Device for automatically cutting pipe fitting

A cutting and pipe fitting technology, applied in sawing machine, metal processing, metal sawing equipment, etc., can solve the problems of low efficiency and poor operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

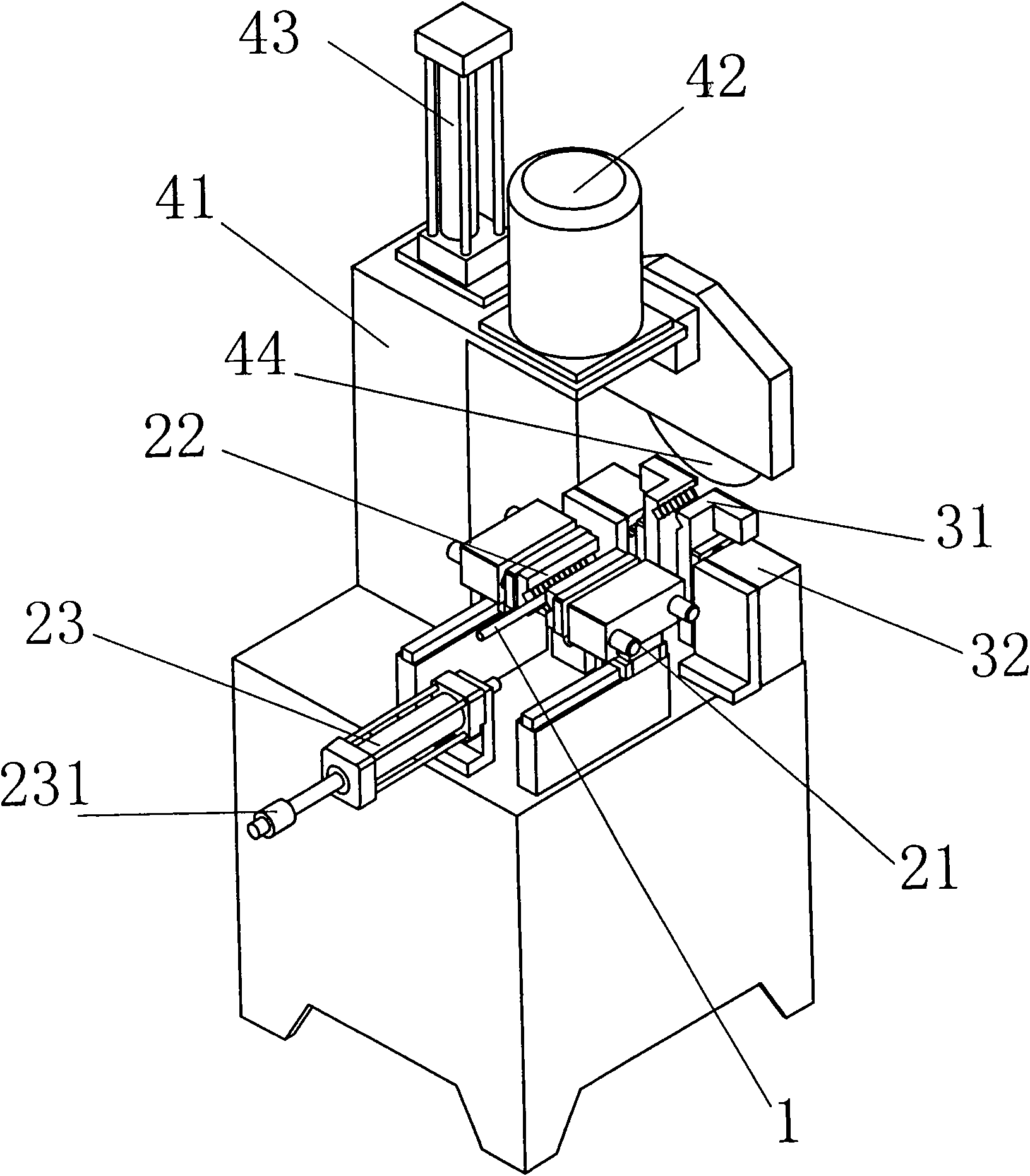

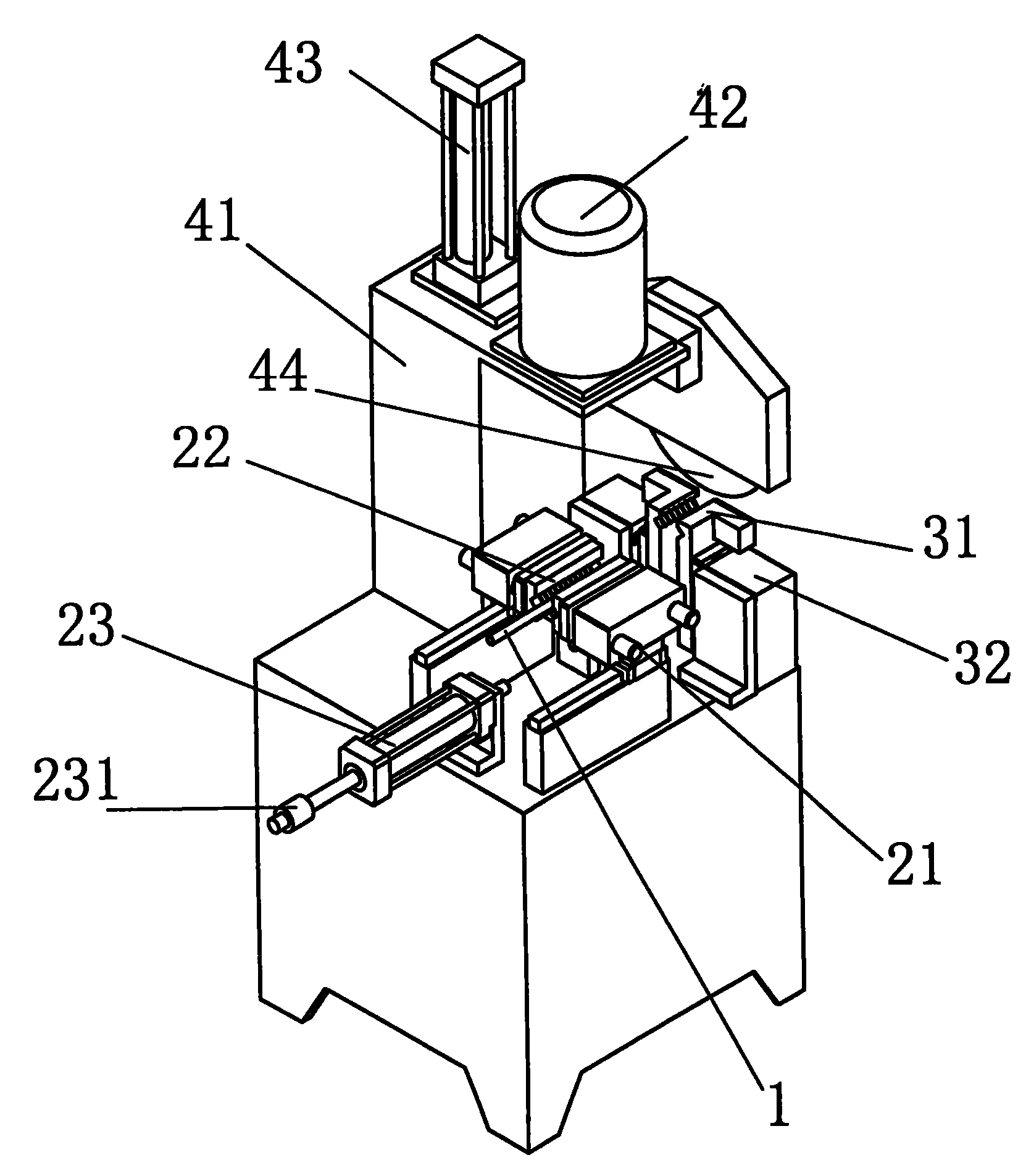

[0014] combine figure 1 , as further described below:

[0015] An automatic cutting device for pipe fittings, which is composed of a feeding mechanism, a clamping mechanism and a cutting mechanism. The material mechanism, the clamping mechanism and the cutting mechanism are arranged side by side, wherein:

[0016] 1) The feeding mechanism includes a sliding clamping mold 22 driven by a sliding clamping cylinder 21 to clamp the pipe fitting 1 and a feeding cylinder 23 that drives the sliding clamping mold 22 to slide. 23 drives to slide along the direction of the fixed clamping die 31, and the feeding cylinder 23 is a double-out rod cylinder, which can adjust the sliding distance with the clamping mechanism (specifically the fixed clamping die 31 described below) through the adjusting nut 231 at the tail;

[0017] 2) The clamping mechanism includes a fixed clamping die 31 capable of clamping the feeding mechanism into the pipe fitting 1 and a fixed clamping cylinder 32 that dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com