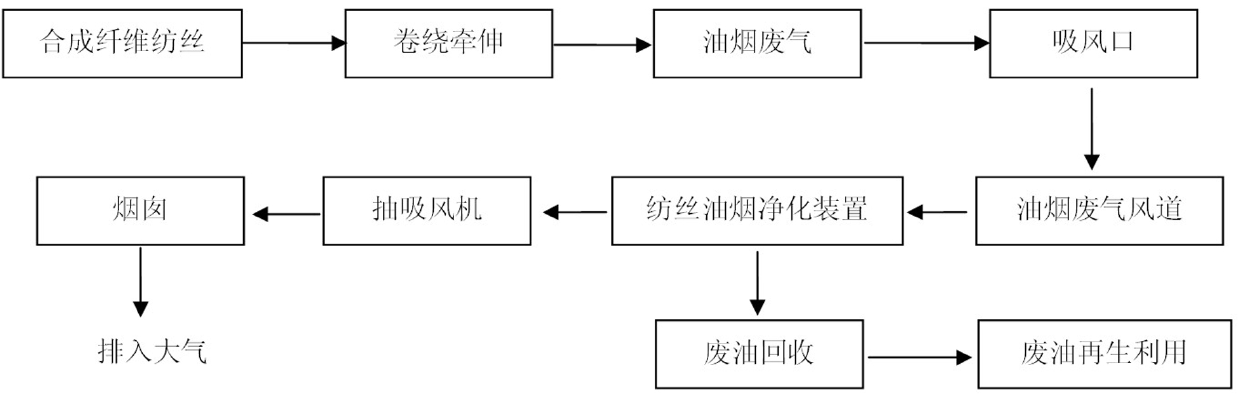

Spinning oil fume purifying device

A technology for oil fume purification and spinning, applied in the field of synthetic fibers, can solve the problems of prone to condensation, large temperature drop, unable to completely solve the problem of spinning oil fume treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 As shown, the spinning oil fume purification device includes a housing 18, and a plurality of anode tubes 11 (forming an anode column tube) are vertically arranged in the housing 18, and a cathode wire (corona wire) 12 hangs from the center of each anode tube 11 , the upper part of each anode tube 11 is inserted on the upper flower plate 10, the lower part of each anode tube 11 is inserted on the lower flower plate 20, the outer wall of the upper flower plate 10, the lower flower plate 20, the outer wall of the anode tube 11 and the inner wall of the housing 18 It forms a closed cavity, the upper part of the cavity communicates with the heat tracing steam inlet 19 provided on the side wall of the housing 18, and the lower part of the cavity communicates with the heat tracing condensate outlet 21 provided on the side wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com