Automatic oiling machine for automobile production line

A technology for automobile production lines and fuel dispensers, which is applied to engine components, engine lubrication, mechanical equipment, etc., can solve problems such as affecting the smoothness of the movement of the conveying skid, reducing the movement accuracy of the conveying skid, and increasing the labor of workers, etc. Smoothness and precision, ensure smoothness and precision, ensure good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

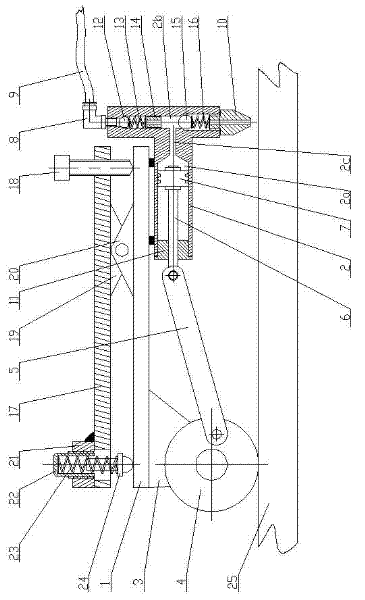

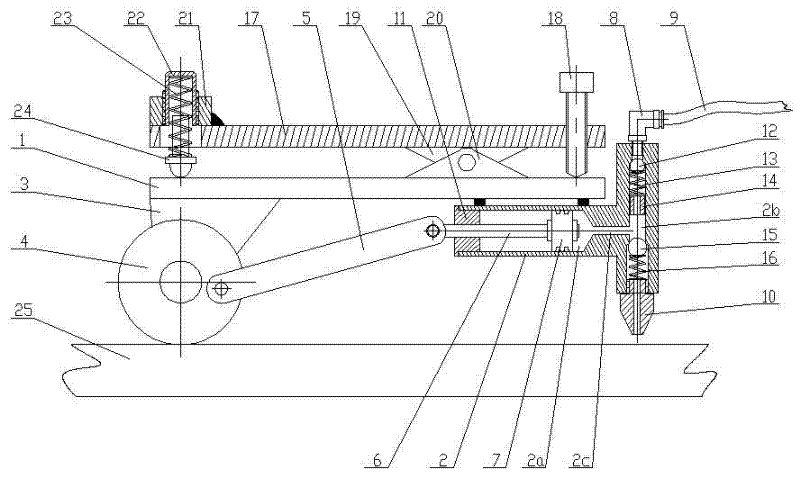

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0016] Such as figure 1 As shown, the present invention consists of a connecting plate 1, a cylinder body 2, a bracket 3, a transmission wheel 4, a connecting rod 5, a piston rod 6, a piston assembly 7, an oil pipe joint 8, an oil inlet pipe 9, an oil injection nozzle 10, a first one-way Valve, the second one-way valve, piston rod bracket 11, mounting plate 17, jacking bolt 18, first lug 19, second lug 20 and pressure adjustment mechanism. Wherein the connecting plate 1 is a flat plate structure, and a cylinder body 2 is arranged on the right end of the connecting plate 1 as shown in the figure, and the cylinder body 2 is composed of a horizontal section on the left and a vertical section on the right, and the right end of the horizontal section is vertically connected with the middle part of the vertical section. And the transverse section is fixed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com