Measuring method for rotate speed of turbine

A measurement method and steam turbine technology, applied in the direction of using a device for measuring the time required to move a certain distance, can solve problems such as inaccurate measurement, jump changes, errors, etc., achieve accurate measurement of rotational speed, eliminate calculation errors, and ensure measurement response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

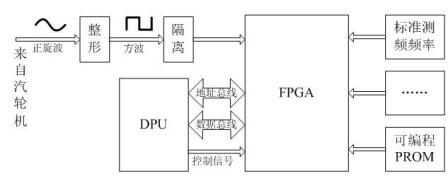

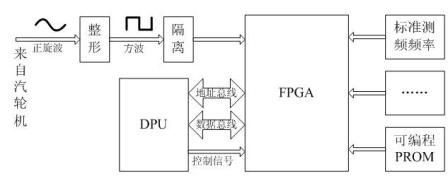

[0016] like figure 1 As shown in the system block diagram of the speed measurement module, the DPU (data processor) sets the number of steam turbine configuration teeth for the FPGA, and the rotation of the steam turbine gear generates a series of sine wave signals through the corresponding photoelectric pulse sensor and transmits them to the OPC module. The shaping circuit shapes the signal Become a square wave signal and transmit it to FPGA through high-speed optocoupler isolation. FPGA starts to fill and count the standard pulse output by the standard frequency at the first rising edge of the square wave, and stops counting after the number of rising edges of the configured tooth. Pass the filled pulse number to DPU, and calculate the steam turbine speed by DPU. This method is used to measure the speed of different steam turbines, especially the speed of the steam turbine with different spacing between the measurement gears. Since the speed of the steam turbine is calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com