Cableless electric connecting device

An electrical connection device and electrical connection technology, applied in the information field, can solve problems such as long process assembly cycle, error-prone, and complex, and achieve the effects of facilitating assembly, transfer and maintenance, improving assembly efficiency, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]Various details involved in the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

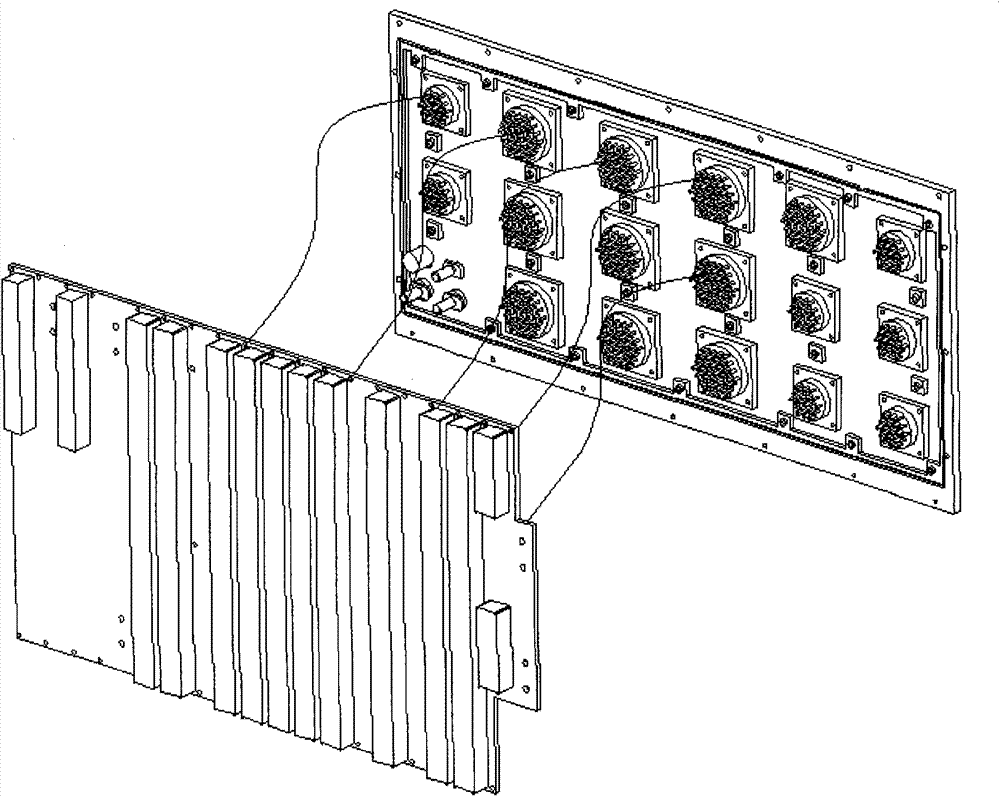

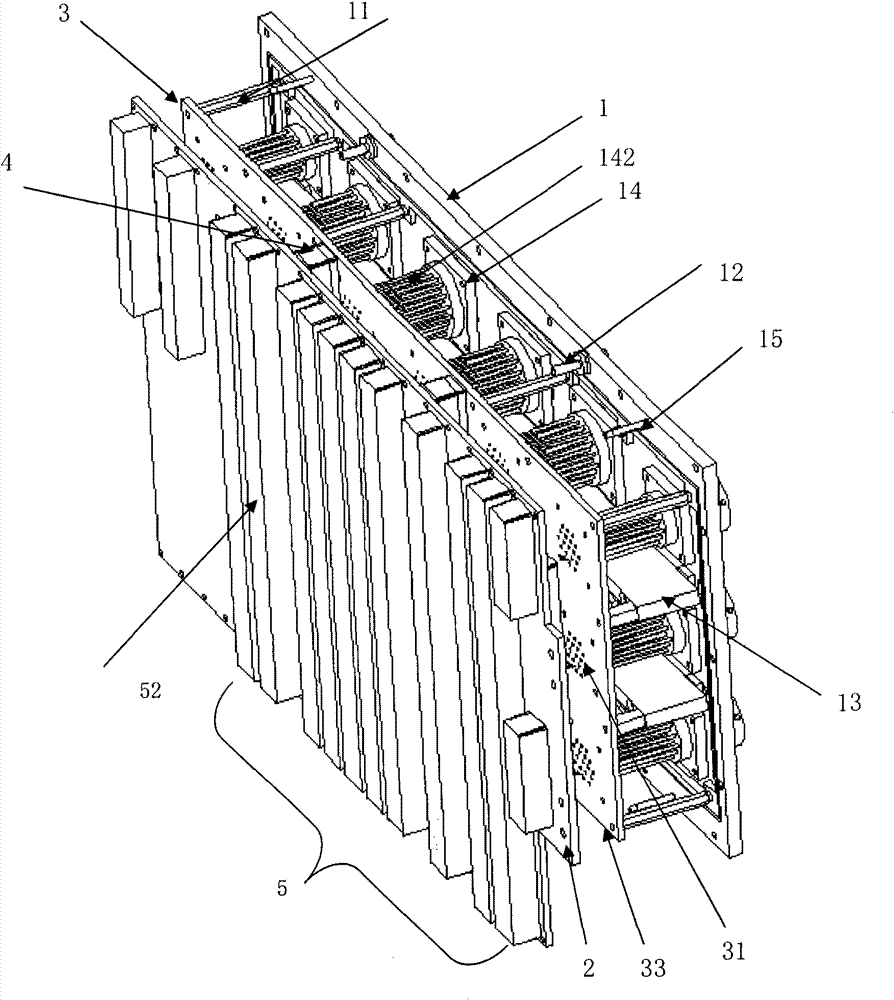

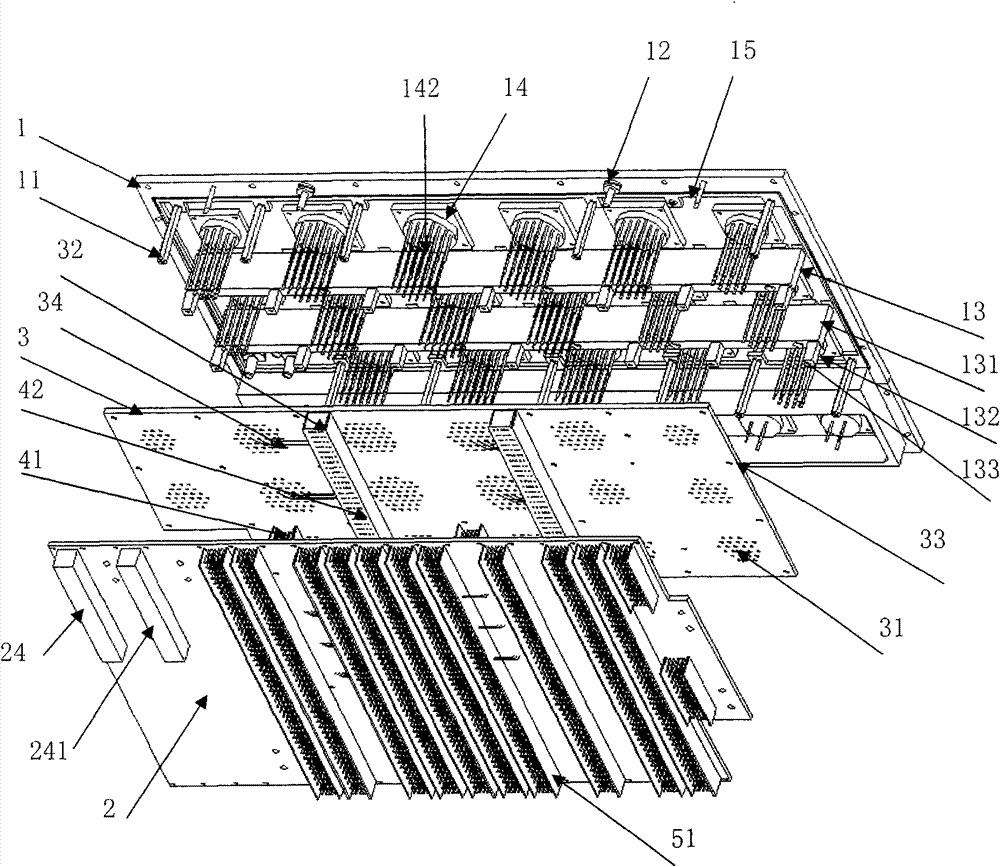

[0058] See figure 2 Schematic diagram of the structure of the cableless connection device of the present invention, which shows: aviation plug panel 1, backplane 2, aviation plug printed board 3, A connector 4 and B connector 5; see again image 3 Showing the laminated structure of the cableless connection device of the present invention, Figure 4 Shows the front view of the aviation plug panel 1 of the present invention, on which a plurality of pillars 11, a plurality of tops 12, a plurality of reinforcing ribs 13 and 131, a square platform 132, a threaded hole 133, a plurality of aviation plug boards are fixedly connected. Plug 14, positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com