Range hood

The technology of a range hood and a steam engine is applied in the field of kitchen utensils, and can solve the problems of a large space occupied by a range hood, increased maintenance difficulty, and a small range of oil fume absorption, and achieves the effects of being convenient for cleaning and beneficial to exhausting fume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

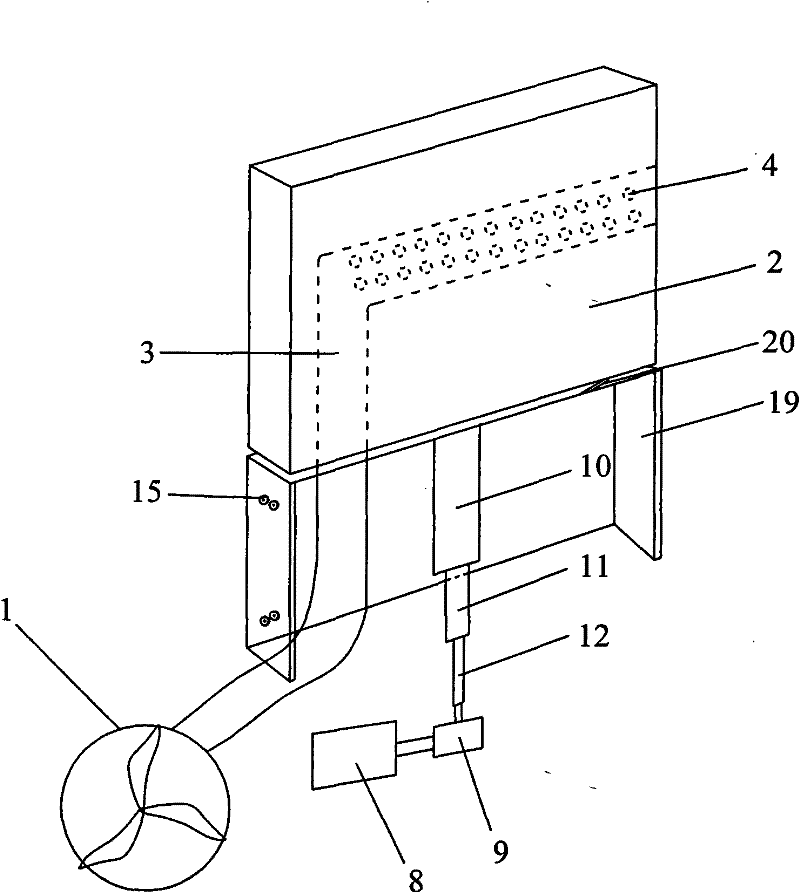

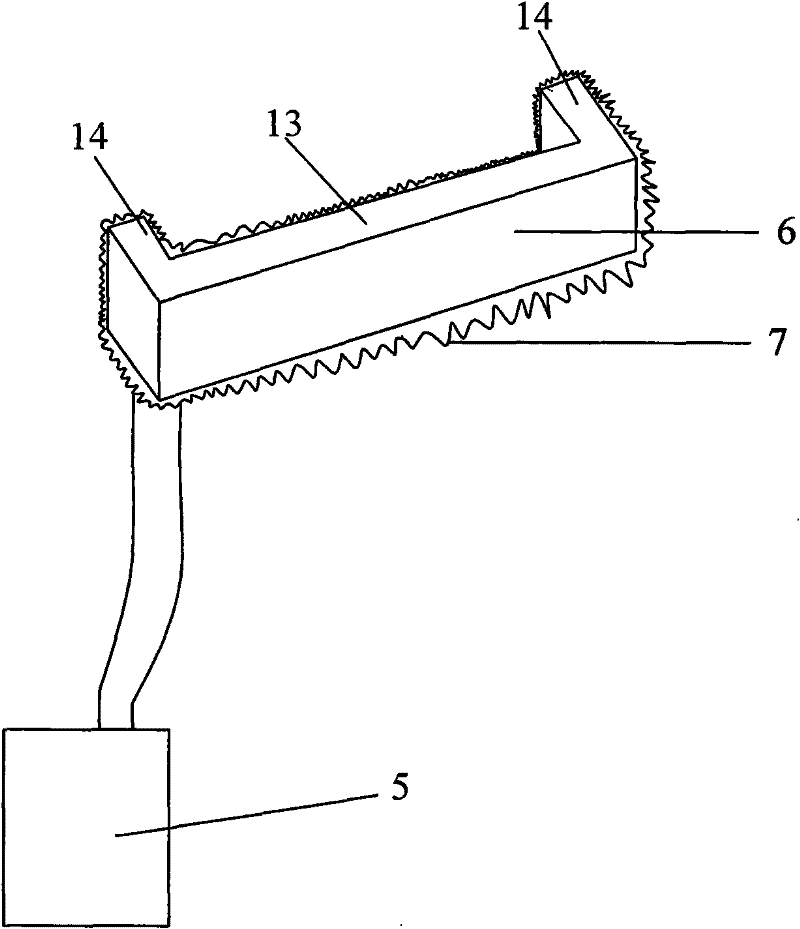

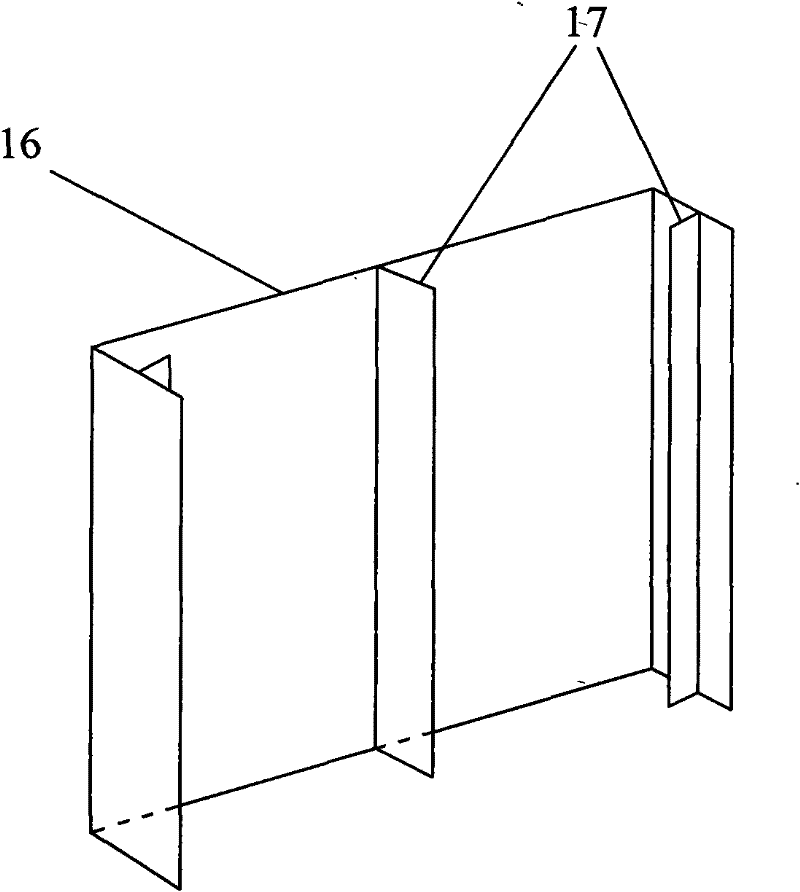

[0022] Such as figure 1 , figure 2 As shown, the range hood of the present invention includes an exhaust fan 1 and a housing 2. The housing 2 is provided with a smoke exhaust pipe 3. One end of the smoke exhaust duct 3 is closed, and the other end communicates with the exhaust fan 1. The smoke pipe 3 is provided with a plurality of small holes 4, and the small holes 4 communicate with the outside world, and the outside world refers to the indoor environment; the range hood also includes a lifting mechanism, and the lifting mechanism and the housing 2 connections.

[0023] The smoke exhaust pipe 3 can be directly made into a pipe shape inside the housing, and at this time, a small hole 4 is directly opened on the housing as a smoking port; a passage for installing the smoke exhaust pipe 3 can also be provided in the housing , and then the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com