Method for improving structure of conductive adhesive and conductive adhesive

A technology of conductive adhesive and conductive metal, applied in the field of conductive adhesive, can solve the problems of easy peeling off of the proliferative layer, easy overburning, deterioration of physical properties of silica gel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

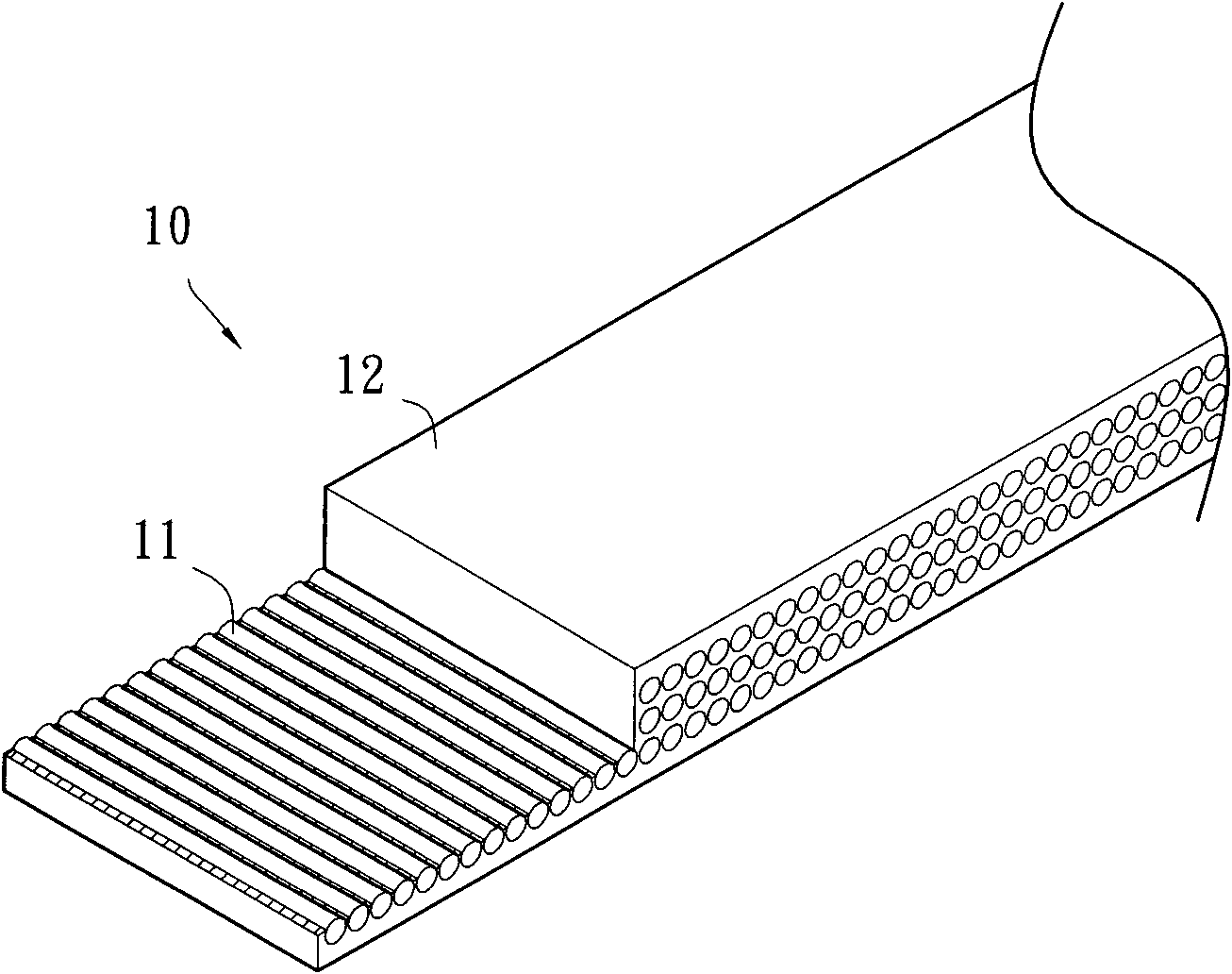

[0028] The basic structure of the existing conductive adhesive is as follows:

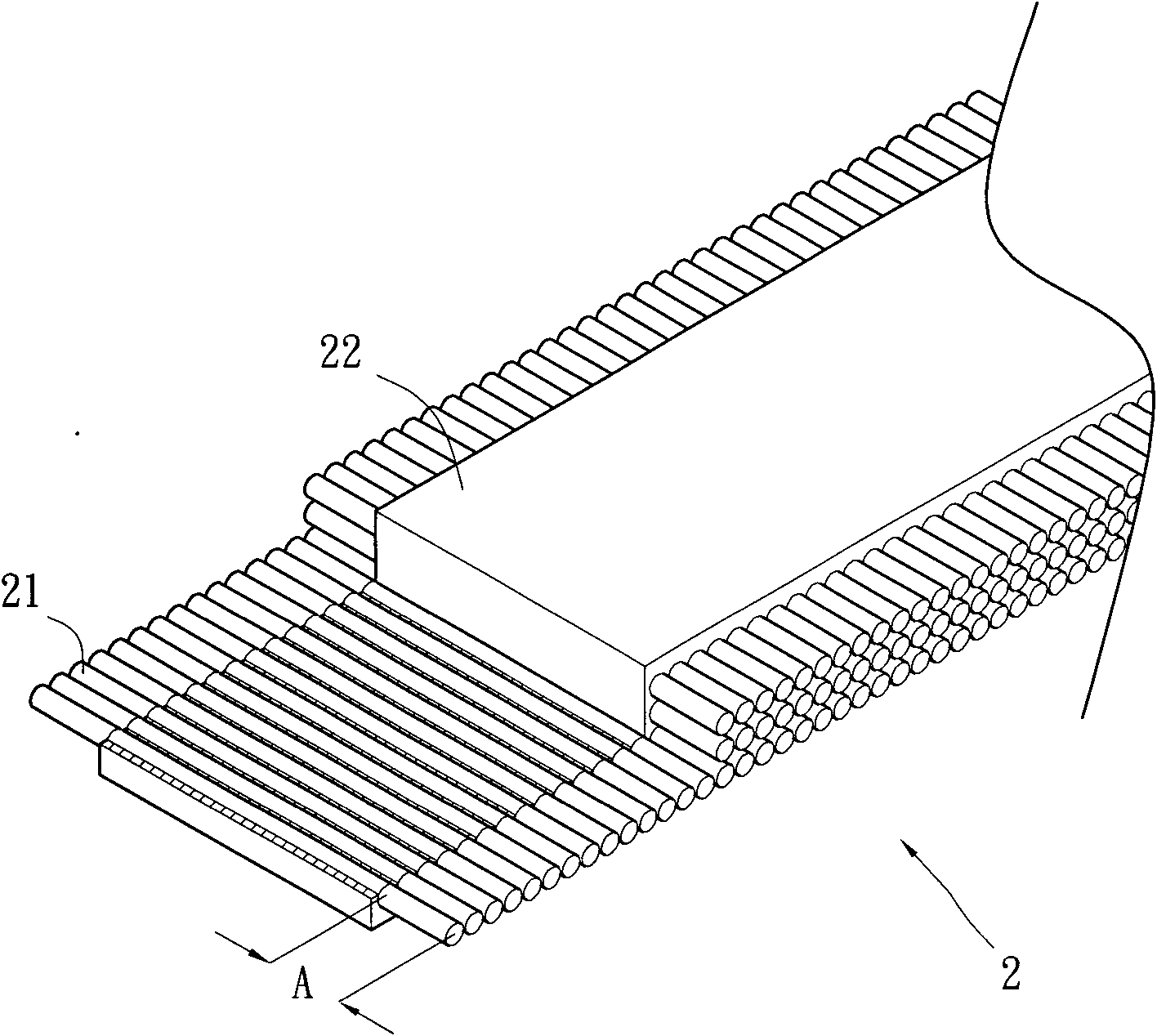

[0029] A plurality of flexible metal cables (such as nickel-plated copper wires or gold-plated copper wires) are arranged in a plane layer parallel to each other and with a fixed distance, and an insulating material film (such as polyethylene paraphenylene) is quantitatively coated on the plane layer Diformic acid ester film (PET film)), the insulating material film is combined with the metal cables to form a conductive metal wire film, and an insulating material (such as: silica gel) is coated on both sides of the conductive metal wire film. an appropriate thickness.

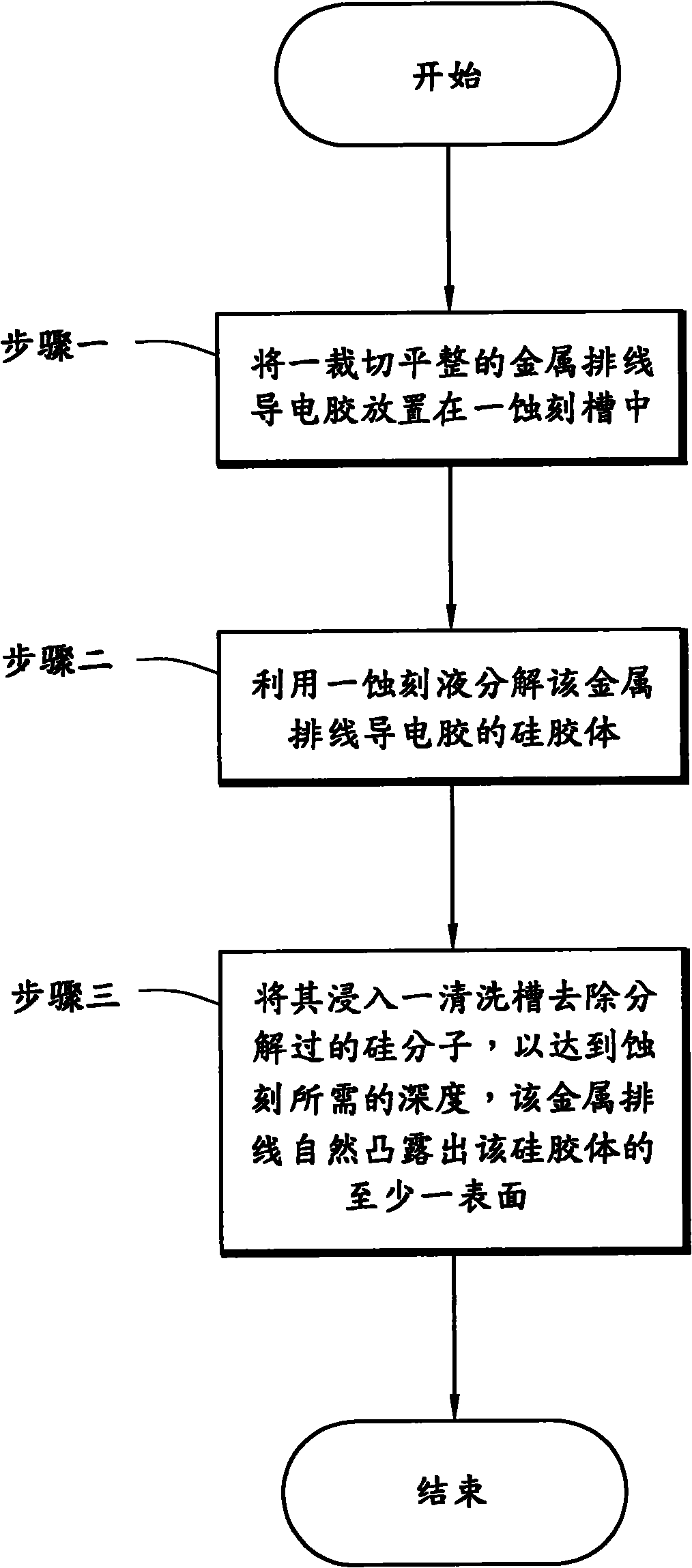

[0030] Based on the basic structure of the existing conductive adhesive, the present invention provides a method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com