Air conditioning system combined by indirect evaporation chiller plant and traditional mechanical refrigerating unit

A technology of evaporative cold water and air-conditioning system, which is applied in the field of air-conditioning system combined with indirect evaporative water chiller and traditional mechanical refrigeration unit, to achieve the effect of reducing power load, high efficiency of energy utilization, and realizing energy-saving regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

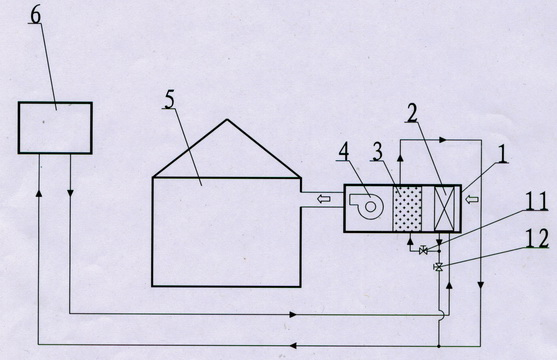

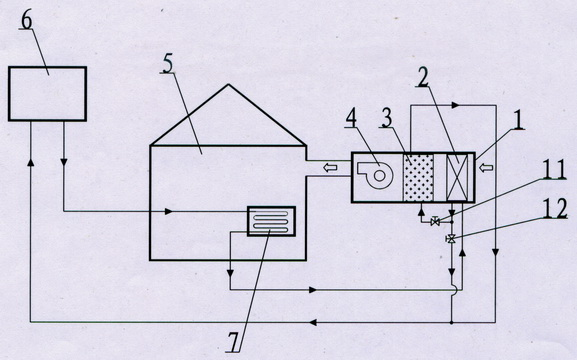

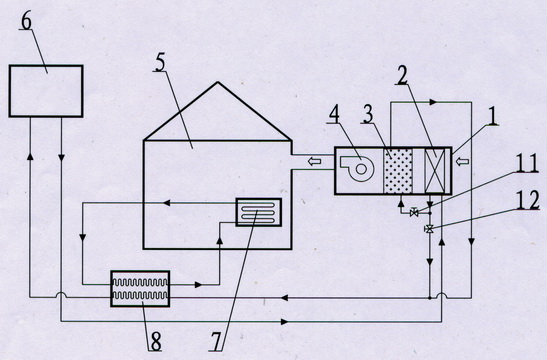

[0034] An air-conditioning system combining an indirect evaporative water chiller and a traditional mechanical refrigeration unit, such as figure 1 As shown, an air-conditioning system combined with an indirect evaporative water chiller and a traditional mechanical refrigeration unit, in the casing of the air handler 1 with an air inlet and an air outlet, surface heat exchangers are installed sequentially from the air inlet to the air outlet 2. The water ring compression refrigeration unit 3 and the blower 4, the outlet pipe of the indirect evaporative chiller 6 is connected to the water inlet of the surface heat exchanger 2 of the air handler 1, and the outlet pipe of the surface heat exchanger 2 is a three-way joint One branch pipe of the water ring compression refrigeration unit 3 is connected to the water inlet of the water ring compression refrigeration unit 3 through the valve 11, the outlet pipe of the water ring compression refrigeration unit 3 is connected to the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com