Foam glass-based composite radar absorbing material and preparation method thereof

A radar absorbing material, foam glass technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low product purity and difficult process control, achieve simple and easy operation process, reduce radiation pollution, and easy to use raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0031]

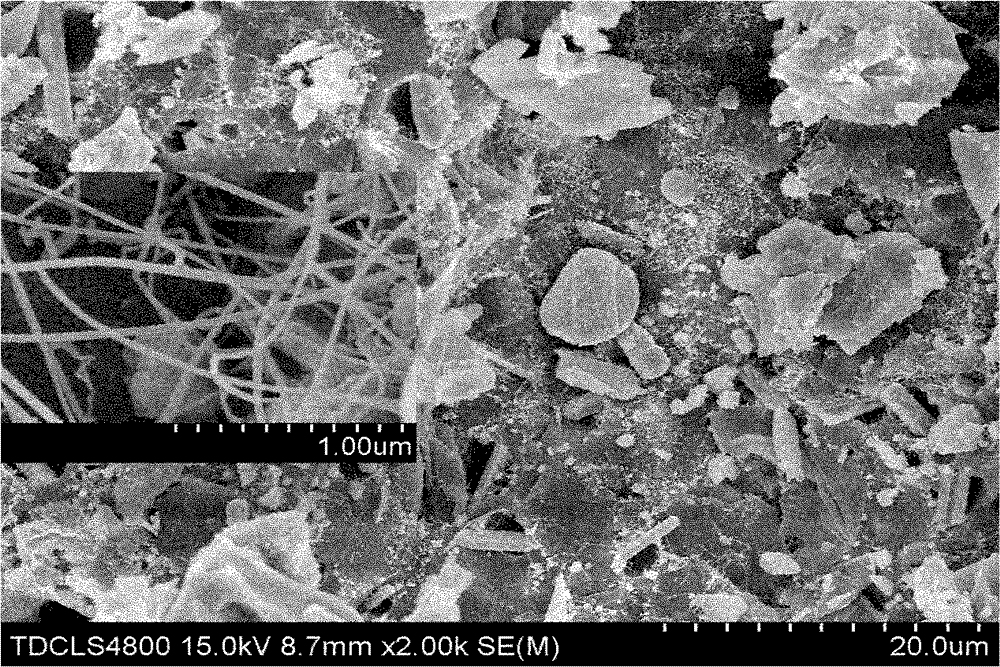

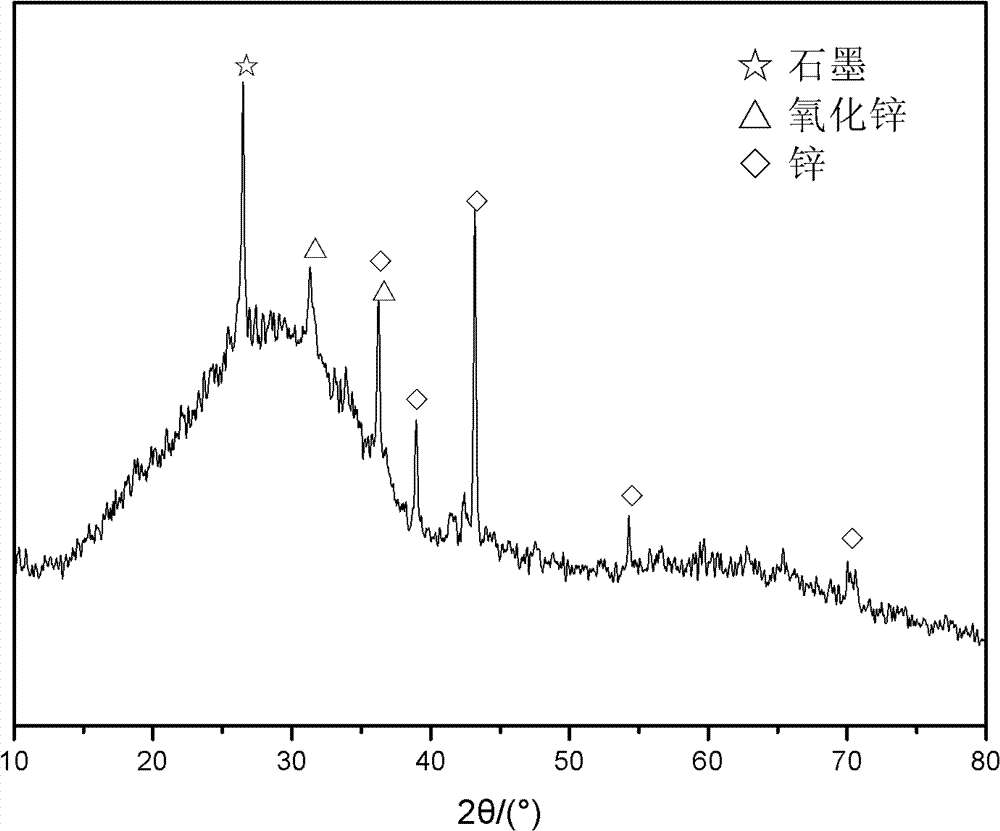

[0032] The above-mentioned embodiments are prepared by the preparation method of the present invention. First, the corresponding raw materials are weighed according to the formula ratio, and then mixed evenly and finely ground to obtain the material to be fired. The dry grinding method can also be adopted, and the mixed material is wet ground with water as the ball milling medium, and the mixed material is fully mixed. The amount of balls to be added is based on the mass ratio of materials to be fired: grinding balls is 1:2, and the ball is milled at a speed of 600r / min for 3 hours. When the obtained slurry is heated and dried in a drying oven, the formation of slurry agglomeration should be prevented. , the mixture should be turned and smashed from time to time, and finally passed through a 140-mesh sieve, and the uniformly mixed mate...

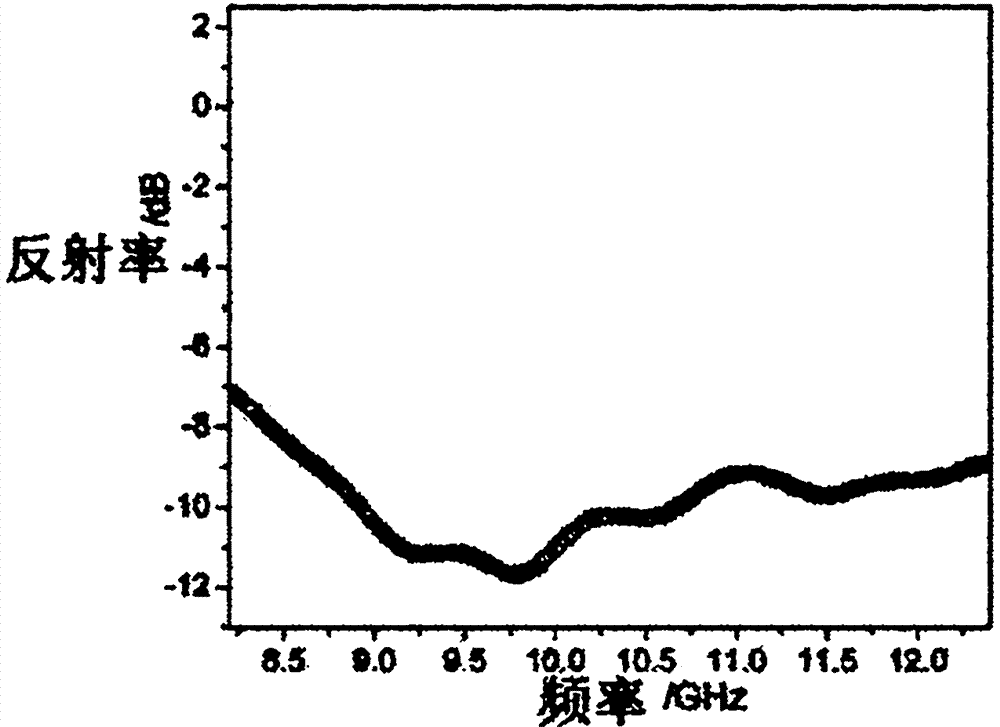

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com