Direct type evaporator capable of automatically returning oil

An evaporator, direct technology, applied in the direction of evaporator/condenser, refrigeration components, refrigerators, etc., can solve the problems of unstable oil return and poor oil return effect of the return air pipe, and achieve good oil return effect and stable oil return , The effect of facilitating the overall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

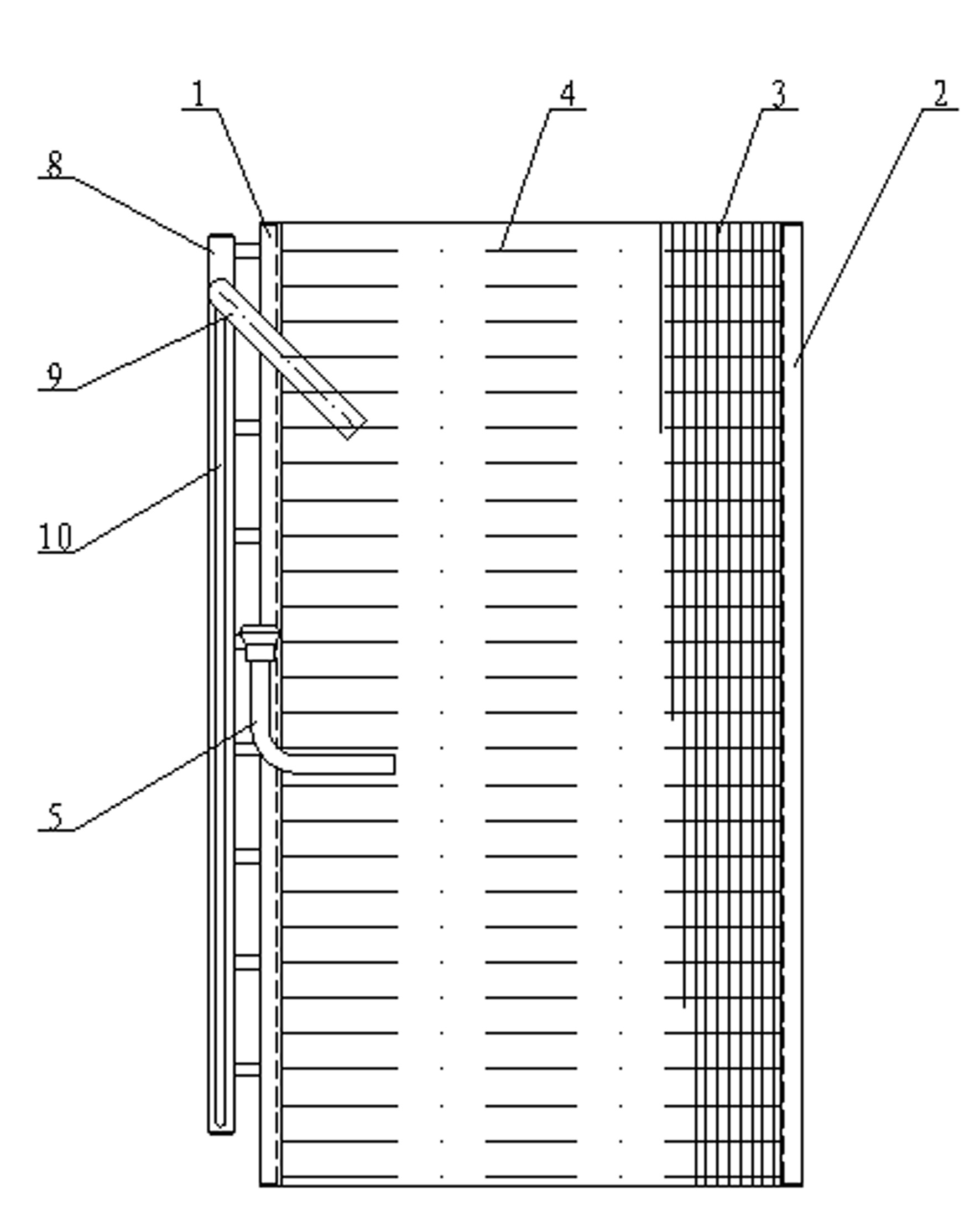

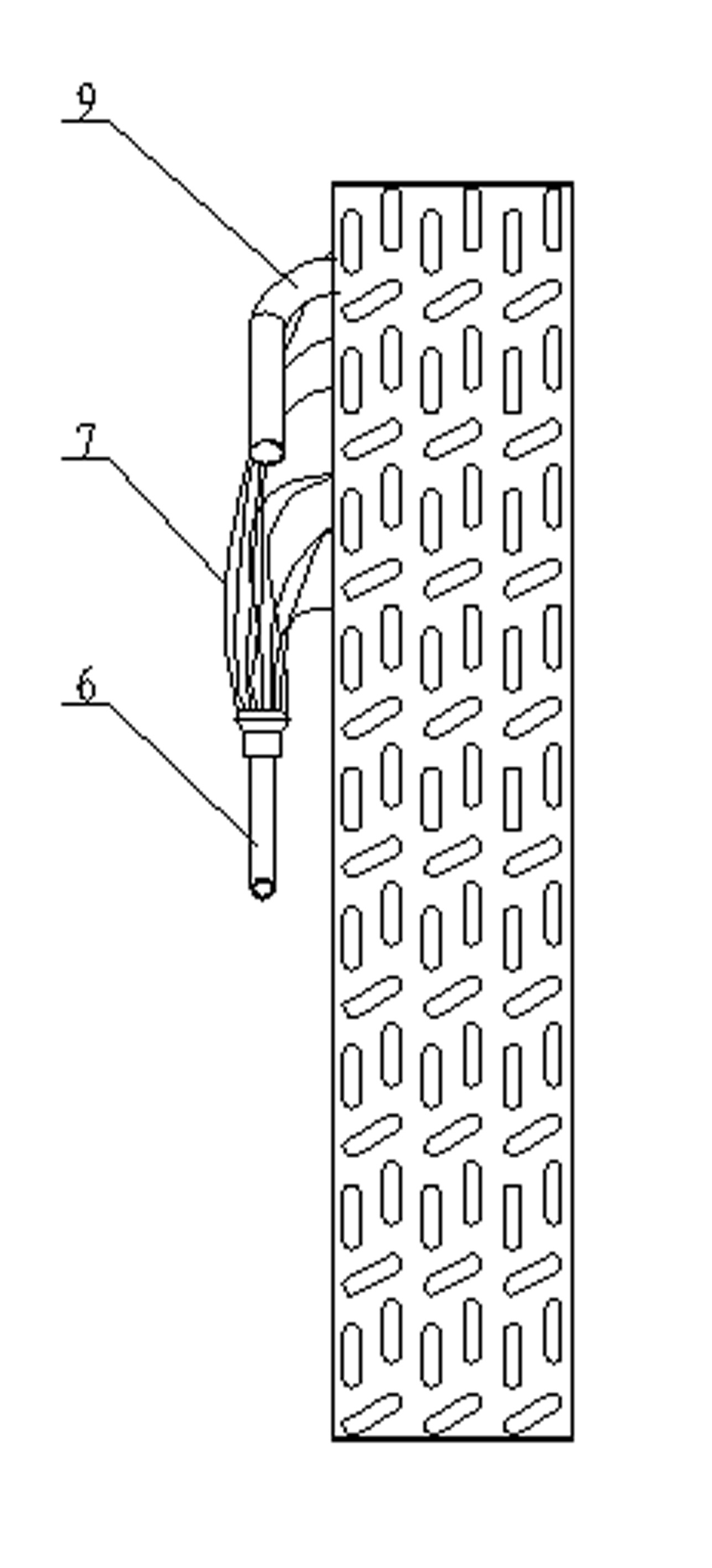

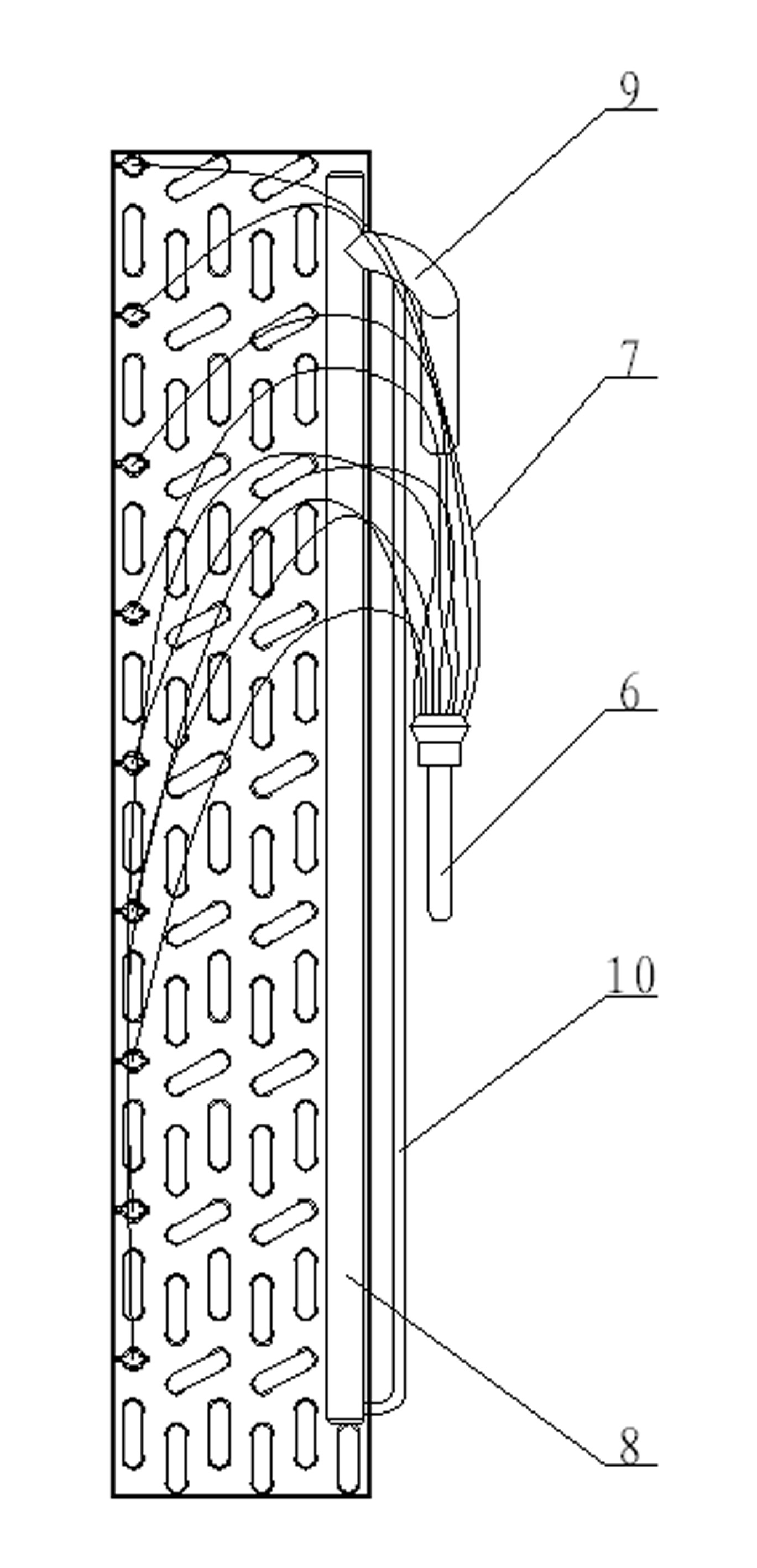

[0013] Figure 1-3 As shown, the direct evaporator with automatic oil return includes left tube plate 1, right tube plate 2, fin 3, evaporation tube 4, liquid inlet tube 5, liquid separator 6, capillary tube 7, gas collecting tube 8, and gas return tube 9 And oil return small standpipe 10. A plurality of evaporating tubes 4 pass through the left tube plate 1, multiple fins 3 and right tube plate 2 from top to bottom, and one end of the multiple evaporating tubes 4 is connected to the liquid inlet tube 5 of the evaporator via a plurality of capillary tubes 7 6. The other ends of the plurality of evaporator pipes 4 are connected to the gas collection pipe 8 vertically arranged in the middle and upper part of the evaporator. The top of the gas collection pipe 8 is provided with a return pipe 9 connected to the compressor, and the bottom port of the small oil return standp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com