Method and device for detecting additives, abrasion or corrosion on wall of vibrating tube of Coriolis mass flowmeter

A technology of Coriolis flowmeter and vibrating tube, which is applied in the field of online monitoring of the working state of Coriolis mass flowmeter, on-line calibration and fault diagnosis. , inaccurate, vibrating tube vibrating tube is worn out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

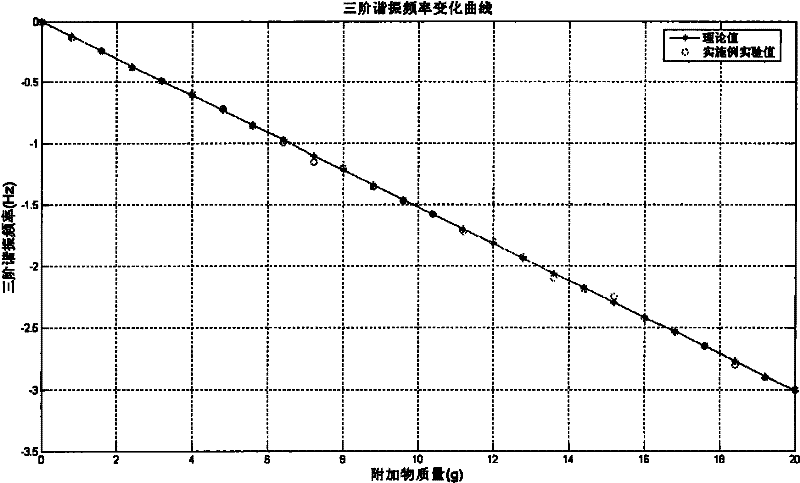

[0032] The third-order resonance frequency of the vibrating tube of the flowmeter is an inherent property of the vibrating tube and is closely related to the structure of the vibrating tube. Under ideal conditions, the motion state of the fluid will not affect the magnitude of the third-order resonance frequency. The third-order resonance frequency is periodically measured and analyzed, which realizes real-time monitoring of the abnormal working state of the vibrating tube of the flowmeter. Since the third-order vibration shape of the vibrating tube is similar to the vibration tube vibration shape caused by Coriolis acceleration, and the working environment of the flowmeter is often a coupling of various influencing factors, in order to improve the accuracy of the solution, in this embodiment, the In order to solve the third-order resonance frequency of the vibrating tube in the static state of the fluid.

[0033] In the application field of Coriolis mass flowmeter, it is diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com