Selective flocculation reverse flotation desilication process of collophanite containing primary slime

A technology of reverse flotation desiliconization and colloidal phosphate rock, which is applied in the direction of selective deposition, solid separation, etc., can solve the problems of large temperature influence, large floating amount of flotation concentrate, and low temperature, so as to achieve good adaptability, The effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

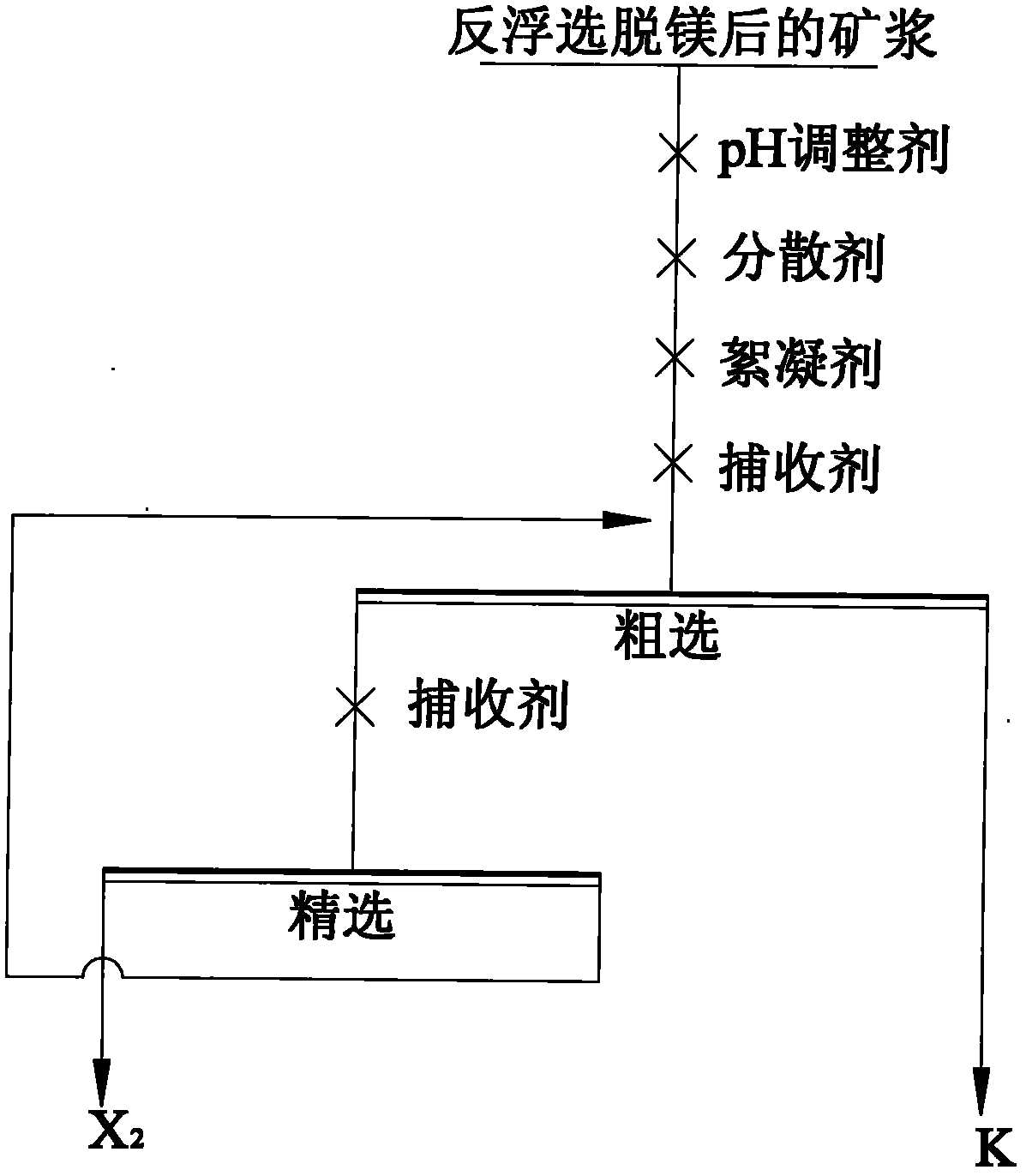

[0031] Example 1. refer to figure 1 . A selective flocculation reverse flotation desiliconization process for collophosite containing primary ore slime, adding a regulator to the pulp after reverse flotation demagnesization of collophosite containing primary ore slime to make the pH of the pulp = 9.5, and then Add dispersant, flocculant and collector for roughing, the roughing tank is concentrated ore; the roughing foam is added to the collector, and then be selected, the selected foam is used as tailings, and the selected tank is returned as middle ore Rough separation; the adjusting agent is sodium hydroxide or sodium carbonate; the dispersant is water glass, the consumption is 1.0kg / t raw ore, or the phosphate of alkali metal, the consumption is 150g / t raw ore; the flocculant It is anionic starch, and the dosage is 200g / t raw ore; the collector is alkyl ether propylamine or alkylpropylenediamine, the rough selection amount is 200g / t raw ore, and the concentration dosage i...

Embodiment 2

[0033] Example 2. refer to figure 2 . A selective flocculation reverse flotation desiliconization process for collophosite containing primary ore slime, adding a regulator to the pulp after reverse flotation demagnesium containing collophosite containing primary ore slime to make the pH of the pulp = 10.5, and then Add dispersant, flocculant, and collector for roughing, and the roughing tank is the concentrate; after the roughing foam is added with the collector, it is selected, and the selected foam is used as tailings, and the selected tank is used as middle ore and The concentrate in the roughing tank is combined into a mixed phosphorus concentrate; the regulator is sodium hydroxide or sodium carbonate; the dispersant is water glass, and the dosage is 3.0kg / t raw ore, or the phosphate of alkali metal, the dosage is 750g / t raw ore; the flocculant is anionic starch, the dosage is 1000g / t raw ore; the collector is alkyl ether propylamine or alkyl propylenediamine, the rough...

Embodiment 3

[0034] Example 3. refer to figure 1 . A selective flocculation reverse flotation desiliconization process for collophosite containing primary ore slime, adding a regulator to the pulp after reverse flotation demagnesization of collophosite containing primary ore slime to make the pH of the pulp = 9.9, and then Add dispersant, flocculant and collector for roughing, the roughing tank is concentrated ore; the roughing foam is added to the collector, and then be selected, the selected foam is used as tailings, and the selected tank is returned as middle ore Rough selection; the adjusting agent is sodium hydroxide or sodium carbonate; the dispersant is water glass, the consumption is 1.8kg / t raw ore, or the phosphate of alkali metal, the consumption is 400g / t raw ore; the flocculant It is anionic starch, and the dosage is 580g / t raw ore; the collector is alkyl ether propylamine or alkylpropylenediamine, the rough selection amount is 350g / t raw ore, and the concentration dosage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com