Method for preparing K4169 alloy by using nickel-base cast high-temperature alloy K4169 returns

A technology of superalloy and return material, applied in the direction of improving process efficiency, can solve problems such as increasing the production cost of the engine, and achieve the effects of good plasticity, excellent lasting performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

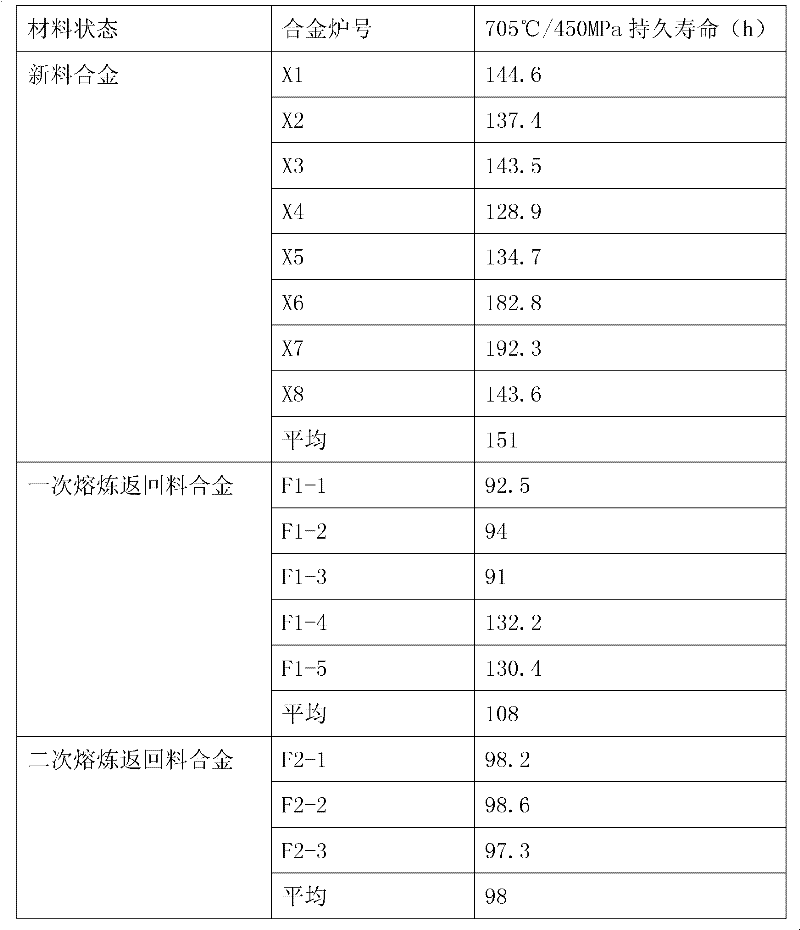

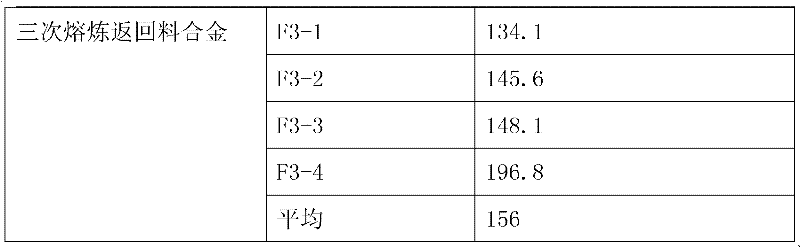

Examples

Embodiment 1

[0035] The process steps of the method for preparing the K4169 alloy by utilizing the returned material of the nickel-based cast superalloy K4169 are as follows.

[0036] (1) K4169 alloy return material pretreatment

[0037] The return materials generated during the production process of K4169 alloy castings, namely risers, runners and waste castings, are subjected to sand blowing treatment, and the return materials are put into the sand blowing machine. Quartz sand, blowing sand on the surface of the returned material, blowing off the scale, mold shell, sticky iron, inclusions and sand inclusions on the surface of the returned material, so that the surface of the material is smooth and free of debris.

[0038] (2) K4169 alloy return material is smelted once

[0039] The vacuum induction melting furnace is used to melt the alloy. The specific operation steps are: when the vacuum degree is ≤1.33Pa, start heating up, and control the heating rate at 13°C / min. When the surface of...

Embodiment 2

[0053] The process steps of the method for preparing the K4169 alloy by utilizing the returned material of the nickel-based cast superalloy K4169 are as follows.

[0054] (1) K4169 alloy return material pretreatment

[0055] The return materials generated during the production process of K4169 alloy castings, namely risers, runners and waste castings, are subjected to sand blowing treatment, and the return materials are put into the sand blowing machine. Quartz sand, blowing sand on the surface of the returned material, blowing off the scale, mold shell, sticky iron, inclusions and sand inclusions on the surface of the returned material, so that the surface of the material is smooth and free of debris.

[0056] (2) K4169 alloy return material is smelted once

[0057] The alloy is smelted in a vacuum induction melting furnace. The specific operation steps are: when the vacuum degree is less than or equal to 1.33Pa, start heating up and control the heating rate at 15°C / min. Whe...

Embodiment 3

[0071] The process steps of the method for preparing the K4169 alloy by utilizing the returned material of the nickel-based cast superalloy K4169 are as follows.

[0072] (1) K4169 alloy return material pretreatment

[0073] The return materials generated during the production process of K4169 alloy castings, namely risers, runners and waste castings, are subjected to sand blowing treatment, and the return materials are put into the sand blowing machine. Quartz sand, blowing sand on the surface of the returned material, blowing off the scale, mold shell, sticky iron, inclusions and sand inclusions on the surface of the returned material, so that the surface of the material is smooth and free of debris.

[0074] (2) K4169 alloy return material is smelted once

[0075] The alloy is smelted in a vacuum induction melting furnace. The specific operation steps are: when the vacuum degree is less than or equal to 1.33Pa, start heating up and control the heating rate at 10°C / min. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com