Tool for bending process of bending press

A press brake and tool technology, applied in the field of press bending tools, can solve the problems of position deviation, inability to perform bending process, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to present the content of the present invention more specifically, the implementation forms of the present invention will be described in detail below with reference to the drawings.

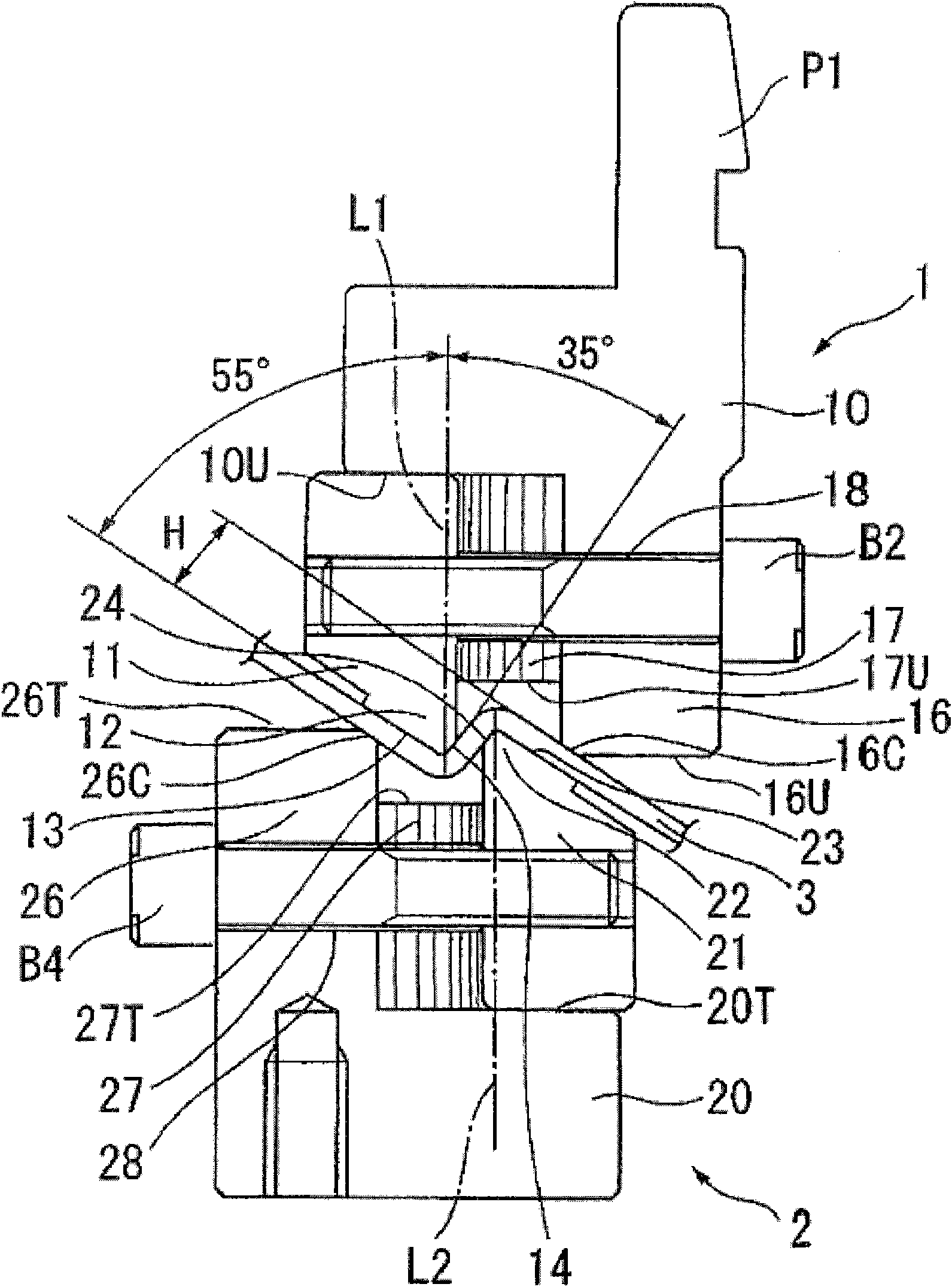

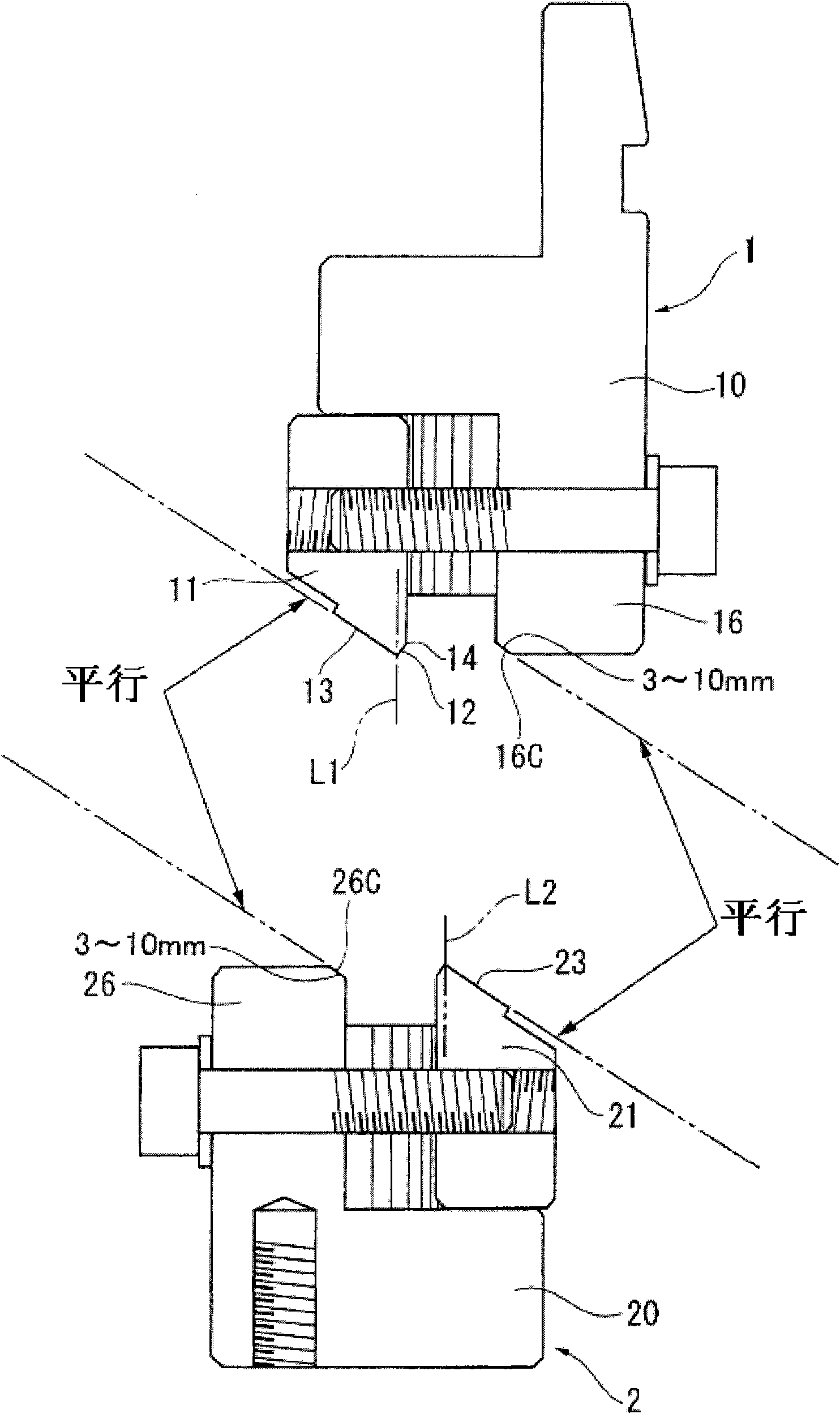

[0035] Such as figure 1 As shown, this bending tool is composed of an upper V-shaped bending die 1 and a lower V-shaped bending die 2.

[0036] The fixing part P1 at the upper end of the upper V-shaped bending die 1 is fixed to the main body of the bending machine with a nut or other suitable locking fittings. This upper V-shaped bending die 1, the V-shaped bending die body 10, is provided with a downwardly protruding blade 11 and a bending processing block 16 (hereinafter Referred to as processing block 16).

[0037] In the structure of the above-mentioned upper V-shaped bending die 1, the V-shaped bending die body 10 and the processing blocks 16 are integrally formed, and the blade 11 is formed after the V-shaped bending die body 10 and each processing block 16 are formed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com