Method for preparing emulsion explosive

An emulsion explosive and a manufacturing method technology, which is applied to explosives and other directions, can solve the problems of low charging efficiency, poor blasting effect, high labor intensity, etc., and achieve the effects of high flammable gas safety, high charging efficiency and good blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

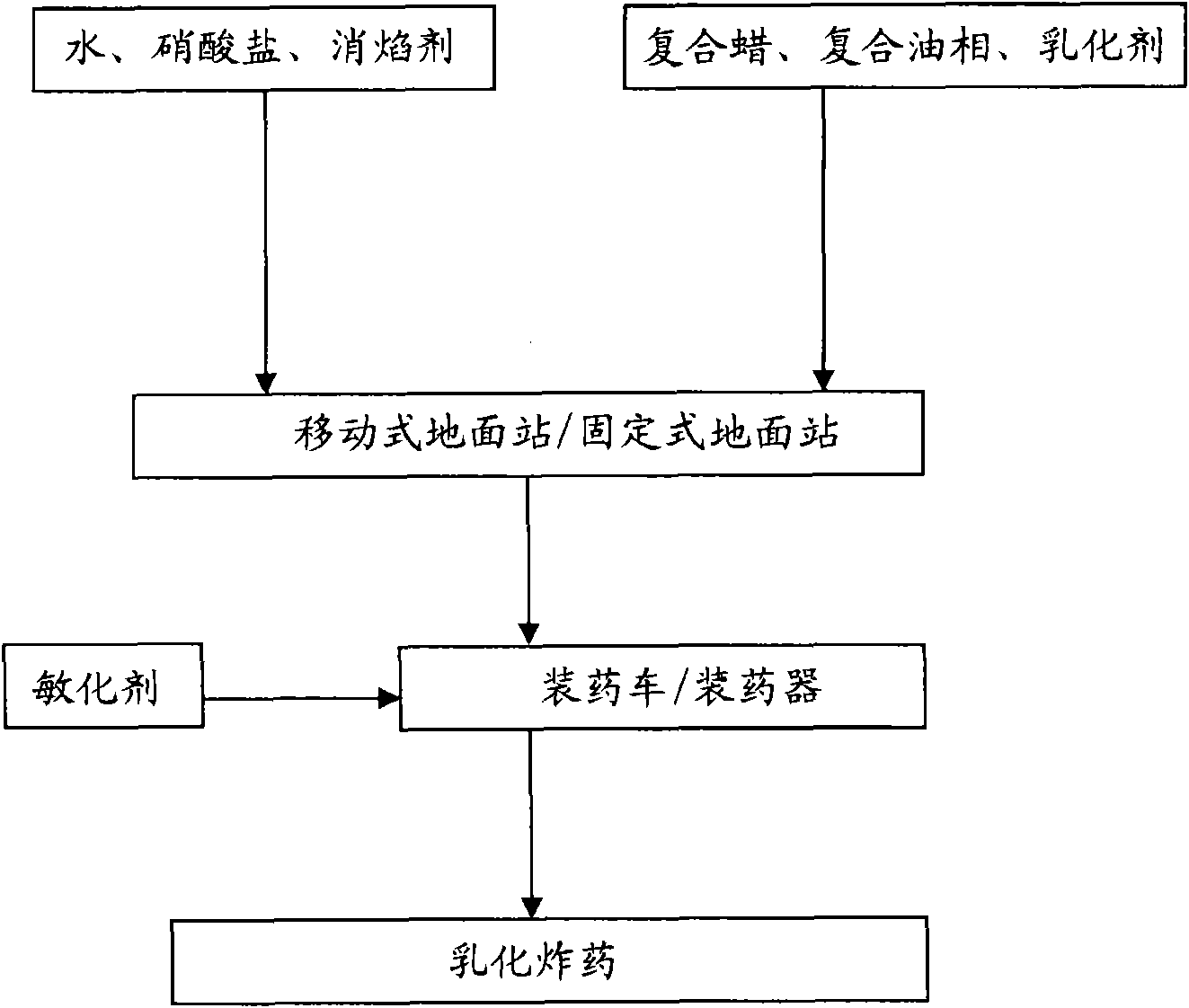

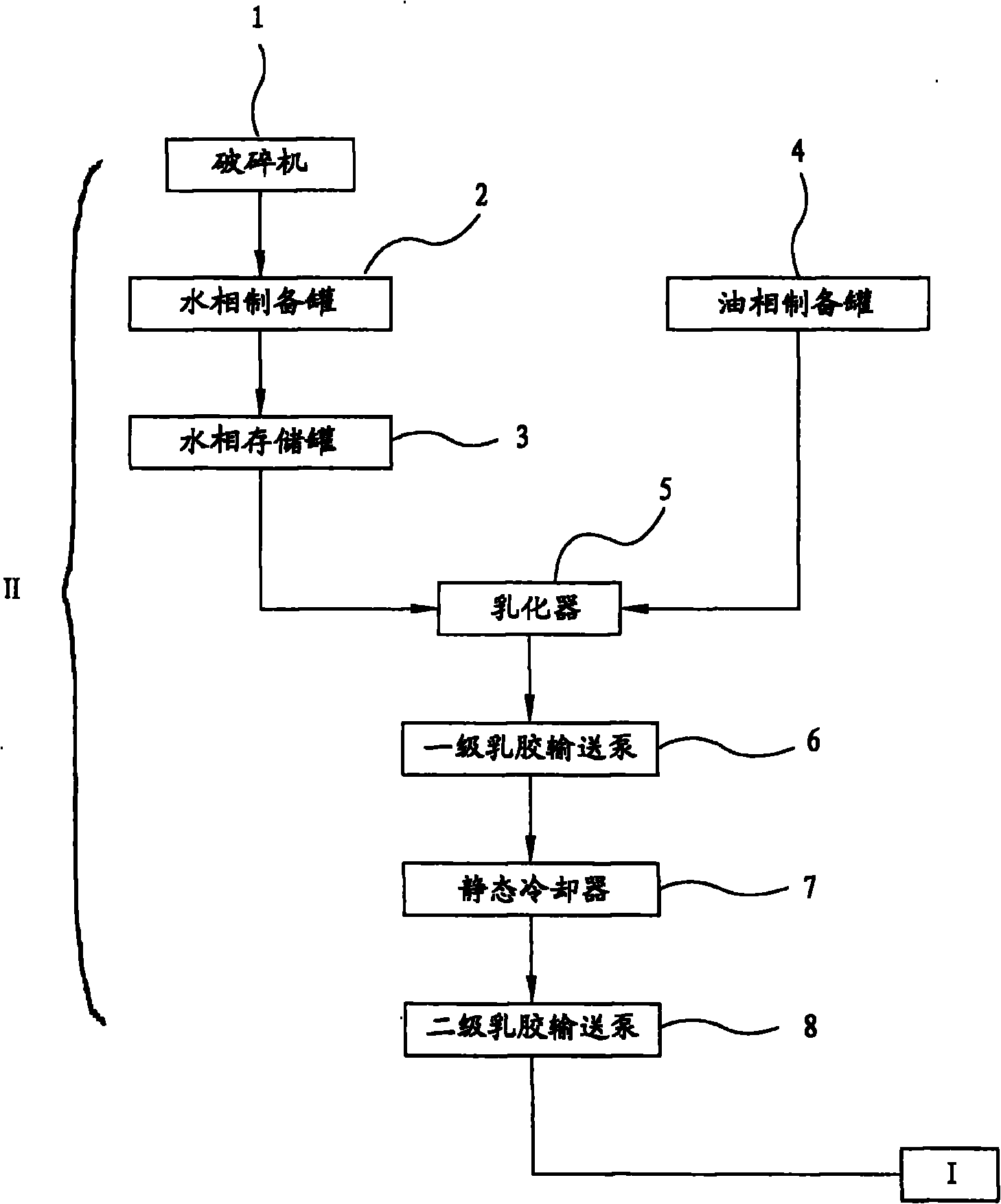

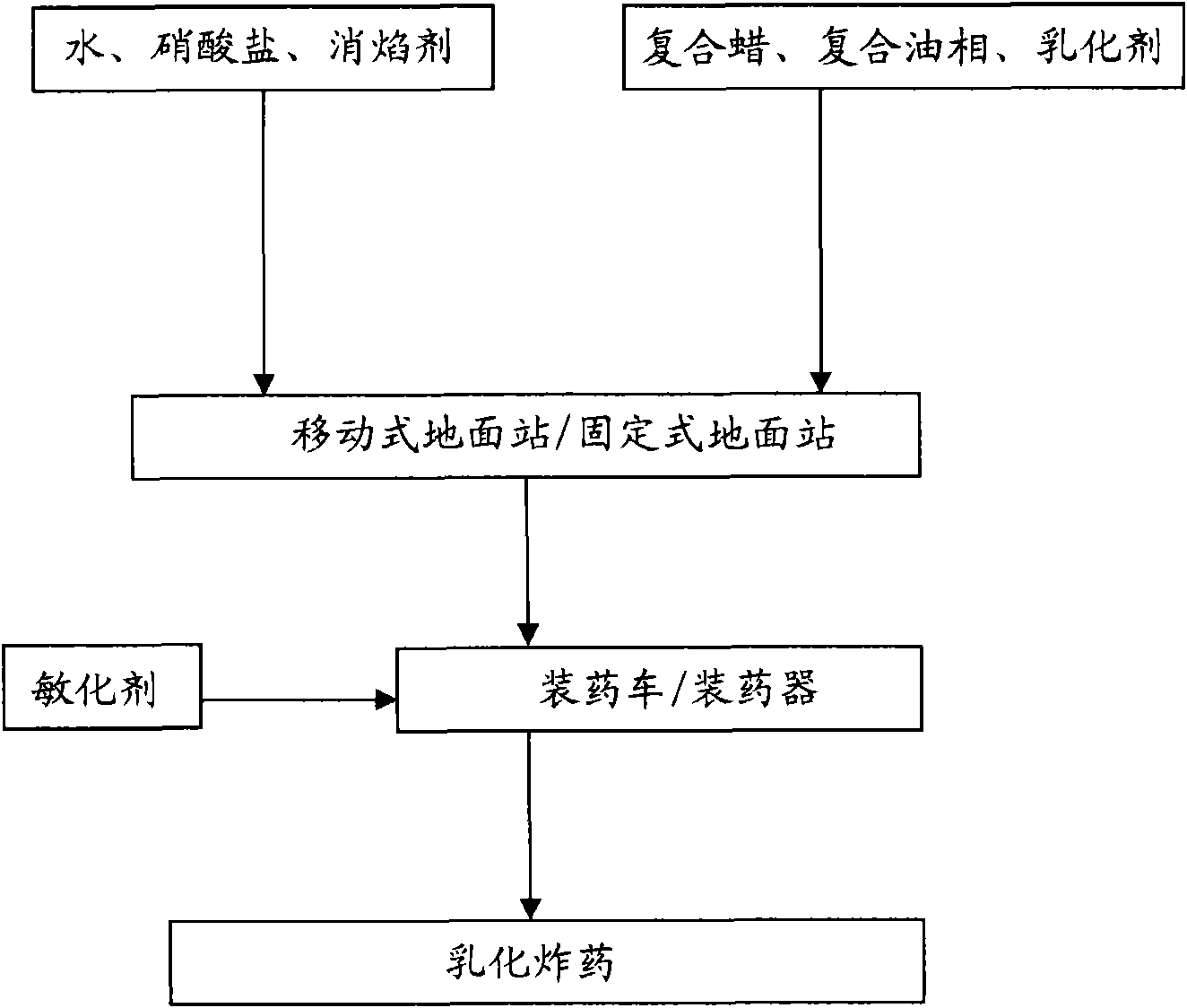

[0035] The finished emulsion explosive is formed by sensitization and foaming of the latex matrix under the action of a sensitizer. Therefore, the production of the emulsion explosive must first prepare the latex matrix.

[0036] The latex matrix of emulsion explosives contains a water phase material and an oil phase material. The water phase material may contain a mixture of ammonium nitrate, sodium nitrate and water, and the oil phase material may contain emulsifiers, mineral oil and complex waxes. Mineral oil may contain one or more of diesel oil, engine oil, and the like. Compound wax can be a mixture of ozokerite and paraffin. It should be understood that the water and oil phase materials are not limited to the listed materials.

[0037] In addition, the latex matrix also contains a certain amount of additives as foam accelerators. Generally speaking, the additives are acidic substances, such as citric acid.

[0038] Commonly used emulsifiers are SPan-80 or polyisobuty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com