the table top inside the work surface 5, two start control buttons 7 and an emergency stop button 8 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com