Halogen flame retardant thermoplastic polyurethane

A thermoplastic polyurethane, flame retardant technology, used in insulated cables, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

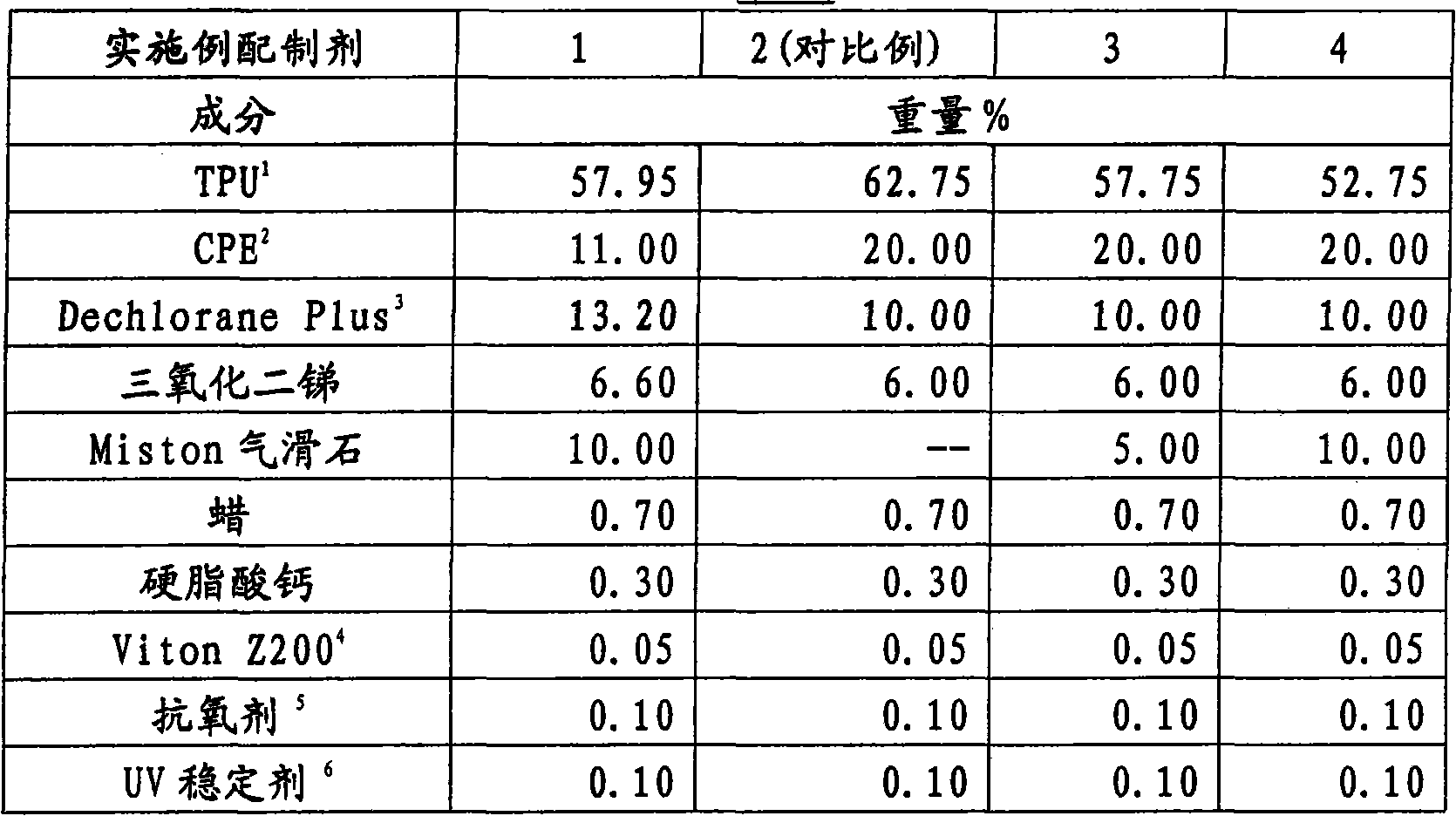

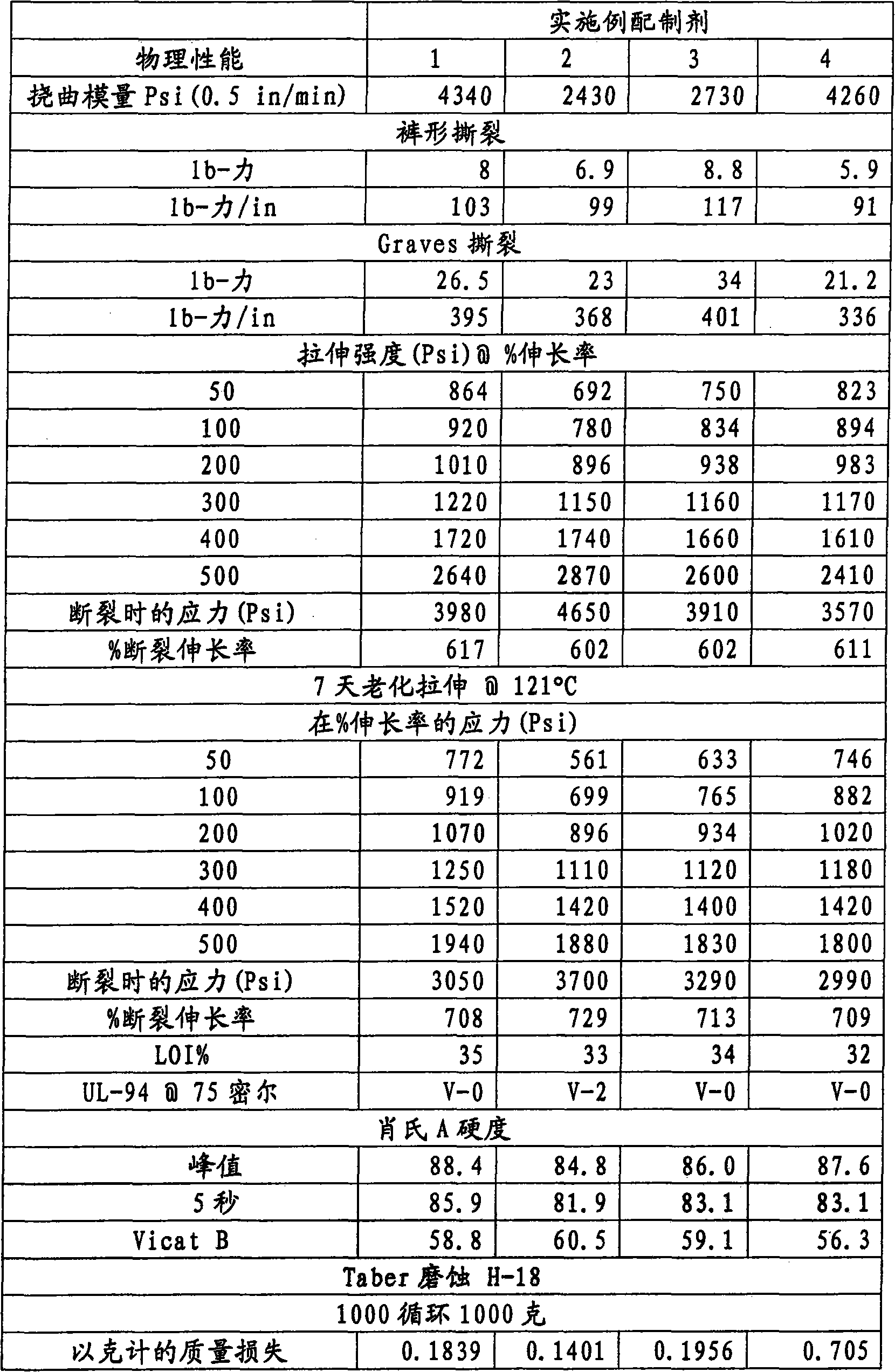

[0063] Examples 1-4 serve to demonstrate the effect of talc in halogenated flame retardant TPU formulations. The TPU used is a polyether TPU with 85 Shore A durometer. Example 2 is a comparative example without talc.

[0064] The results showed that the talc-free formulation of Example 2 (comparative example) was rated V-2 in the UL-94 test. Examples 1, 3 and 4 all showed V-0 ratings. It is very surprising that 5.0 wt% talc will improve the UL-94 performance from V-2 to V-0. The LOI% results were greater than 30 for all formulations.

[0065] The formulations and results for Examples 1-4 are shown in Tables I and II below, respectively.

[0066] Table I

[0067]

[0068] 1 TPU is polyether TPU with 85 Shore A hardness, made of 1000M n PTMEG, butanediol and MDI prepared, available from Lubrizol Advanced Materials, Inc. as Estane 58325 purchased.

[0069] 2 CPE is chlorinated polyethylene, available from Dow Chemical as Tyrin CM0132 was purchased.

[0070] 3 De...

Embodiment 5-7

[0077] Examples 5-7 are used to demonstrate flame retardant TPU formulations containing chlorine based flame retardants and antimony trioxide and talc. The TPU used in Examples 5-7 was an 85 Shore A durometer polyether TPU with 0.15% by weight trimethylpropane for light crosslinking and build weight average molecular weight.

[0078] All formulations showed a UL-94 test rating of V-0 with high LOI %.

[0079] The formulations and test results for Examples 5-7 are shown in Tables III and IV below, respectively.

[0080] Table III

[0081]

[0082] 7 TPU is polyether TPU with 85 Shore A hardness, made of 1000M n PTMEG, butanediol and MDI and 0.15% by weight trimethylpropane (TMP) prepared, available from Lubrizol Advanced Materials, Inc. as Estane 58315 purchased.

[0083] 2 CPE is chlorinated polyethylene, available from Dow Chemical as Tyrin CM0132 was purchased.

[0084] 3 Dechlorane Plus is C 18 h 12 Cl 12 Chlorinated flame retardants, available from OxyCh...

Embodiment 8

[0091] Examples 8 and 9 are used to demonstrate the mixing of two levels of talc (10% and 5% by weight) with a chlorinated flame retardant into a 95 Shore A hardness polyether TPU. Both formulations showed a UL-94 test rating of V-0 at 75 mils. The formulation with 10% by weight talc (Example 8) had an LOI% of 33 and the formulation with 5% by weight talc had an LOI% of 32. These examples show that even small amounts of talc are sufficient to obtain an LOI% of at least 30.

[0092] The formulations and test results for Examples 8-9 are shown in Tables V and VI below, respectively.

[0093] Table V

[0094]

[0095] 8 TPU is a 95 Shore A durometer polyether TPU available from Lubrizol Advanced Materials, Inc. as Estane 58212 purchased.

[0096] 2 CPE is chlorinated polyethylene, available from Dow Chemical as Tyrin CM0132 was purchased.

[0097] 3 Dechlorane Plus is C 18 h 12 Cl 12 Chlorinated flame retardants, available from OxyChem purchased.

[0098] 4 Vit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com