Lactobacillus casei-containing active lactobacillus beverage and preparation method thereof

A technology of active lactic acid bacteria and Lactobacillus casei, applied in the field of fermented dairy product processing, can solve the problems of increasing the risk of fermentation, contamination of fermentation liquid, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

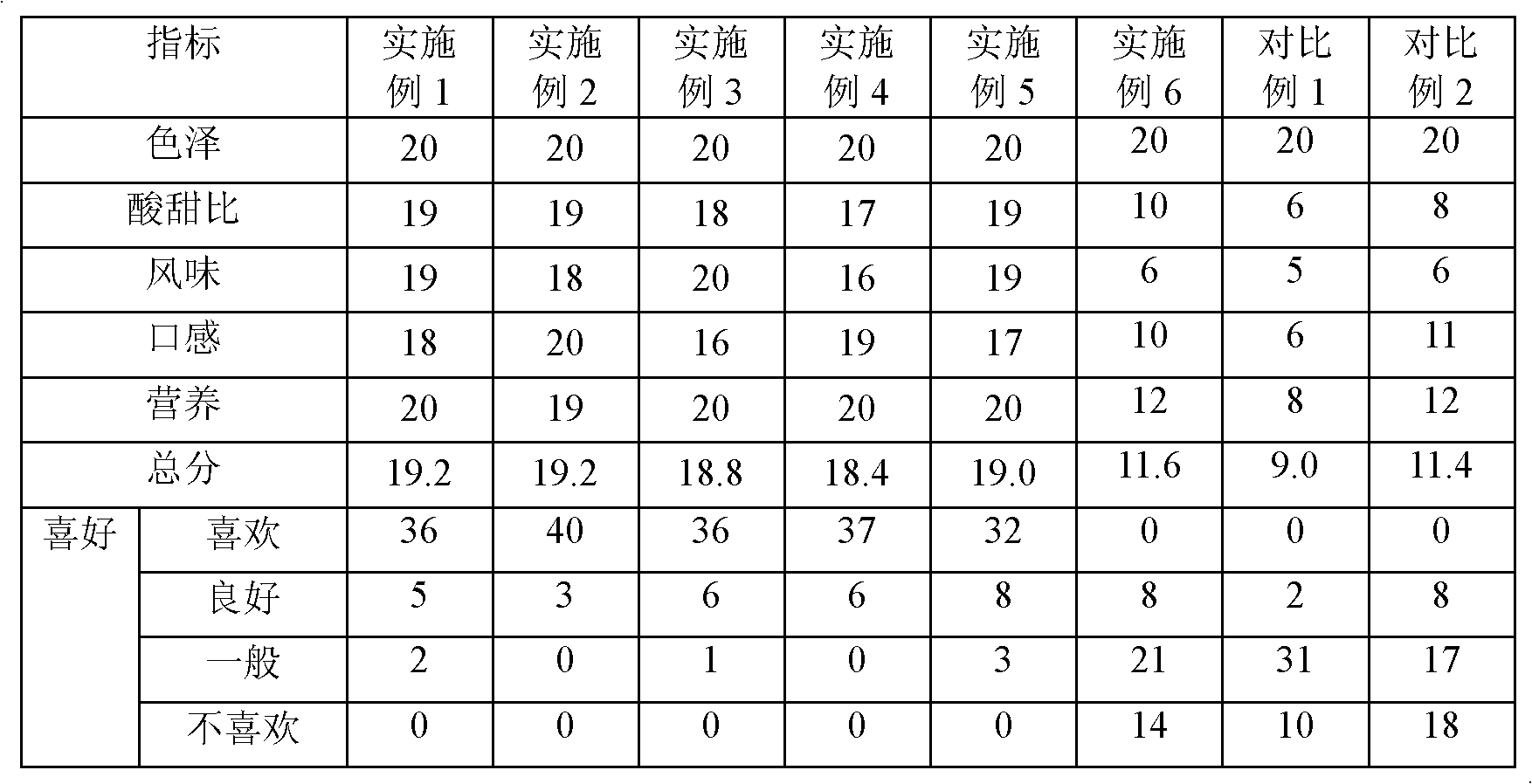

Examples

Embodiment 1

[0037] 1. Raw material formula (calculated in 1000 grams)

[0038] 1. Yogurt base: 100 grams of skimmed milk powder; 5 grams of soybean protein isolate powder; 10 grams of glucose; 40 grams of white sugar; 0.0001 g of Lactobacillus casei strain (Hansen L. casei-01);

[0039] 2. Beverage formula: 300 grams of yogurt base; 130 grams of white sugar; 3 grams of pectin; the remaining water.

[0040] 2. Production method:

[0041] 1. Yogurt base:

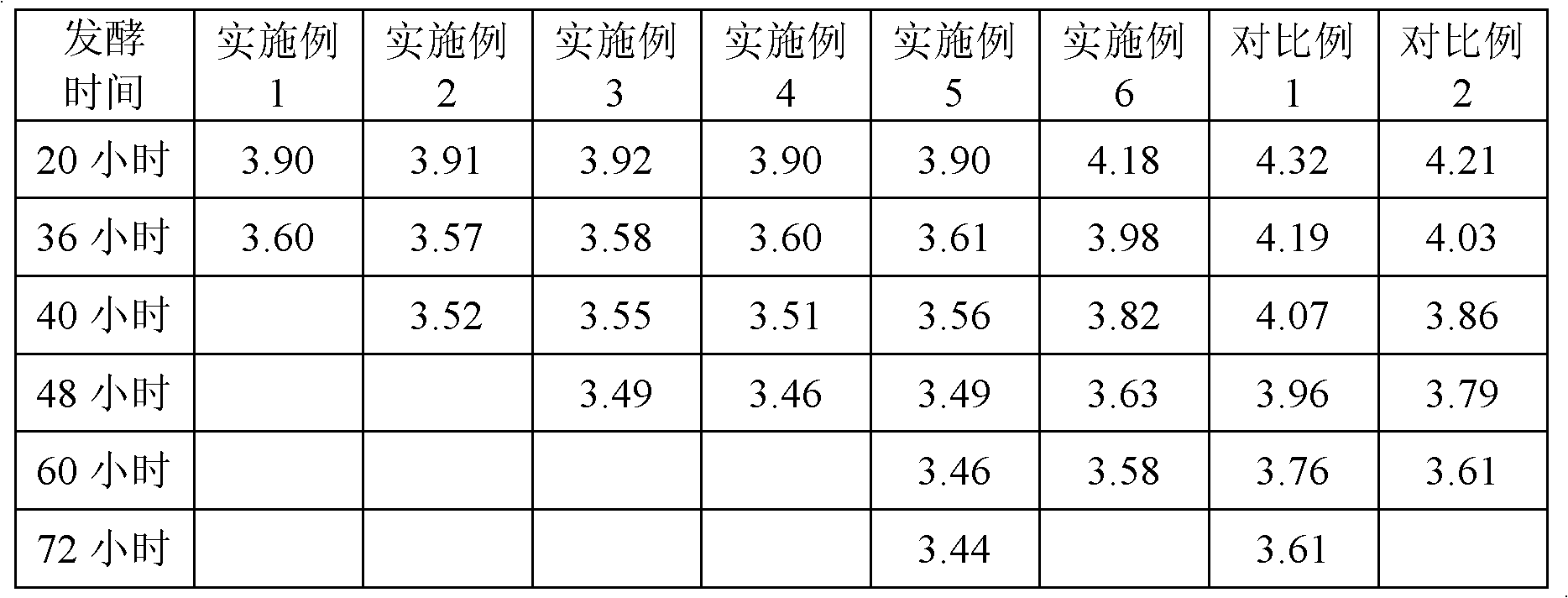

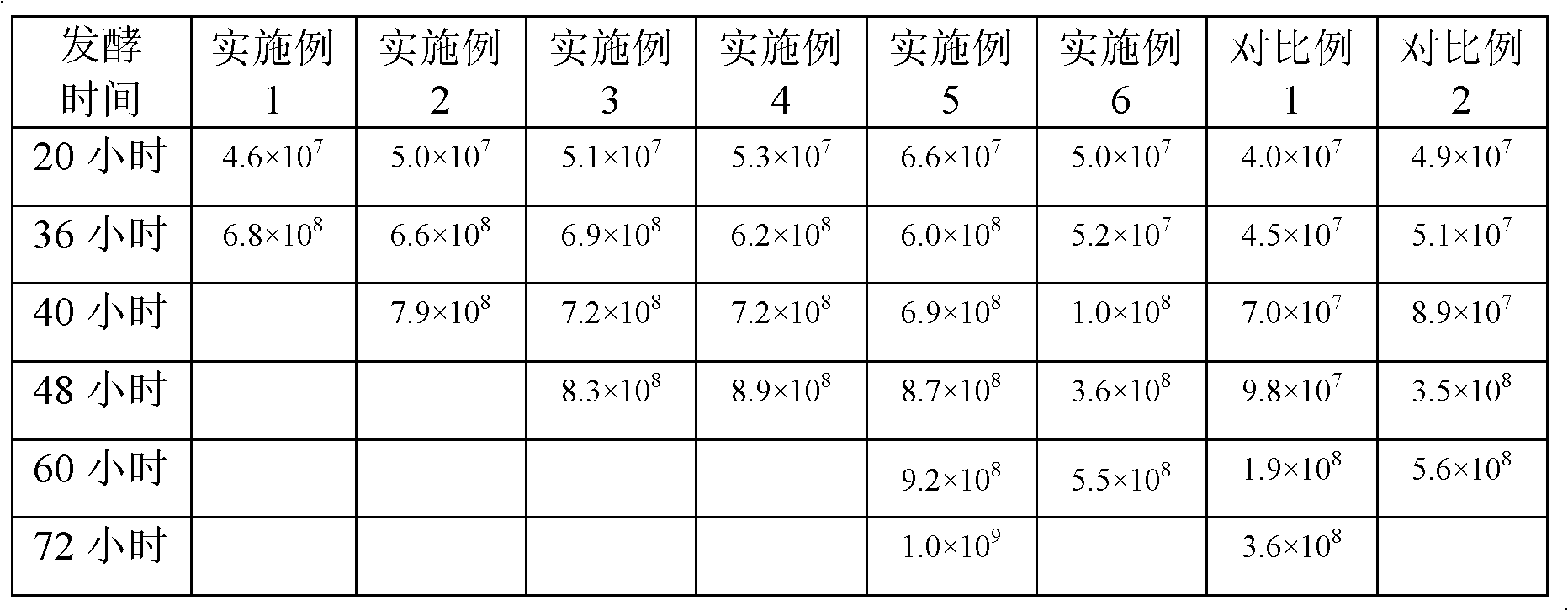

[0042] Mix milk powder, soybean protein powder, white sugar and water well at 50°C; add glucose, then homogenize at 50°C and 15MPa pressure, and sterilize at 100°C for 120 minutes; then cool to 36°C, add Fermentation strain fermentation (initial addition of Lactobacillus casei was 2.0×10 7 cfu / g); fermented at 36°C for 36 hours, when the pH value was 3.60, cooled to below 20°C to break the emulsion and stop the fermentation to obtain the yoghurt base material for use.

[0043] 2. Milk drink production method:

[0044] Mix white sugar...

Embodiment 2

[0047] 1. Raw material formula (calculated in 1000 grams)

[0048] 1. Yogurt base material: 160 grams of skim milk powder; 10 grams of soybean protein isolate; 15 grams of glucose; 50 grams of white sugar; 0.0001 g of Lactobacillus casei (Hansen L. casei-01);

[0049] 2. Beverage formula: 200 grams of yogurt base; 160 grams of white sugar; the remaining water.

[0050] 2. Production method:

[0051] 1. Yogurt base:

[0052] Mix milk powder, soybean protein powder, white granulated sugar, and glucose with water at 52°C; then homogenize at 52°C and 20 MPa pressure, and sterilize at 90°C for 150 minutes; then cool to 37°C and add fermentation Strain fermentation (the initial addition of Lactobacillus casei was 2.0×10 7 cfu / g); fermented at 37°C for 40 hours, when the pH value was 3.52, cooled to below 20°C to stop the fermentation, and obtained the yoghurt base material for use.

[0053] 2. Milk drink production method:

[0054] Dissolve white sugar in water to obtain sugar ...

Embodiment 3

[0057] 1. Raw material formula (Based on 1000 grams)

[0058] 1. Yogurt base material: 902 grams of fresh milk; 8 grams of soybean protein isolate; 30 grams of fructose syrup; 60 grams of white sugar;

[0059] 2. Beverage formula: 350 grams of yogurt base; 120 grams of white sugar; 5 grams of PGA; the remaining water.

[0060] 2. Production method:

[0061] 1. Yogurt base:

[0062] Dry mix soybean protein powder and white sugar, dissolve in fresh milk at 58°C, add syrup, and mix well; then homogenize at 58°C and 25MPa pressure, and sterilize at 120°C for 10 minutes; then cool to 37°C ℃, add fermentation strain fermentation (the initial addition amount of Lactobacillus casei is 2.0 × 10 7 cfu / g); fermented at 37°C for 45 hours, and when the pH value was 3.51, the fermentation was stopped by cooling to obtain the yogurt base material, which was set aside.

[0063] 2. Milk drink production method:

[0064] Mix white sugar and stabilizer evenly at 80°C, dissolve in water to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com