Method for storing fresh meat by combining decompression method with antistaling agent

A preservative and fresh meat technology, which is applied in the direction of chemical preservation of meat/fish, food preservation, meat/fish preservation, etc. It can solve the problems of reduced oxygen content, water reduction, and hindering the growth and development of microorganisms to achieve freshness The effect of prolonged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] storage:

[0043] 1. Freeze fresh meat that has passed quarantine at -20~-30℃ for 1 hour;

[0044] 2. Transfer the frozen fresh meat to 0~4℃ and cool it for 5~6 hours. After the core temperature drops to 0~4℃, cut the meat to remove the fascia and divide it into each piece. Small pieces weighing about 25~250g;

[0045] 3. Soak the meat in the preservative solution for 5 minutes. The composition of the preservative is: ε-polylysine 0.01% + chitosan 0.8% + sodium diacetate 0.30% + EDTA 0.01%. The balance is water;

[0046] 4. After taking it out, drain the water and put it in a pressure reducing device for storage. Store under the conditions of pressure conditions of -0.03 to -0.05 MPa, and air humidity of 95% or more.

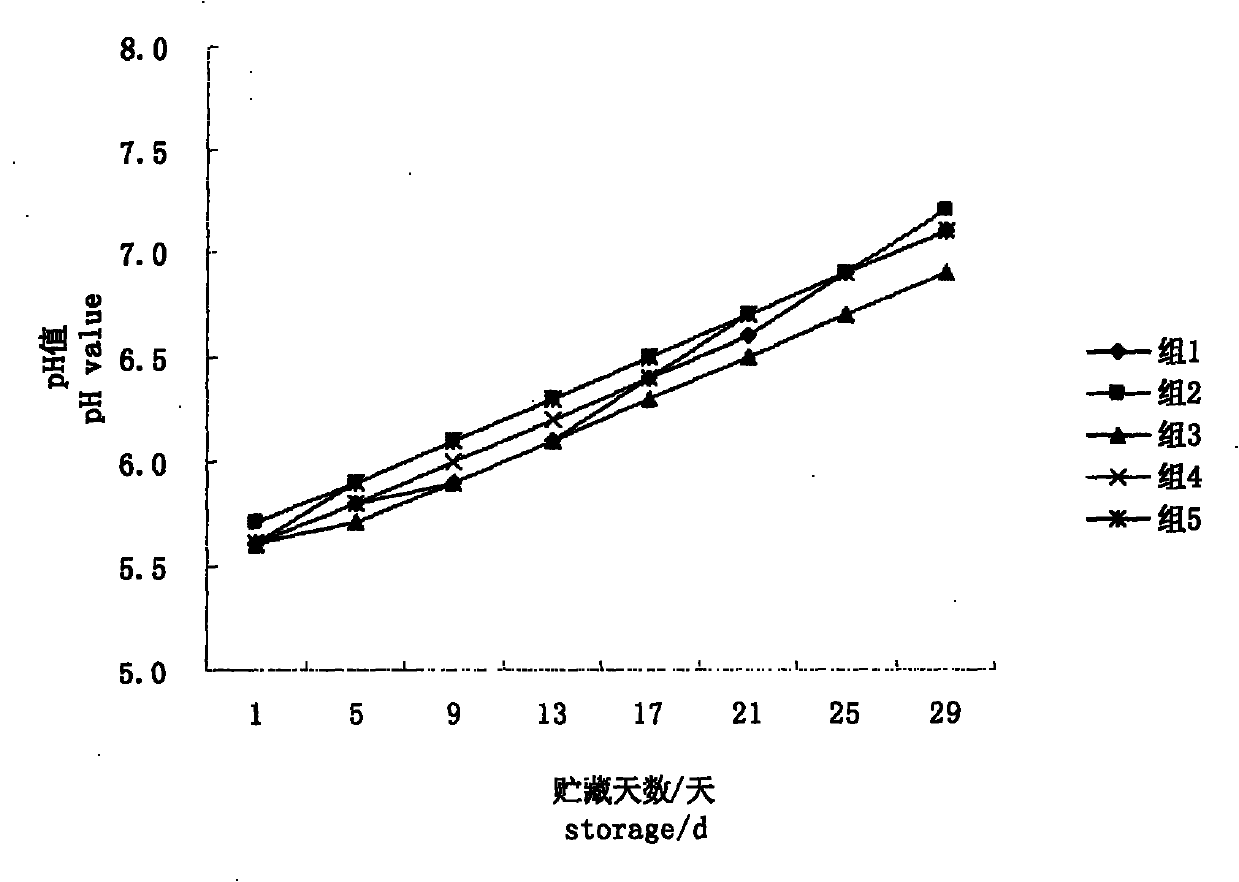

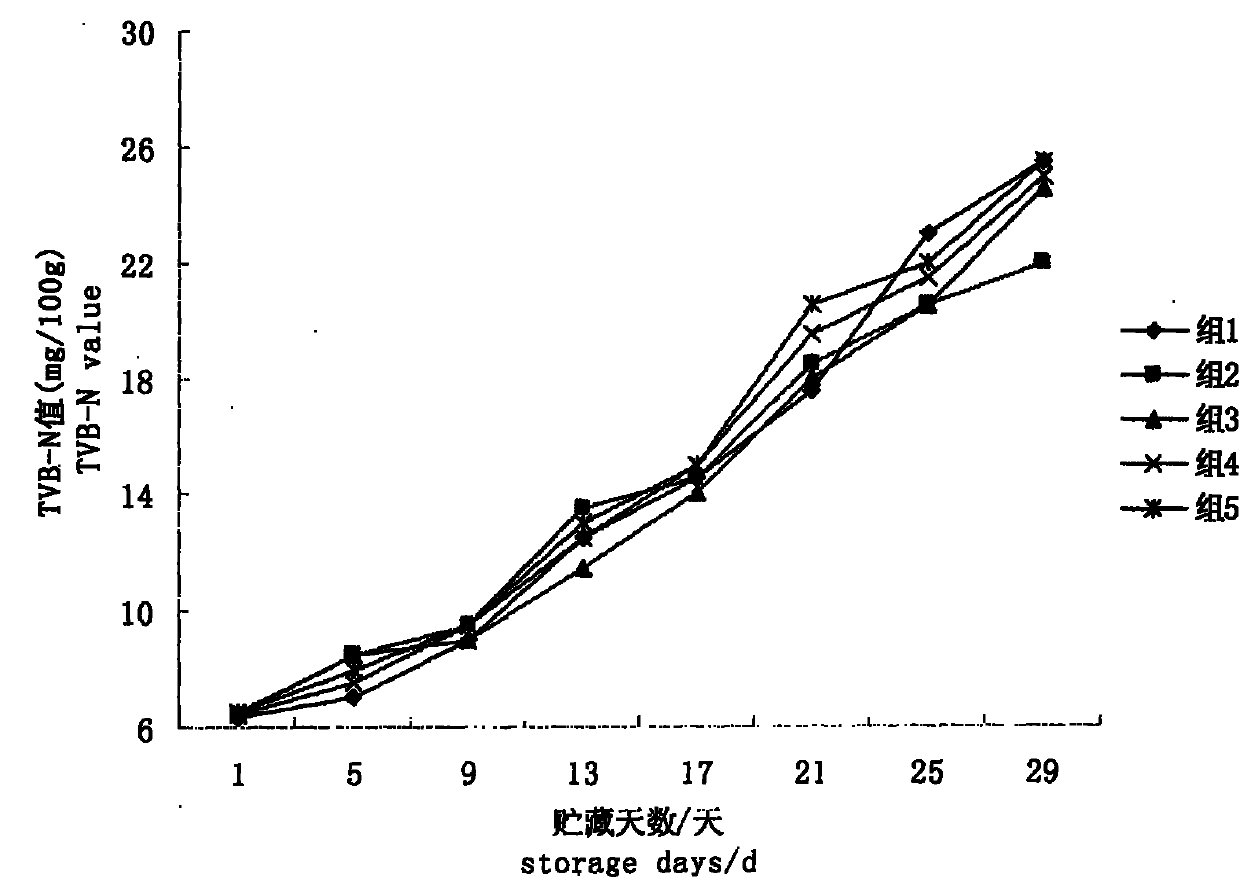

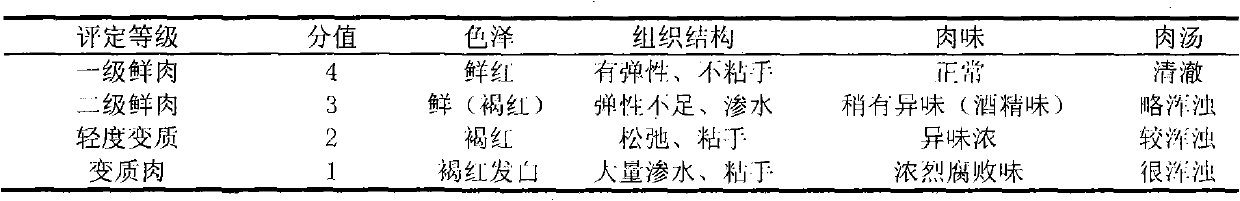

[0047] There is still a good evaluation score 17 days ago, the lowest score is only 3.0, which is still in the range of fresh meat, and the color of the meat is maintained during the storage process. This shows that the composite storage method is useful for ex...

Embodiment 2

[0050] storage:

[0051] 1. Freeze fresh meat that has passed quarantine at -20~-30℃ for 1 hour;

[0052] 2. Transfer the frozen fresh meat to 0~4℃ and cool it for 5~6 hours. After the core temperature drops to 0~4℃, cut the meat to remove the fascia and divide it into each piece. Small pieces weighing about 25~250g;

[0053] 3. Soak the meat in the preservative solution for 5 minutes. The antistaling agent is composed of 0.01% ε-polylysine + 0.8% chitosan + 0.30% sodium diacetate + 0.01% EDTA by weight percentage, and the balance is water.

[0054] 4. After taking it out, drain the water and put it in a pressure reducing device for storage. Store under the conditions of pressure conditions of -0.05 to -0.07MPa and air humidity of 95% or more.

[0055] The results showed that the scores were all out of 4 before the 9th day, and there were still good evaluation scores before the 13th day, the lowest score was only 3.0, which was still in the range of fresh meat, and the color of the ...

Embodiment 3

[0058] storage:

[0059] 1. Freeze fresh meat that has passed quarantine at -20~-30℃ for 1 hour;

[0060] 2. Transfer the frozen fresh meat to 0~4℃ and cool it for 5~6 hours. After the core temperature drops to 0~4℃, cut the meat to remove the fascia and divide it into each piece. Small pieces weighing about 25~250g;

[0061] 3. Soak the meat in the preservative solution for 5 minutes. The antistaling agent is composed of 0.01% ε-polylysine + 0.8% chitosan + 0.30% sodium diacetate + 0.01% EDTA by weight percentage, and the balance is water.

[0062] 4. After taking it out, drain the water and put it in a pressure reducing device for storage. Stored under the conditions of pressure conditions of -0.01 to -0.03MPa, and air humidity of 95% or more.

[0063] The results showed that the scores were all out of 4 before the 9th day, and there were still good evaluation scores before the 17th day, with the lowest score being only 3.0, which was still in the range of fresh meat, and the colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com