Method for enhancing quality of lignite by using saturated vapor

A technology for steam and lignite, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of restricting the use effect of lignite upgrading, the impact of application process, increasing processing and post-transportation costs, etc., to improve the reuse rate and performance. , the effect of improving energy efficiency

Active Publication Date: 2011-04-06

北京国丰创展科技发展有限责任公司

View PDF1 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method will also increase the cost of processing and post-transportation, and the small-sized upgraded lignite will seriously affect the application process, which limits the use effect of lignite upgrading

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

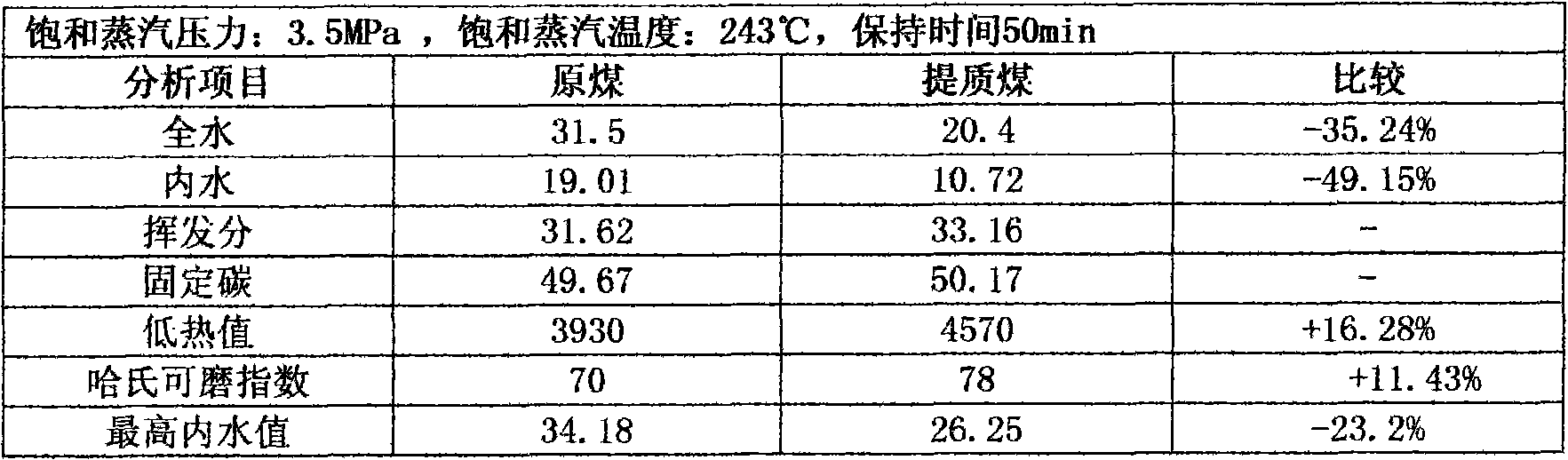

Embodiment 1

[0051]

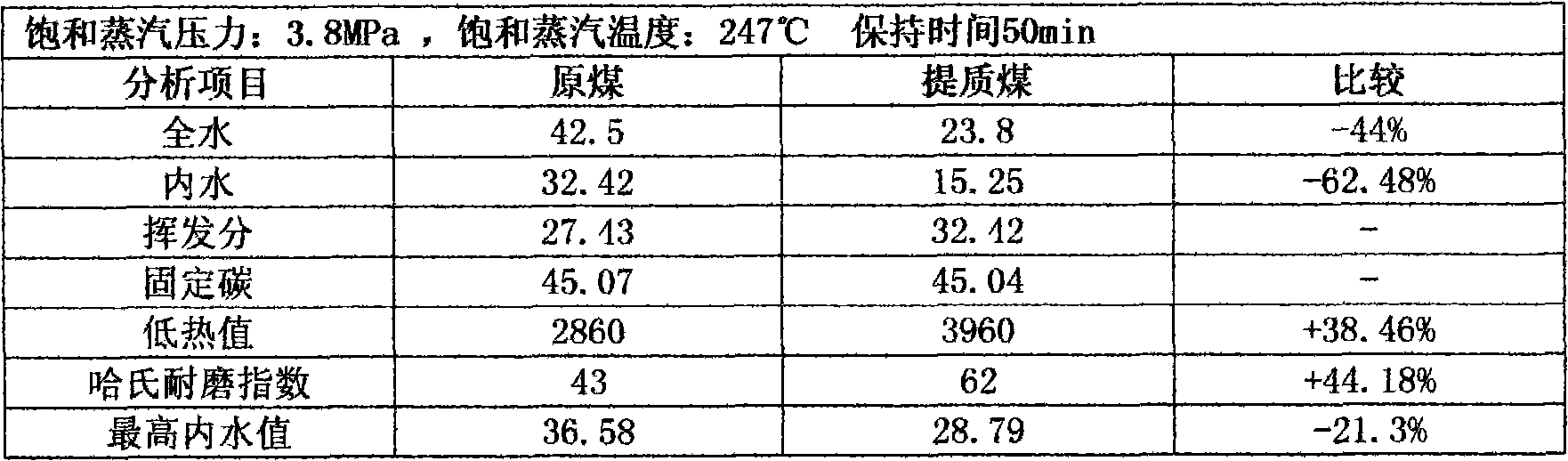

Embodiment 2

[0053]

Embodiment 3

[0055]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for enhancing quality of lignite by using saturated vapor. Screened lignite blocks are processed by quality enhancement by using saturated vapor, and pressure, temperature and holding time are utilized to achieve the goals of extruding water out of lignite, sealing the capillary bores of lignite and realizing the hydrophobicity of lignite; and meanwhile, wastewater, which is generated in the quality enhancement process and recycled after discharged vapor is condensed, is converted into steam to be supplemented to the saturated vapor, and the generated non-condensable gas is directly discharged after no-pollution treatment. Thus, the production cost in the quality enhancement process is greatly lowered, the energy utilization ratio is enhanced and the environmental pollution is reduced. The method has high safety and is convenient for operation, and virtuous cycle of the lignite quality enhancement process is truly realized; and the quality-enhanced lignite is simple and convenient for transportation and storage, and has wide applicability and wide market prospects.

Description

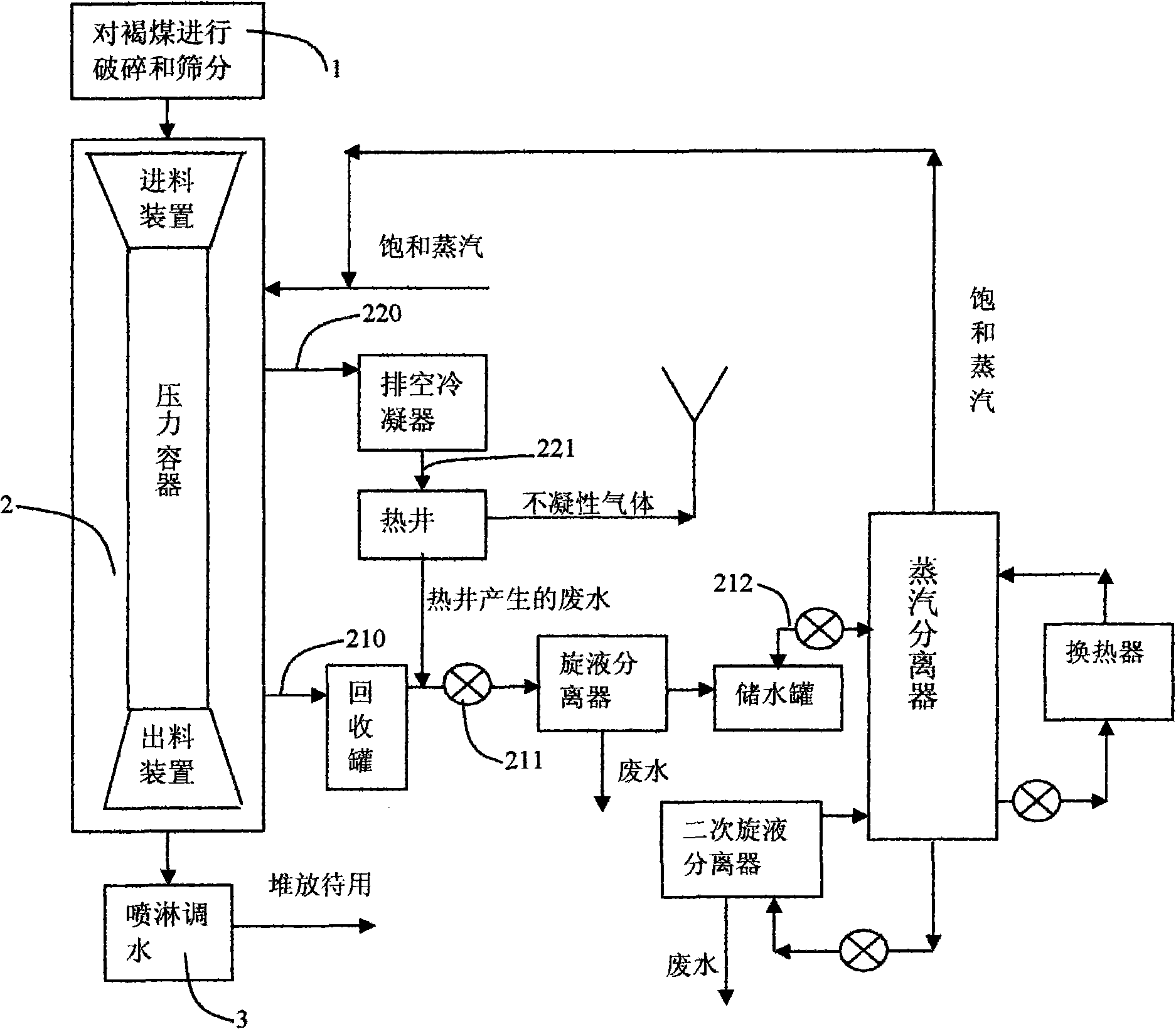

technical field [0001] The invention relates to a method for upgrading lignite, in particular to a method for upgrading lump lignite by using saturated steam with high safety and convenient operation, belonging to the field of coal processing. Background technique [0002] Lignite, also known as firewood coal, is a brown-black low-rank coal whose coalification degree is between peat and bituminous coal. It is the corrosion value of coal formed by diagenesis, with the lowest degree of coalification, brown, dark brown or black, generally dull or asphalt luster, and not cohesive. Its physical and chemical properties are between peat and bituminous coal. It has high water content, high volatile content, low density, contains humic acid, and often has an oxygen content of 15-30%. It is easily weathered and broken in the air, and has low calorific value. [0003] Lignite upgrading refers to the removal or partial removal of moisture and oxygen-containing functional groups in lig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L9/00

Inventor 杨新华

Owner 北京国丰创展科技发展有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com