Floating tapping clamp for automotive connecting rods

A technology of automotive connecting rods and wire clamps, applied in clamping, manufacturing tools, supports, etc., to achieve the effects of novel structural design, high tapping efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

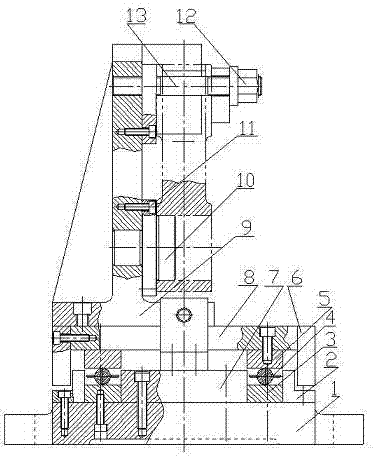

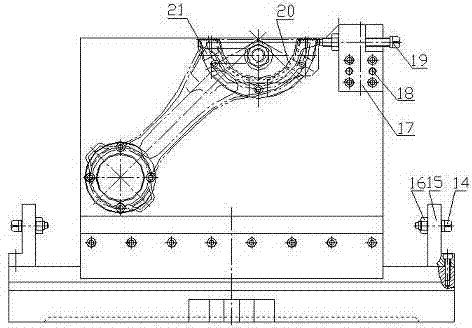

[0009] Example 1: refer to the attached figure 1 and 2 . An automobile connecting rod floating tapping fixture, which comprises a base 1, a cushion block 7 on the base is located on the base 1, a steel ball lower support plate 3 is sleeved on the base 1 and forms a boss structure with the base cushion block 7, and the steel ball And the spring clip 4 is located on the boss, its upper side is provided with a small triangle iron bar 2, the upper part is provided with a steel ball upper support plate 5, the upper support plate 8 is located on the steel ball upper support plate 5 and consists of the small triangle iron bar 2, steel The upper support plate 5 of the ball, the side part formed by the superposition of the upper support plate 8 is provided with baffles 6 on both sides, the triangle iron clamp body 9 is fixed on the upper support plate 8, the positioning pile head 10 is connected with the triangle iron clamp body 9, and the clamp double-ended stud 13 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com