Air distribution system of biomass moulding fuel boiler

A molding fuel and air distribution system technology, applied in blast equipment, combustion methods, combustion equipment, etc., can solve the problems of easy combustion, high volatile content, inability to achieve combustion effect, etc., and achieve the effect of reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

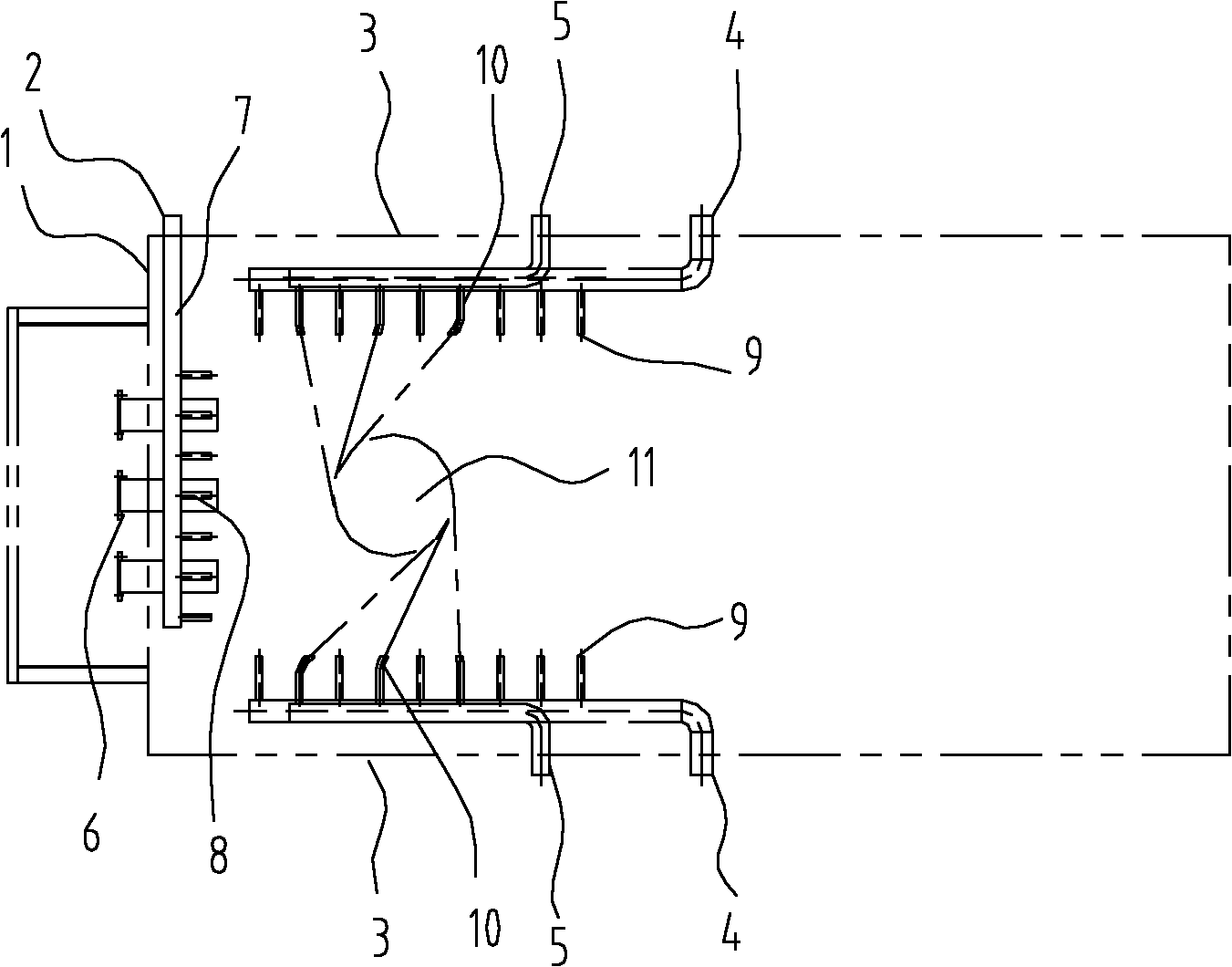

[0022] see figure 1 and figure 2 , the air distribution system of the biomass briquette fuel boiler in this embodiment includes the furnace front air pipe 2 arranged on the boiler front wall 1, the bottom air pipe 4 arranged on the boiler side wall 3, and the swirl air pipe arranged above the bottom air pipe 4 The air duct 5; the air duct 2 in front of the furnace is set at the fuel feeding port 6 of the boiler Below, the furnace front air duct 2 includes a main pipe 7 and branch pipes 8. The main pipe 7 is arranged horizontally, and air outlets formed by seven branch pipes 8 are arranged at intervals on it. The discharge direction of the material port 6; the bottom air pipe 4 is symmetrically arranged on both sides of the boiler, and the bottom air pipe 4 is a direct blowing type and enters the grate surface, and there are nine air outlets 9 on each side; two air outlets 9 above the bottom air pipe 4 The air outlets 10 of the side swirl air duct 5 are set in a swirl direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com