Tea bag packer

A packaging machine and tea bag technology, which is applied in packaging, transport packaging, food packaging, etc., can solve the problems of low connection strength, short sealing length of tea bag tea bag and cotton thread, etc., so as to avoid cotton thread falling off and prolong sealing The effect of length and strengthening connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

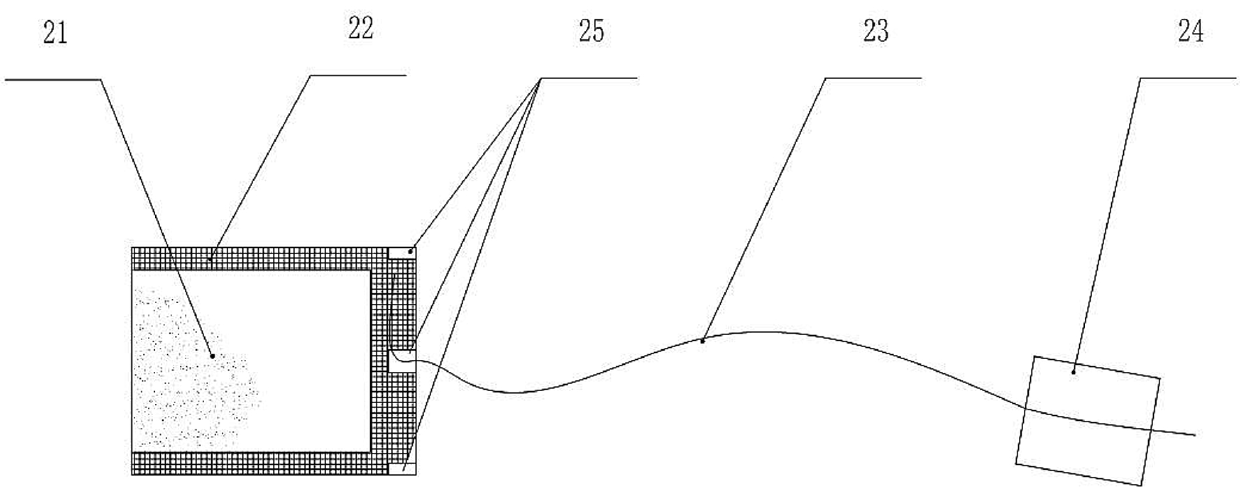

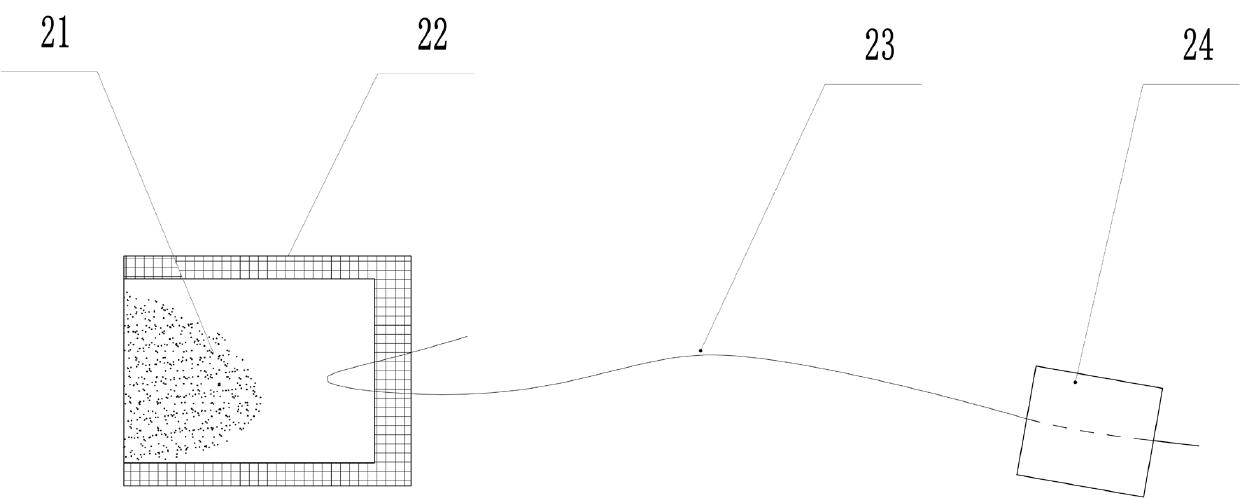

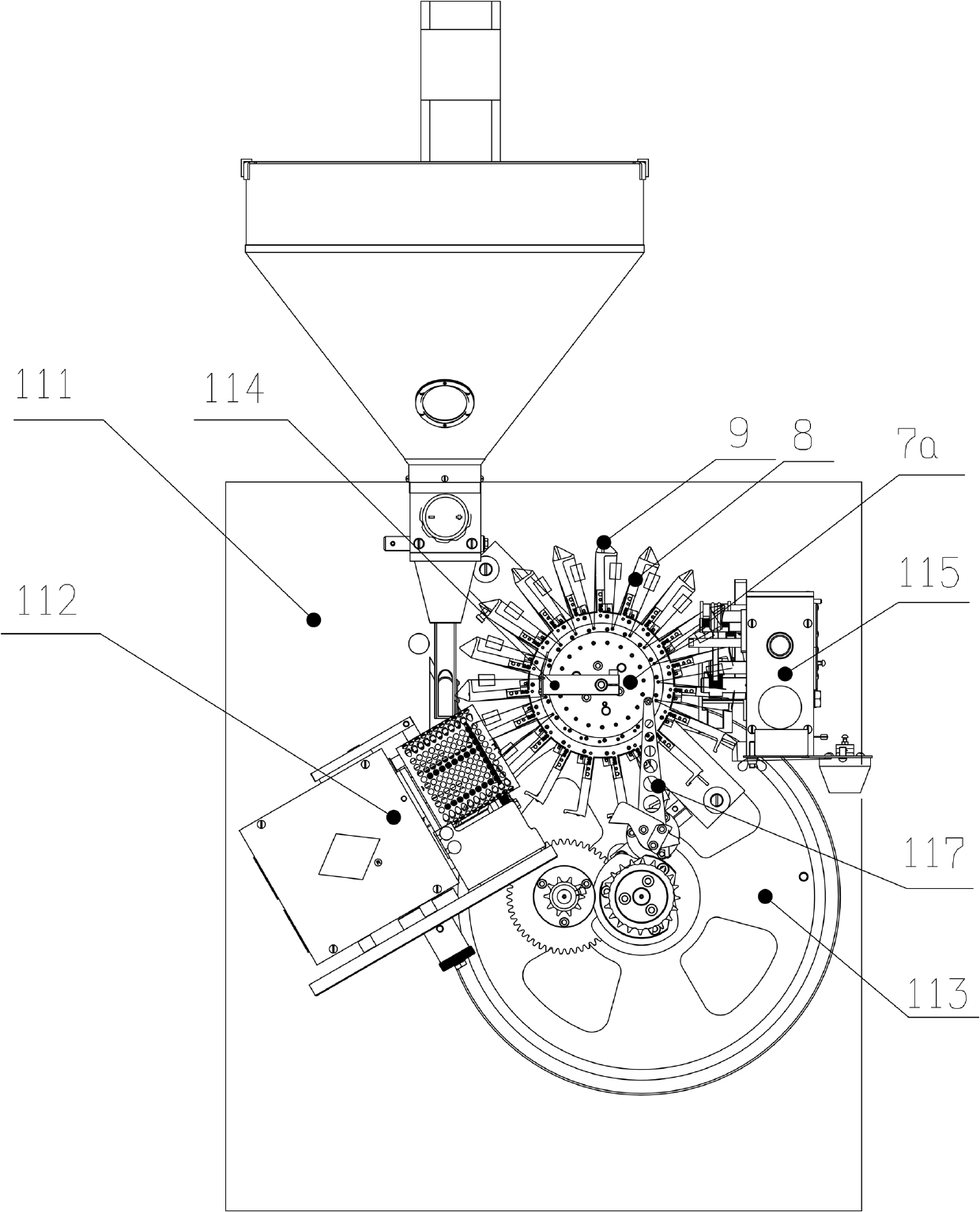

[0015] The specific embodiment of tea bag packaging machine of the present invention is as image 3 , Figure 4 As shown, it includes a frame 111, on which a power assembly 113, a labeling assembly 115, a heat sealing assembly 112, a wire assembly 117, a wire reel assembly 7a and an off-line assembly 114 are arranged, wherein the frame 111 has a front panel 2 and a rear panel 1, and the wire reel assembly includes a central shaft 3 with one end fixed on the rear panel 1 of the frame 111, and the other end of the central shaft 3 is perpendicular to the frame panel and extends axially through the frame front panel 2. On the outer circumference of the central shaft 3, the bearings 13 and 14 positioned at the front and rear ends are rotated and equipped with a shaft sleeve 4, and the shaft sleeve 4 located between the front and rear panels 1 and 2 of the frame is radially fixed by screws 6 The chain wheel 5 that is used to connect the power assembly 113 is arranged, on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com