Small electromechanical transducer, in particular a timepiece generator

A sensor and electromechanical technology, applied in electromechanical devices, electric winding, electric mechanical clocks, etc., can solve problems such as troublesome and complicated manufacturing, and achieve the effect of reducing costs and increasing duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

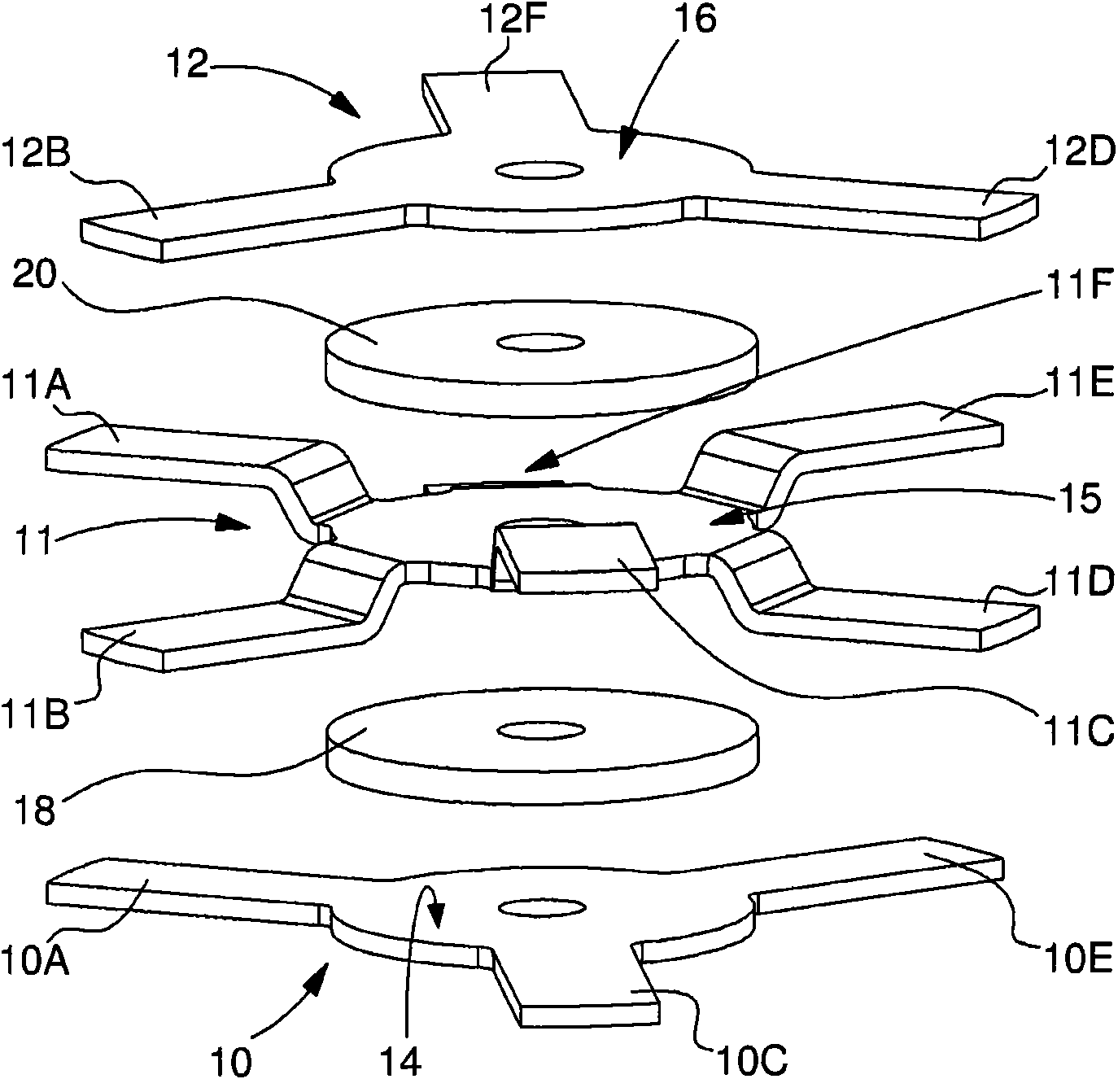

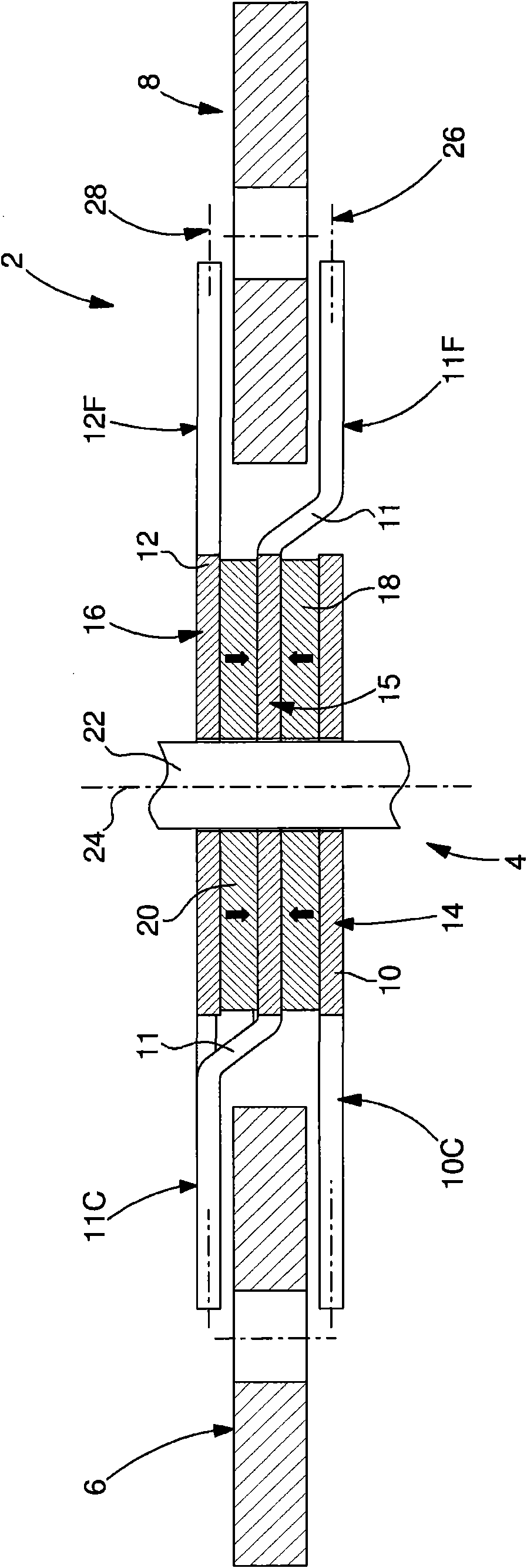

[0013] Refer to attached Figures 1 to 3 , in the following we will describe a preferred embodiment of a clock-type electromechanical sensor according to the present invention. In particular, the sensor forms a magnetoelectric generator 2 . The generator 2 comprises a rotor 4 and two planar coils 6 and 8 . It will be noted immediately that in the first variant only one coil 6 is provided; but in the second variant there are 3 coils, angularly deflected by 120°. The coils 6 and 8 have an angular deflection of 120° relative to the axis of rotation 20 of the rotor 4 .

[0014] The rotor 4 is formed by first, second and third parts 10, 11 and 12 made of magnetic material. The first magnetic portion 10 is formed by a planar structure defining a first central region 14 and three tongues 10A, 10C and 10E extending radially from the central region 14 . The three tongues are arranged in a uniform manner with an angular deflection of approximately 120°. The magnetic portion 10 thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com