Full-automatic tea processing method and equipment

A fully automatic, tea technology, applied in the direction of tea processing before extraction, can solve the problems of incapable technological innovation, backward automation assembly line control, high labor intensity, etc., achieve strong fault self-diagnosis ability, improve tea product quality, and improve intelligence. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail through examples below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

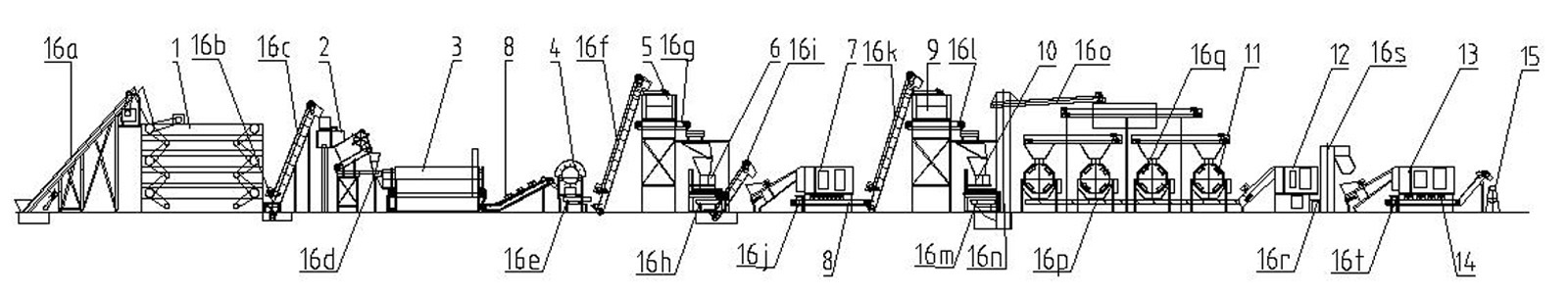

[0019] Such as figure 1 As shown, the full-automatic tea processing equipment of the present invention consists of fresh leaf greening equipment 1, fresh leaf flowmeter 2, cylinder type greening machine 3, air separation machine 4, fixed metering device 5, kneading machine 6, dryer 7, cooling Conveyor 8, fixed metering device 9, automatic kneading machine 10, frying and drying machine 11, flip-type cooling and regaining equipment 12, flip-type dryer 13, cooling conveyor 14, automatic bagging and packaging equipment 15, conveying equipment 16 And the corresponding PLC control system, industrial control host computer, etc., and each device is connected through the corresponding conveying device 16. The equipment is equipped with a PLC controller, and an independent control cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com