Back drilling method of through via, circuit board and manufacturing method of circuit board

A manufacturing method and circuit board technology, applied in the directions of printed circuit manufacturing, circuits, printed circuits, etc., can solve the problem that the digital receiver is difficult to determine whether it is received or not, and achieve the effect of reducing back-drilling errors and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

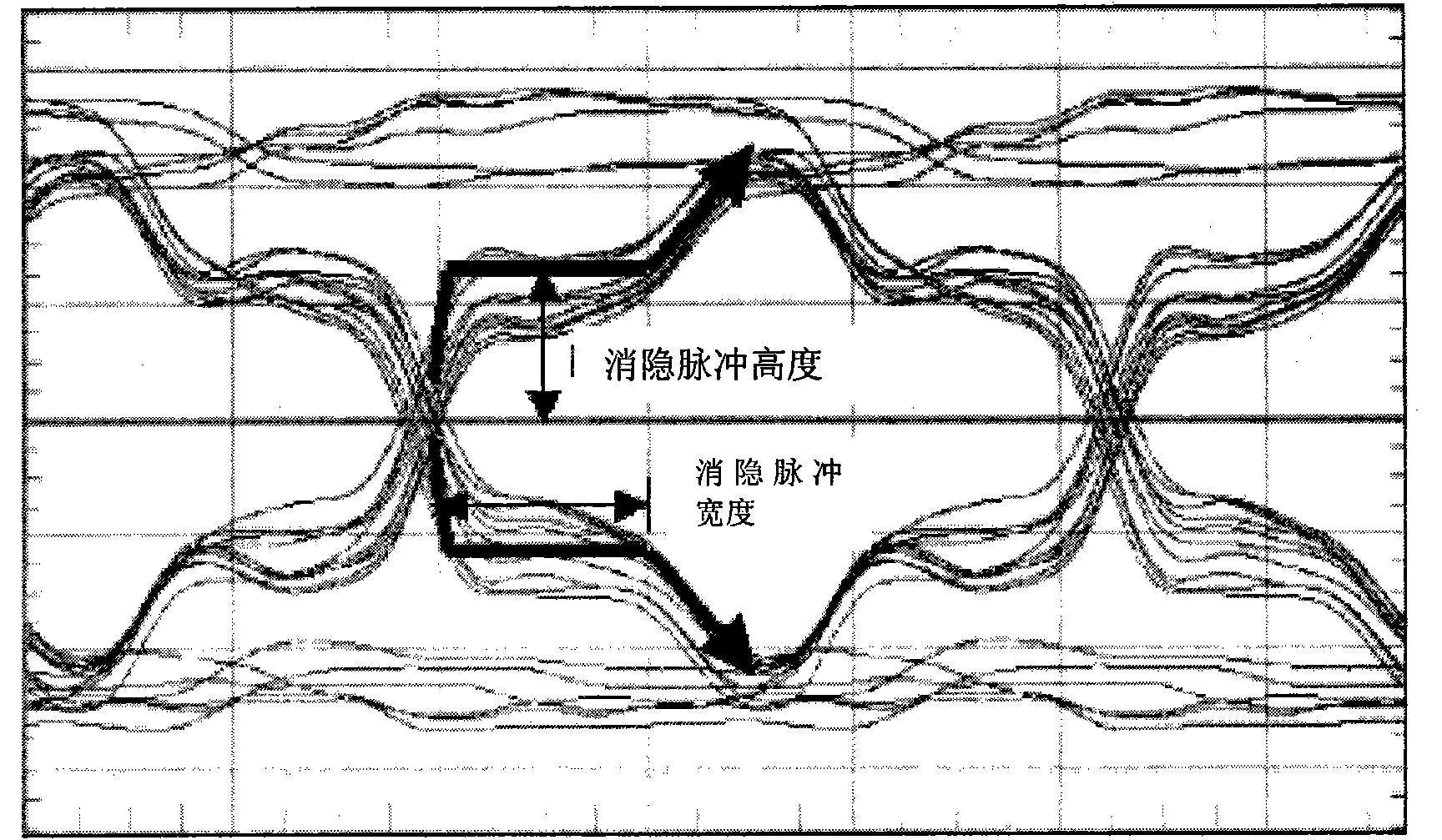

Problems solved by technology

Method used

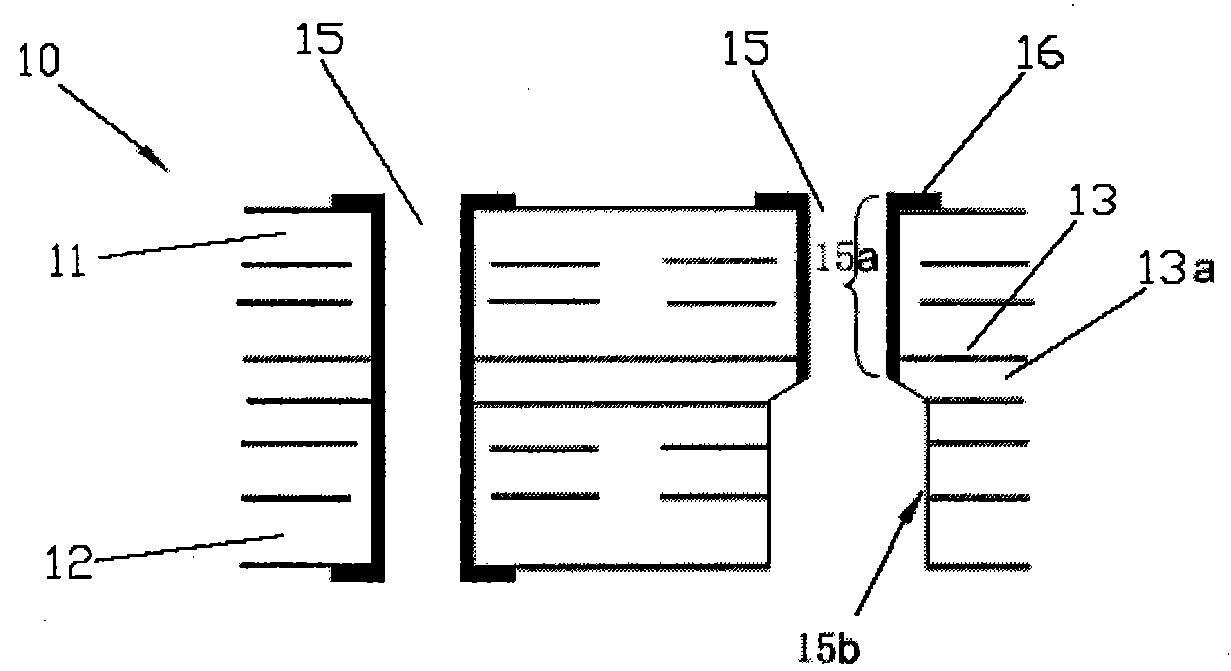

Image

Examples

Embodiment Construction

[0035] The content disclosed in this application does not limit the subject matter of this application or the detailed description of this application. The subject matter of the application is set forth in the detailed description of the application and in the appended claims. Other aspects of the subject matter of the present application will be obvious to those of ordinary skill in the art after reading and understanding the following detailed description and referring to the accompanying drawings, and will not constitute a limitation to the present invention in a certain sense.

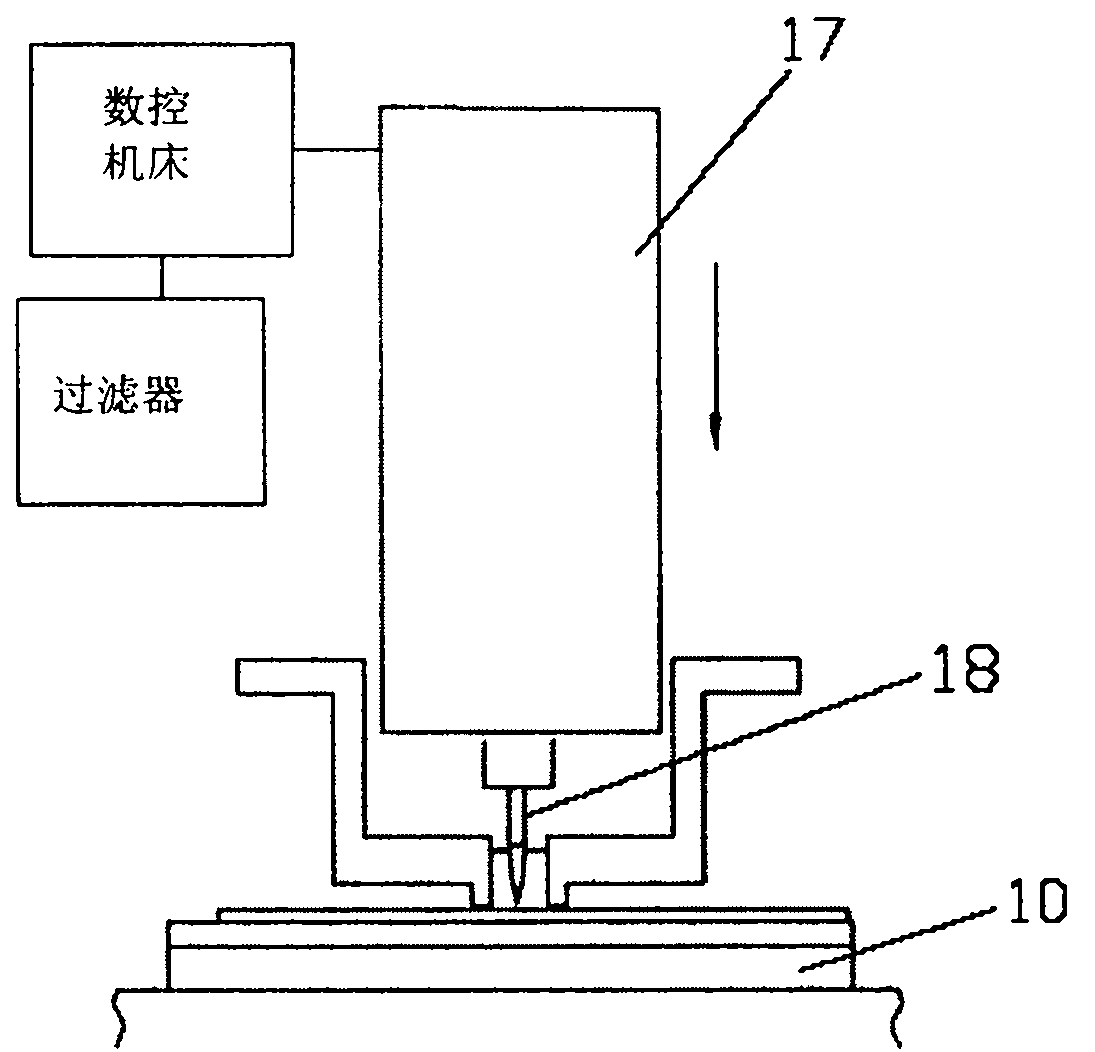

[0036] Please refer to Figure 5 , Figure 5 A flowchart showing the backdrilling method of the via hole of the present invention. The back drilling method comprises the following steps:

[0037] Step S01: using a drilling machine to measure the local thickness of the circuit board with the target through hole at the target through hole;

[0038] Step S02: automatically determine the back-drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com