Conveying device

一种输送装置、输送链的技术,应用在输送机、运输和包装等方向,能够解决链条与链轮不能很好的啮合、加大偏差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

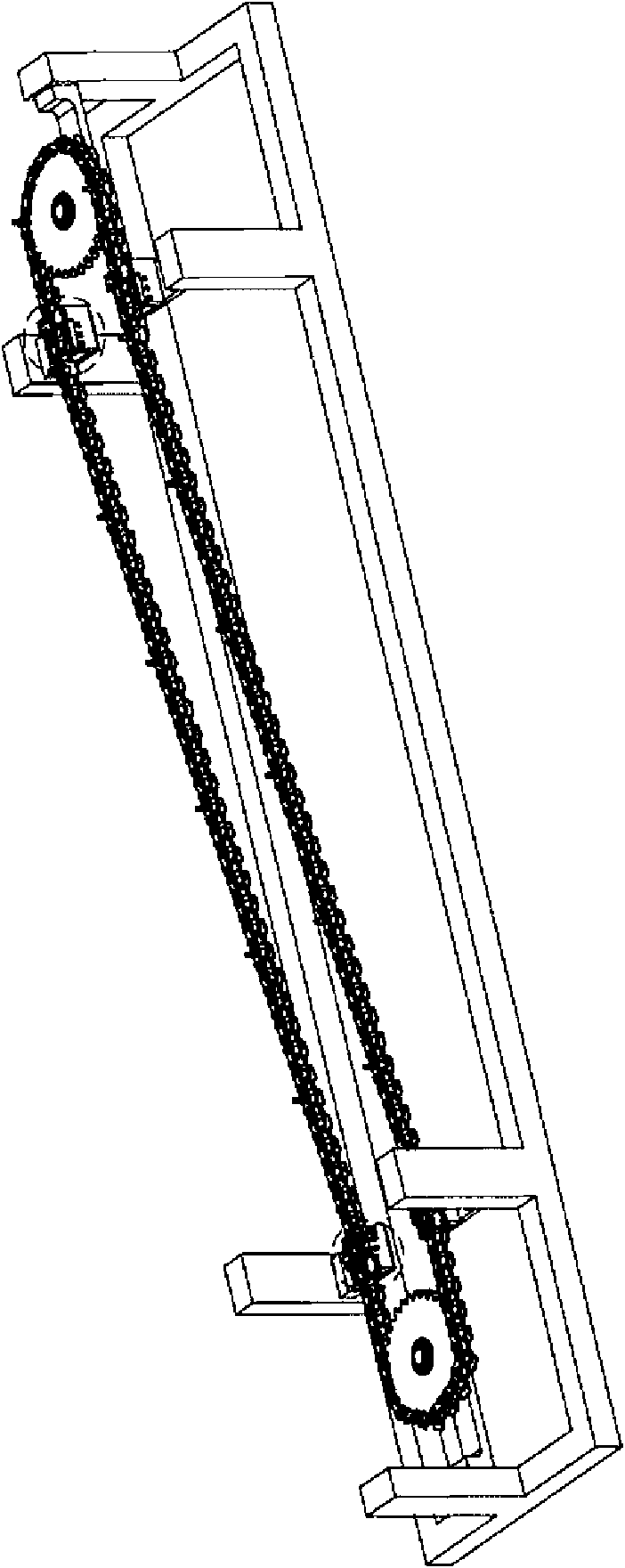

[0015] see figure 1 A preferred embodiment of the delivery device of the present invention is shown. The conveying device 100 includes a conveying chain 10 , an adjusting mechanism 50 , a bracket 41 and two sprockets 43 . The bracket 41 is used to fix the sprocket 43 and the adjustment mechanism 50 . The adjustment mechanism 50 includes a plurality of flattening components 20 and a plurality of flattening components 30 for ensuring smooth engagement of the conveyor chain 10 with the sprocket 43 . In this embodiment, there are two flattening assemblies 20 and two flattening assemblies 30 .

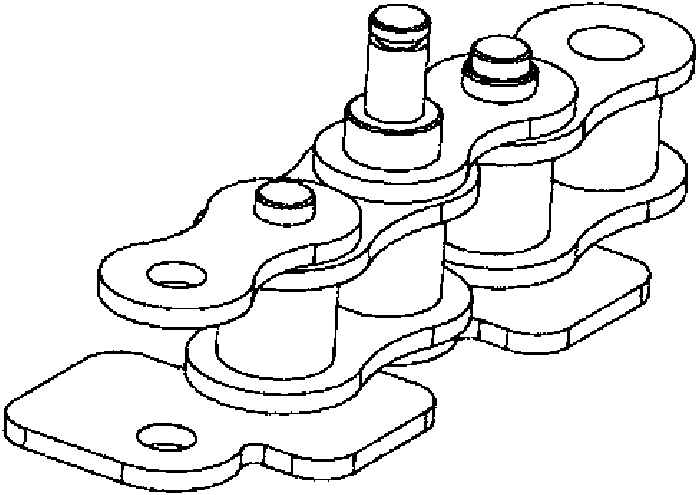

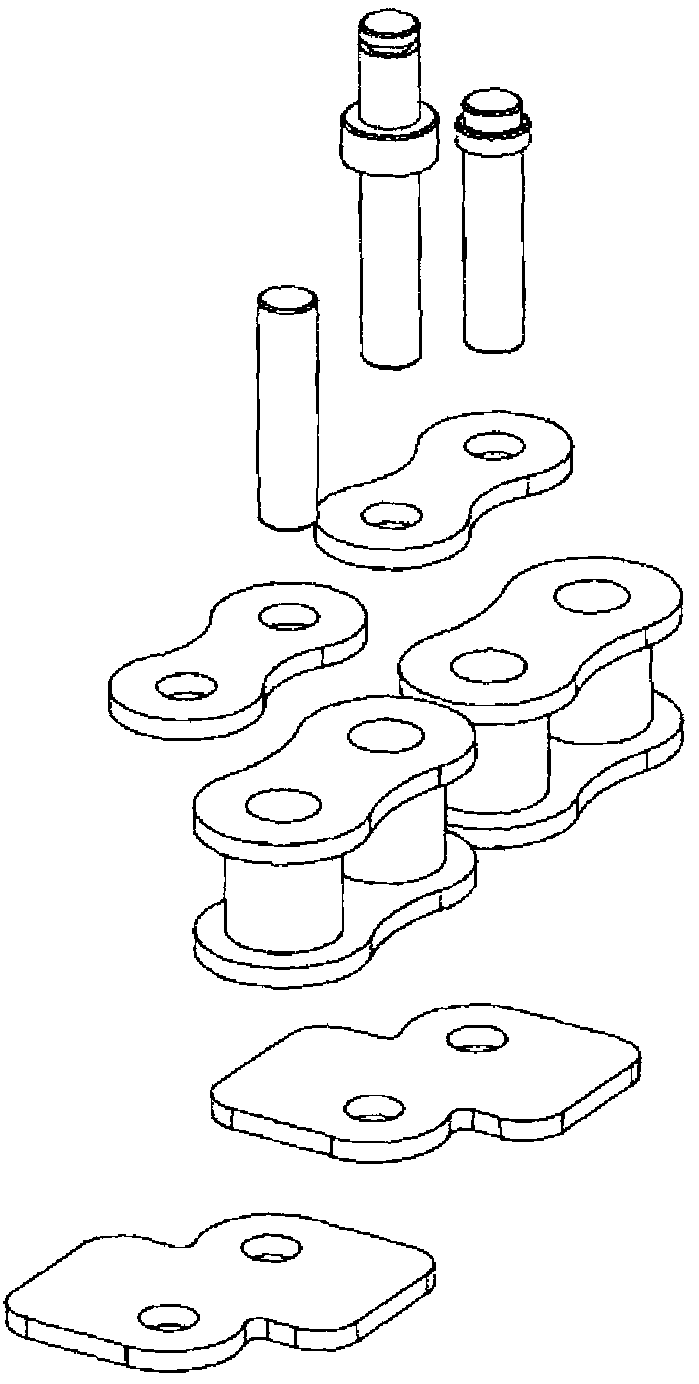

[0016] see figure 2 and image 3 , the conveying chain 10 includes several linking units 11 and several connecting components 12 . Every two link units 11 are connected through a connecting component 12 .

[0017] Each link unit 11 includes two link plates 111 and two link posts 112 . The two chain plates 111 are arranged in parallel. The two chain posts 112 are spaced between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com