Wet ammonia flue gas desulphurization product drying, cooling and conveying linkage process and equipment

A technology of drying and cooling, flue gas, applied in separation methods, ammonium sulfate, chemical instruments and methods, etc., can solve the problem of not specifically mentioning the deep drying process of ammonium sulfate, etc., to achieve effective no power consumption heat, reduce Initial investment and total operating costs, the effect of utilizing heat without power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

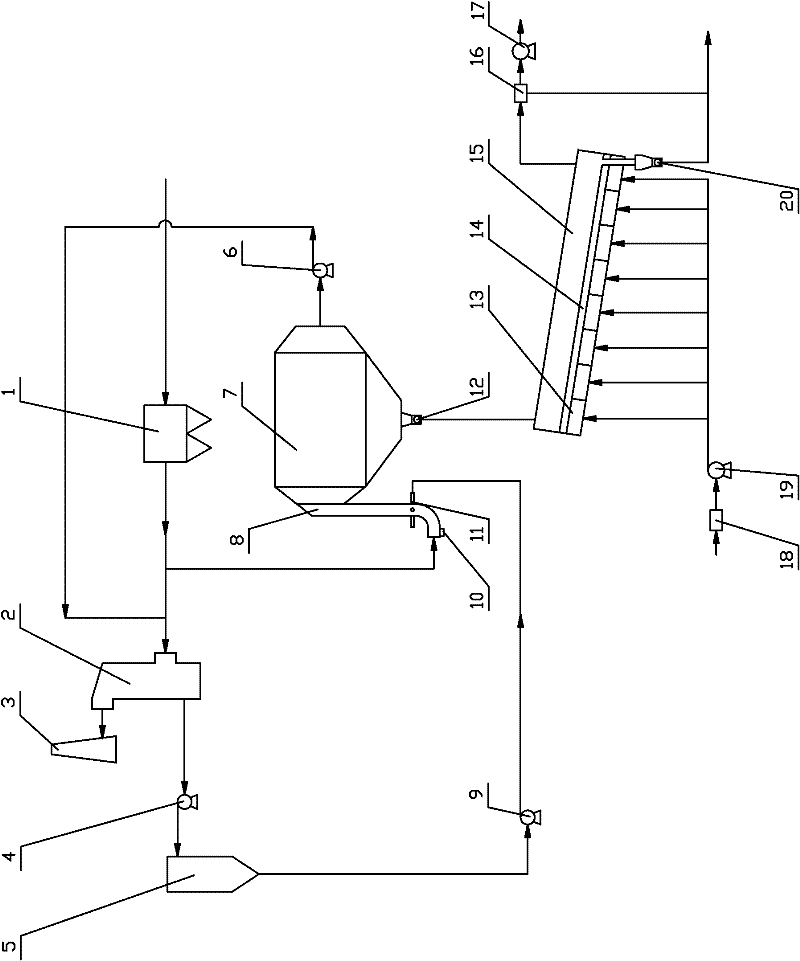

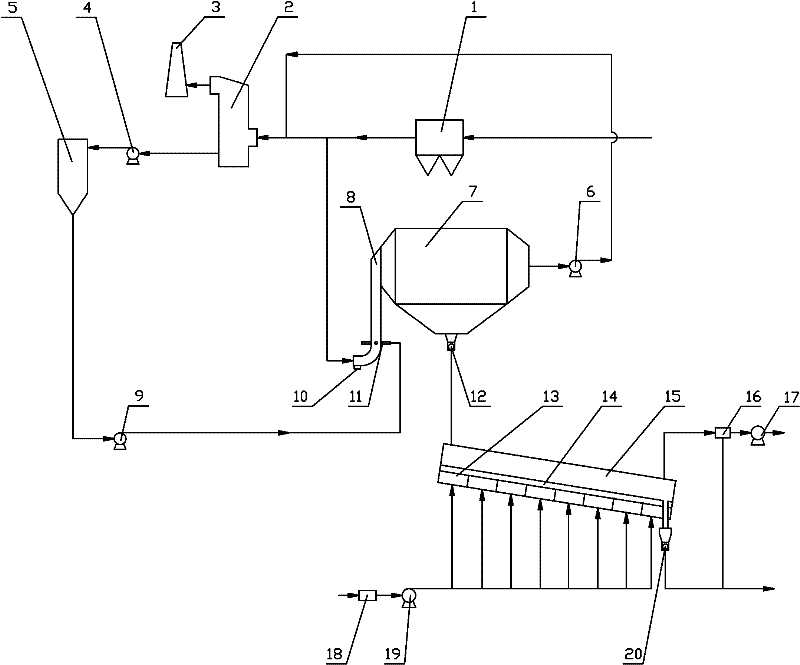

[0029] The equipment and process of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Shown in the figure is a wet ammonia flue gas desulfurization product drying, cooling and conveying linkage equipment that cooperates with the front pre-dust collector 1, desulfurization tower 2 and cyclone separator 5 in the wet ammonia flue gas desulfurization system. The equipment is mainly composed of pre-flue drying device, gas-solid separation device and fluidized chute conveying device. The structure of each part of the device is described as follows.

[0031] The pre-flue drying device includes a vertical flue 8, a number of anti-blocking spray guns 11 are evenly distributed around the lower inner wall of the vertical flue 8, and the input end of the anti-blocking spray gun 11 passes through the connection between the slurry delivery pump 9 and the cyclone separator 5. connected to the outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com