Method for manufacturing wheels of engineering vehicle

A manufacturing method and technology for engineering vehicles, which can be applied in the directions of wheels, vehicle parts, transportation and packaging, etc., and can solve the problems of increasing the amount of cold spinning processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

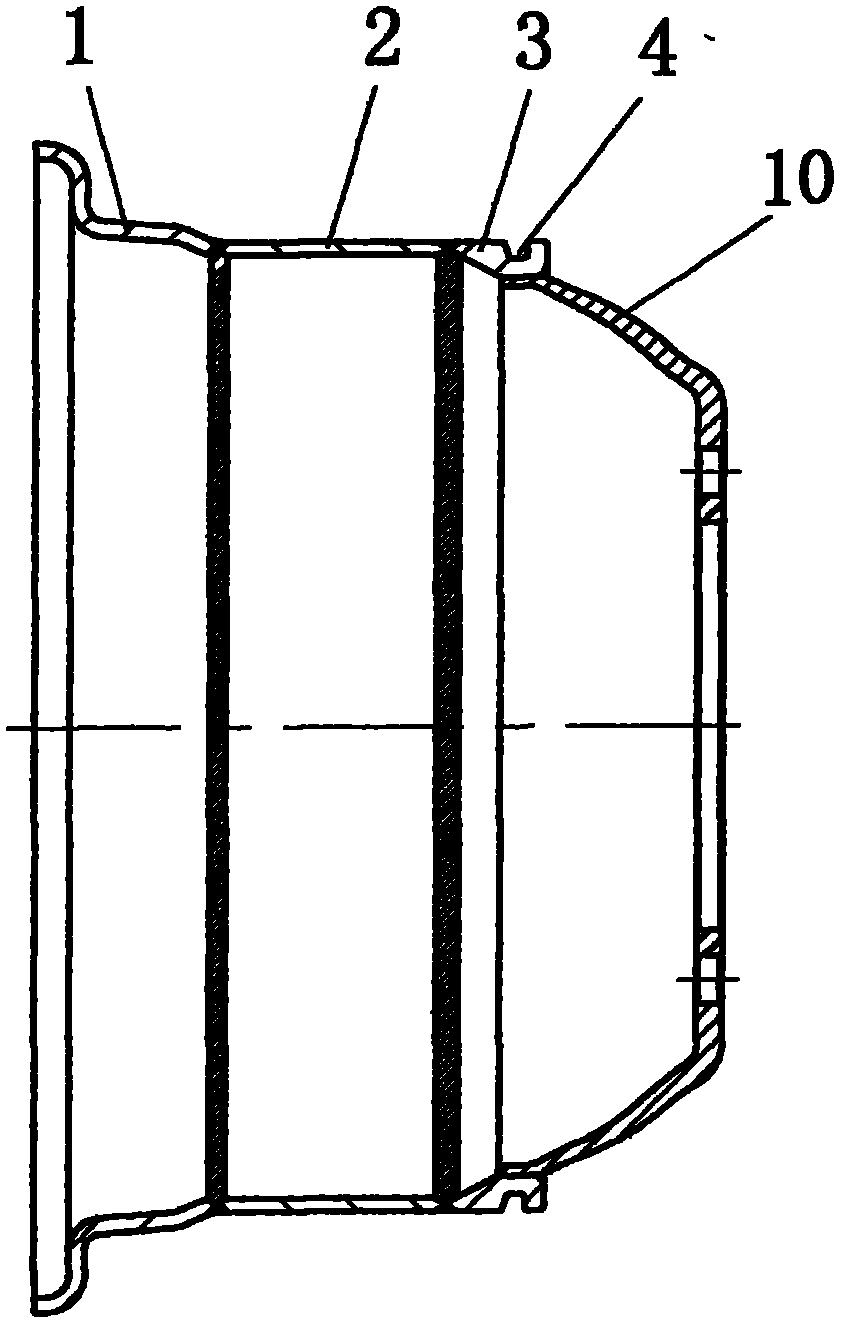

[0012] The structure of the original engineering vehicle wheel is as follows: image 3 As shown, the rim is welded by small opening section 3, straight line section 2 and bead seat 1, and the small opening section, straight line section and bead seat are respectively formed by blanking and coil welding of shaped steel strips. There is a lock ring groove 4 on the small mouth section. Wheel rim and spoke 10 are welded together again, become a wheel.

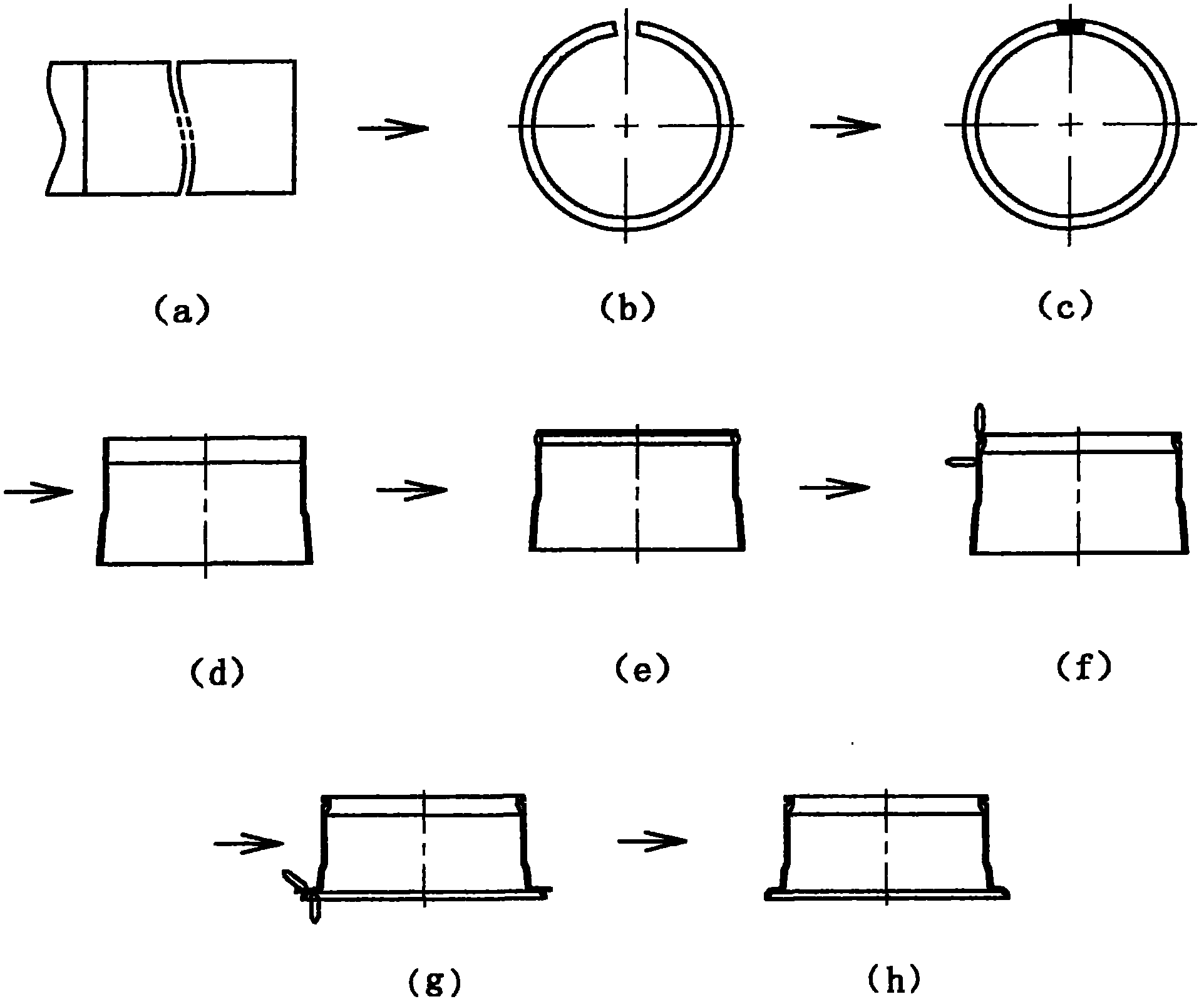

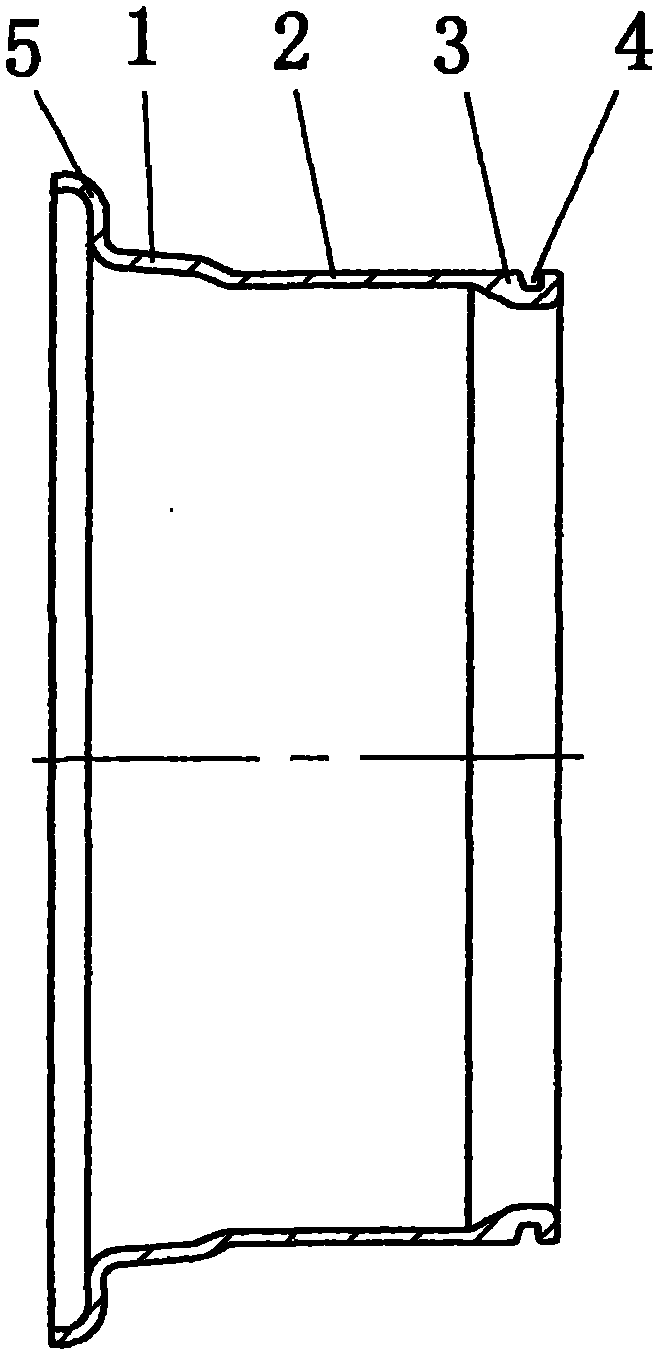

[0013] Such as figure 1 As shown, the manufacturing method of the wheel rim of this engineering vehicle wheel proposed by the present invention comprises (a) blanking of flat steel strip, (b) circle circle, (c) welding, (d) big head flaring, (e) small mouth End rotary hot upsetting, (f) small mouth section, straight section and bead seat cold spinning forming, (g) wheel flange spinning forming, (h) turning two ports. The wheel rim of engineering vehicle made by this method is as follows: figure 2 shown. Since the small mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com