Jointed spearhead assembly

A connected and spearhead technology, applied in the field of spearhead assembly, can solve problems such as deformation, tripping, failure, and weakness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

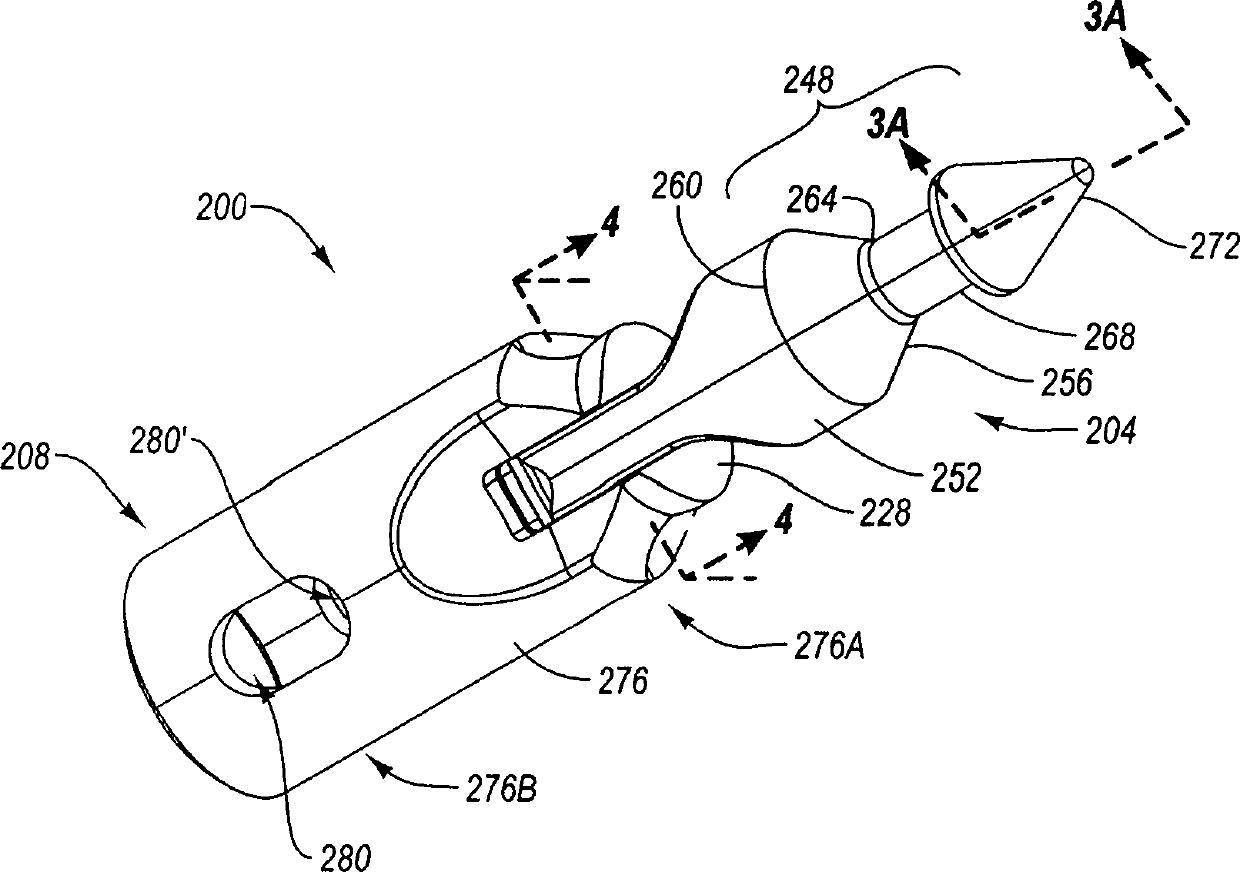

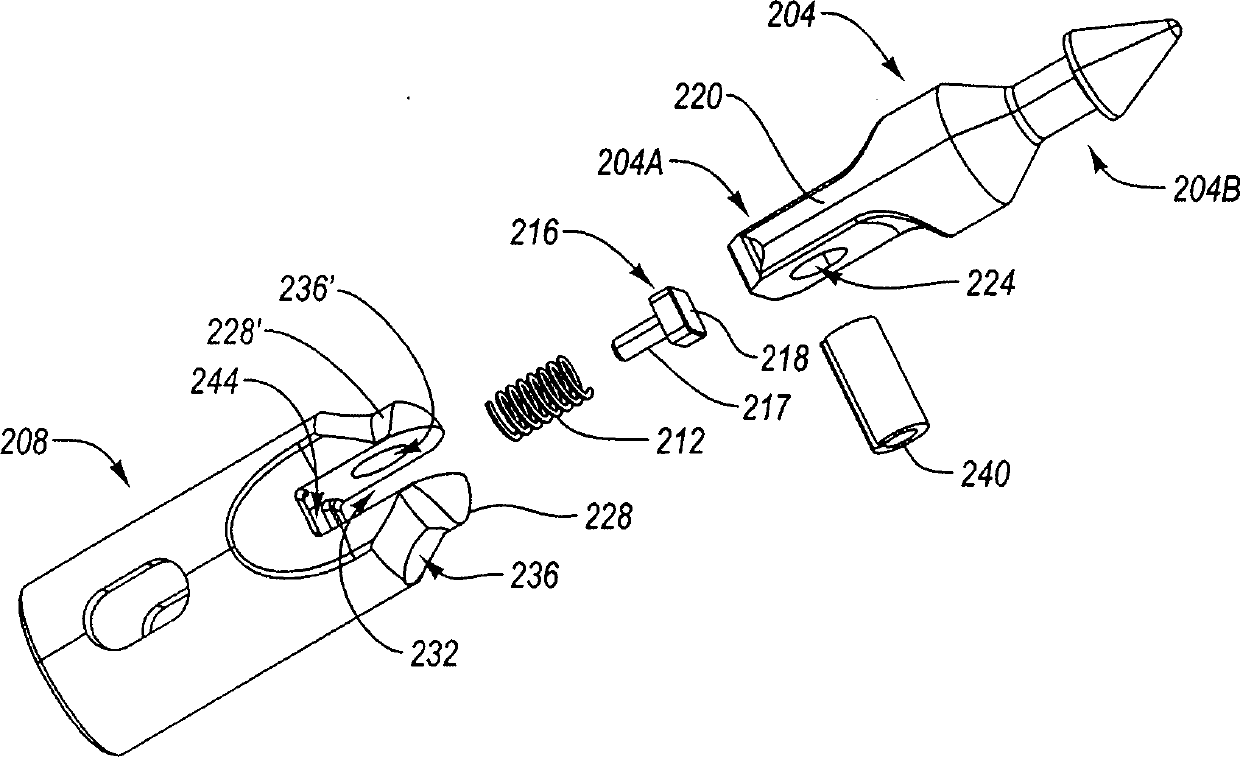

[0021] Herein, a spearhead assembly, method and system are provided. The spearhead assembly includes a spearhead and a base. The spearhead may have a follower tab having a non-convex first surface. A follower and biasing element are connected to the base so as to be located at least partially within the base.

[0022] Such a configuration may allow the spearhead assembly to be rotatably connected to help transfer mechanical stress and strain from the weakest point to an area of greater strength and durability. Furthermore, since the loading element can be placed in a recess in the base, safety is increased since the operator cannot be caught or otherwise injured by the exposed spring of the loading element. Additionally, the loading element may be located on the outside of the follower, inside the base, as opposed to inside the follower tab. Such a configuration may allow the loading element to be larger and stronger than conventional springs.

[0023] In addition, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com