Heat preserving cotton and production method thereof

A production method and technology of thermal insulation cotton, applied in the field of thermal insulation cotton, can solve the problems of poor flexibility of thermal insulation cotton, prone to wrinkles and pits on the surface, and low strength, and achieve the effect of good uniformity, high flexibility and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

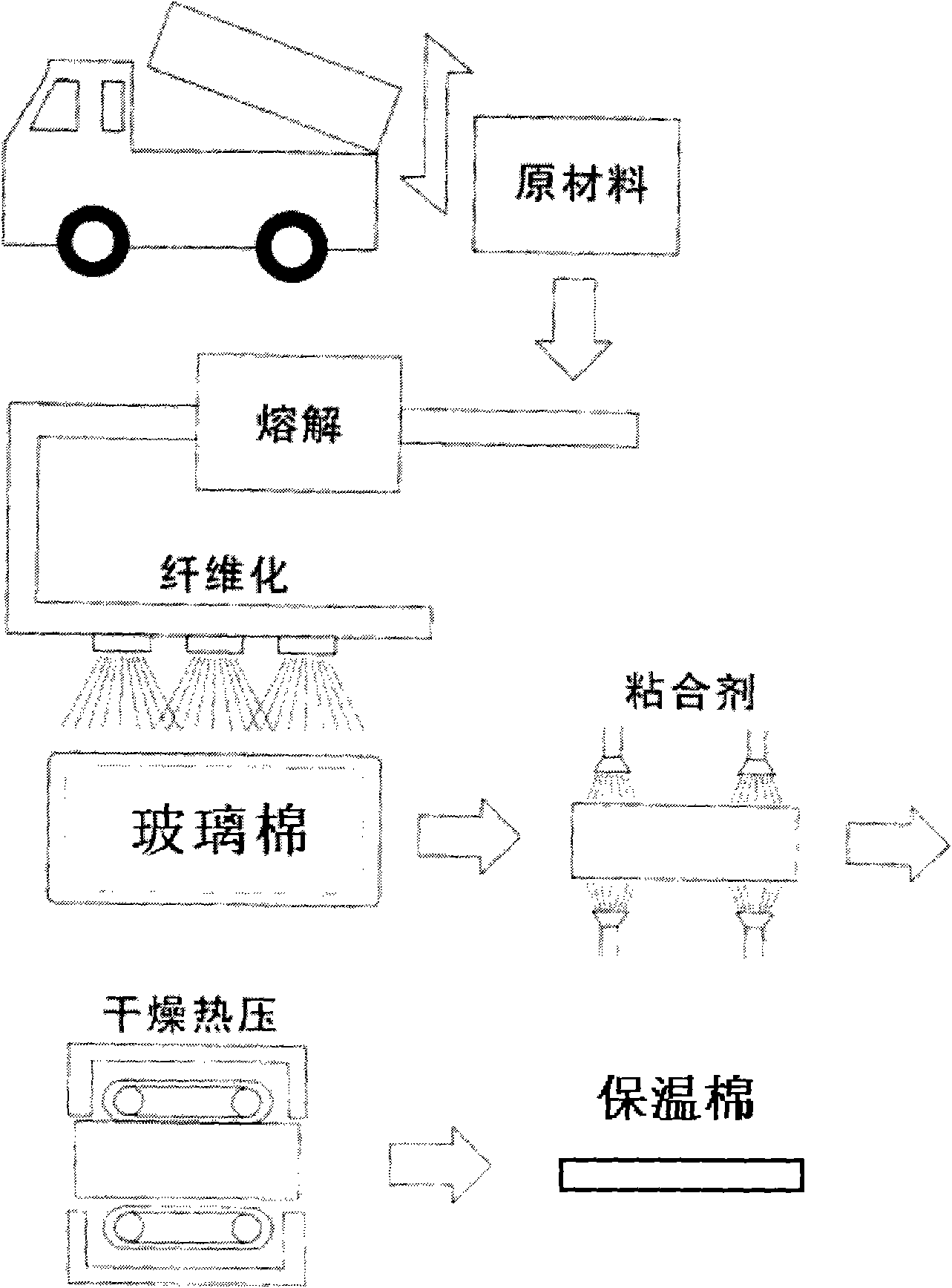

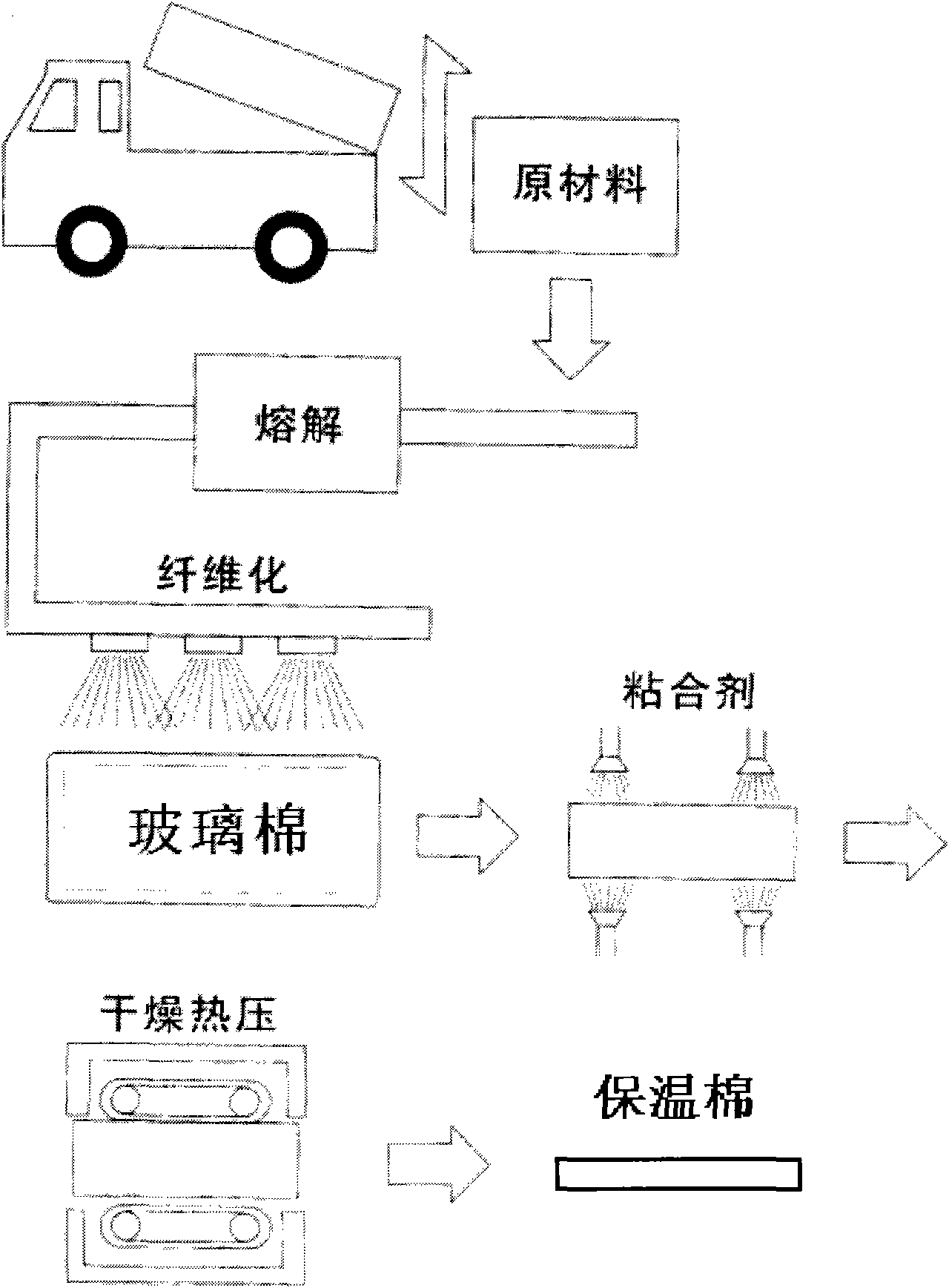

Method used

Image

Examples

Embodiment 1

[0027] A thermal insulation cotton, which is composed of the following materials: broken glass: 460 parts; feldspar 70 parts; borax pentahydrate 70 parts; soda ash 45 parts; dolomite 17 parts; cold water material 80 parts.

[0028] The method of above-mentioned insulation cotton is:

[0029] (a) reclaim cullet, clean and break it;

[0030] (b) Prepare raw materials: feldspar, borax, soda ash, and analyze the composition of raw materials;

[0031] (c) According to requirements: cullet: 460 parts; 70 parts of feldspar; 70 parts of borax pentahydrate; 45 parts of soda ash; 17 parts of dolomite; Weigh and mix to make a batch; SiO in the batch 2 64.5%; AL 2 o 3 with Fe 2 o 3 The sum is 2.7%; B 2 C 3 is 4.8%; the sum of CaO and MgO is: 10.8%; Na 2 O and K 2 The sum of O is 14.9%, other substances 0.3%;

[0032] (d) Dissolving the batch material to obtain uniform, pure and transparent glass liquid;

[0033] (e) Leading the molten glass into a centrifuge for fiberization ...

Embodiment 2

[0037] A thermal insulation cotton, which is composed of the following materials: broken glass: 485 parts; feldspar 72 parts; borax decahydrate 95 parts; soda ash 46 parts; dolomite 18 parts; cold water material 90 parts.

[0038] The method of above-mentioned insulation cotton is:

[0039] (a) reclaim cullet, clean and break it;

[0040] (b) Prepare raw materials: feldspar, borax, soda ash, and analyze the composition of raw materials;

[0041] (c) According to requirements: cullet: 485 parts; 72 parts of feldspar; 95 parts of borax decahydrate; 46 parts of soda ash; 18 parts of dolomite; Weigh and mix to make a batch; SiO in the batch 2 67%; AL 2 o 3 with Fe 2 o 3 The sum is 2.5%; B 2 C 3 4.8%; the sum of CaO and MgO: 11%; Na 2 O and K 2 The sum of O is 14.5%, other substances 0.2%;

[0042] (d) Dissolving the batch material to obtain uniform, pure and transparent glass liquid;

[0043] (e) Leading the molten glass into a centrifuge for fiberization to obtain gl...

Embodiment 3

[0047] A thermal insulation cotton, which is composed of the following materials: broken glass: 480 parts; feldspar 75 parts; borax decahydrate 92 parts; soda ash 50 parts; dolomite 20 parts; cold water material 85 parts.

[0048] The method of above-mentioned insulation cotton is:

[0049] (a) reclaim cullet, clean and break it;

[0050] (b) Prepare raw materials: feldspar, borax, soda ash, and analyze the composition of raw materials;

[0051] (c) According to requirements: cullet: 480 parts; 75 parts of feldspar; 92 parts of borax decahydrate; 50 parts of soda ash; 20 parts of dolomite; Weigh and mix to make a batch; SiO in the batch 2 66.8%; AL 2 o 3 with Fe 2 o 3 The sum is 2.9%; B 2 C 3 5.1%; the sum of CaO and MgO: 10.5%; Na 2 O and K 2 The sum of O is 13.5%, other substances 0.2%;

[0052](d) Dissolving the batch material to obtain uniform, pure and transparent glass liquid;

[0053] (e) Leading the molten glass into a centrifuge for fiberization to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com