Assembling structure on a light foam concrete unit

A technology for assembling structures and components, which is applied in the direction of building construction and construction, can solve the problems of weak tensile force, brittle surface strength of ALC components, etc., and achieve the effect of preventing brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] First, the configuration of the embodiment will be described.

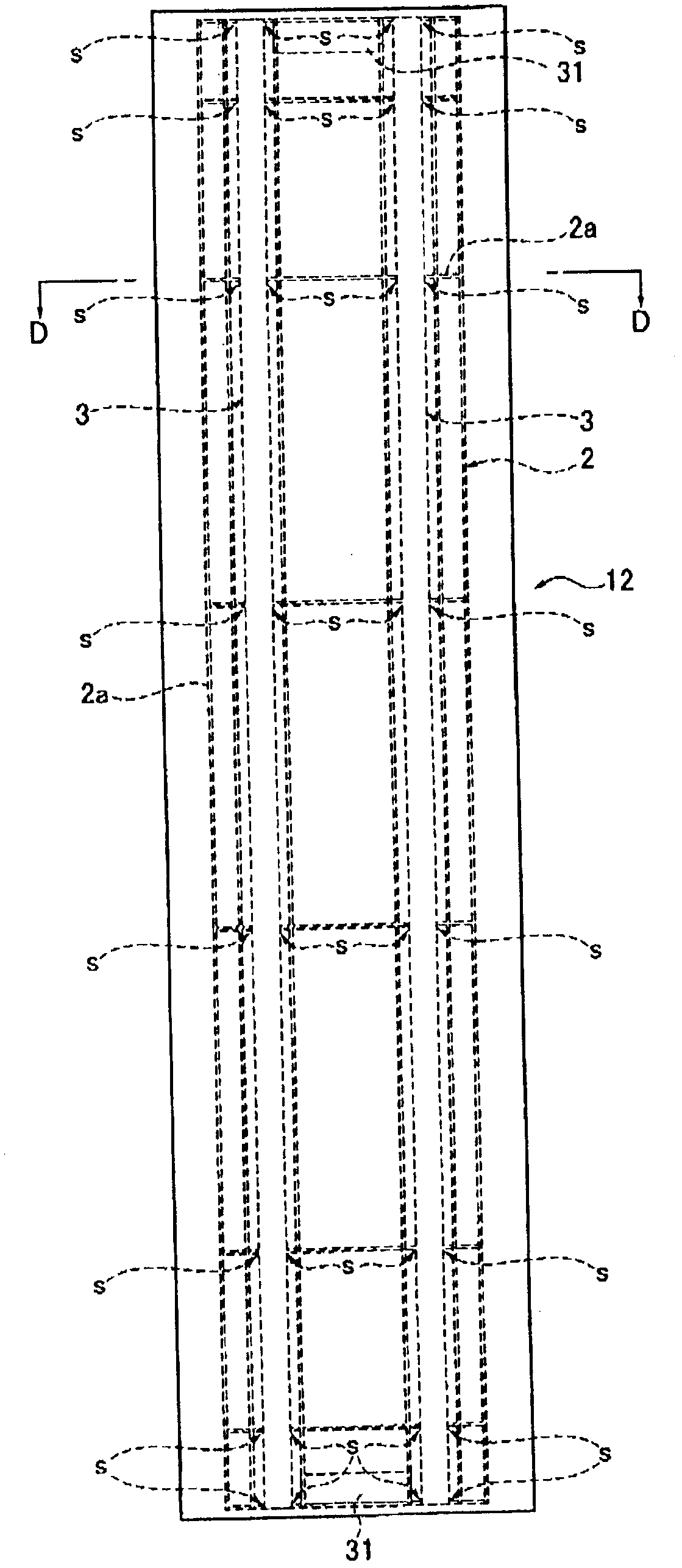

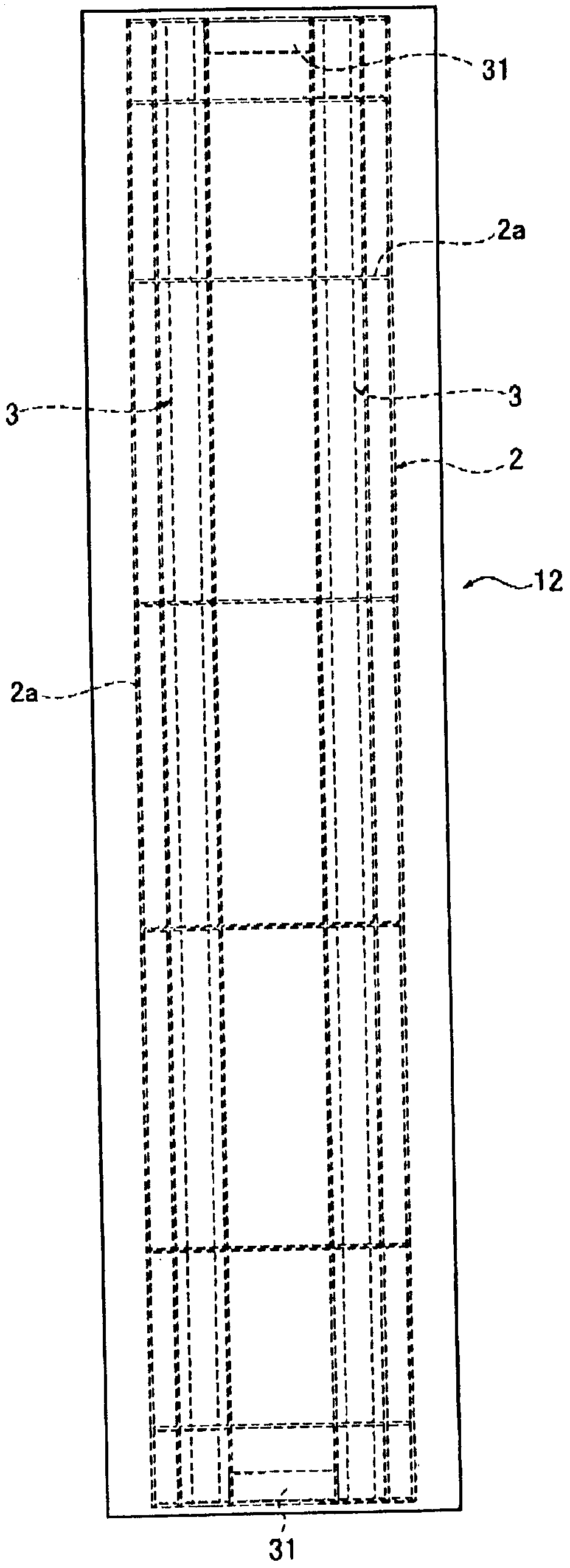

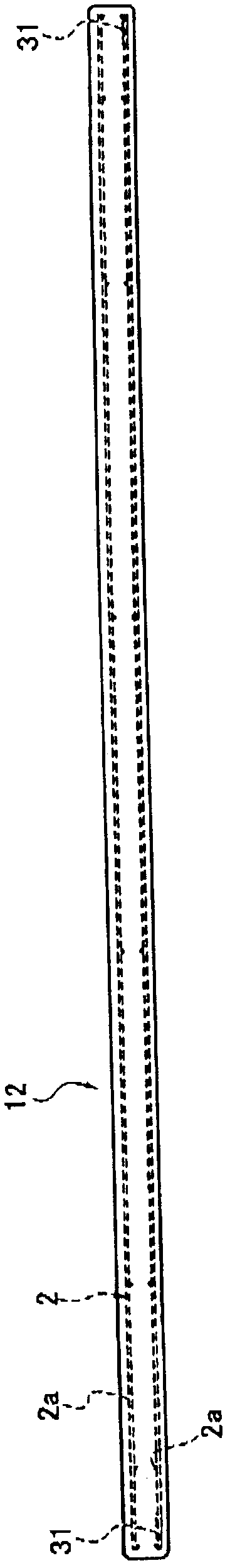

[0038] like Figure 1 to Figure 3 As shown, the ALC component of this embodiment is the outer wall panel 12 .

[0039] like figure 1 As shown, the outer wall panel 12 has the following structure: a steel frame 2, metal sheets 3, 3 and metal sheets 31, 31 fixed on the steel frame 2 are embedded in ALC (lightweight foamed concrete).

[0040] Here, as Figure 1 to Figure 3 As shown, on a reinforcing bar frame 2 composed of a plurality of reinforcing bars 2a, . . . by welding (spot welding) a pair of long metal pieces 3, 3 and the portion s in contact with the reinforcing bars 2a, . . . The pieces 3 and 3 are fixed substantially symmetrically on the left and right along the front center of the longitudinal direction of the reinforcing bar frame 2 .

[0041] In addition, the pair of short metal pieces 31 and 31 are welded (spot welding) to the contact portion s of the reinforcing bars 2a, . . . Fixed symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com