Injection molding method and injection molding die

一种注塑成形、模具的技术,应用在仪器、分析材料等方向,能够解决接合面变形平面性、局限成形件、贯通孔脱模阻力大等问题,达到脱模阻力减小、防止平面性的降低、脱模阻力小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

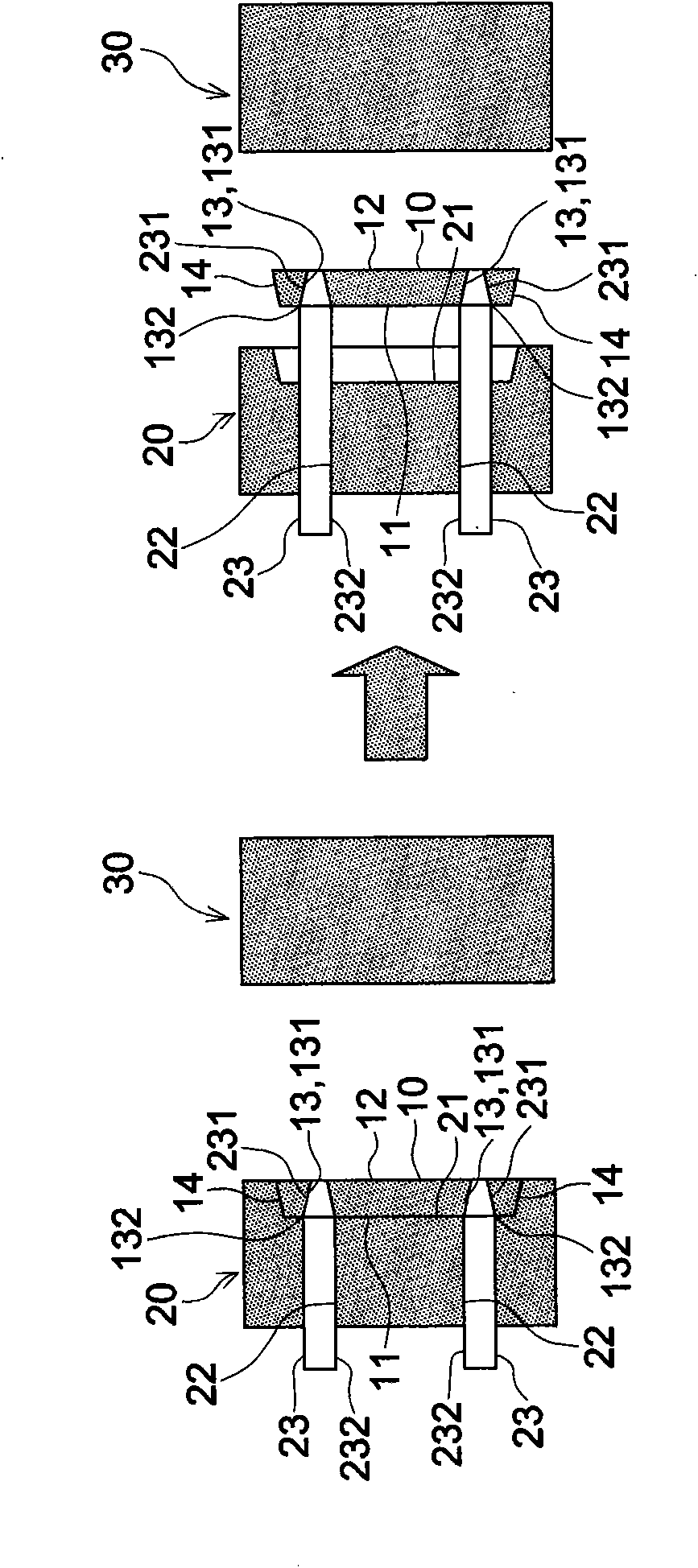

[0072] refer to figure 1 An injection molding die according to a first embodiment of the present invention will be described. figure 1 is a cross-sectional view of an injection molding die.

[0073] First, the plate-shaped substrate 10 molded using the injection molding die of the first embodiment will be described. The substrate 10 is provided with a through-hole 13 penetrating therethrough such that the diameter of the hole gradually decreases from one side surface 11 to the other side surface 12 . On the other side surface 12, a fine flow path (not shown) communicating with the through hole 13 is provided. A covering member (not shown) is bonded to the other side surface 12 on which the fine flow path 12 is provided. A microchip is constituted by the substrate 10 and a cover member bonded to the other side surface 12 of the substrate 10 . One side 11 of the substrate 10 is a flat surface without fine flow paths. In addition, the other side 12 on which the fine flow p...

no. 2 approach

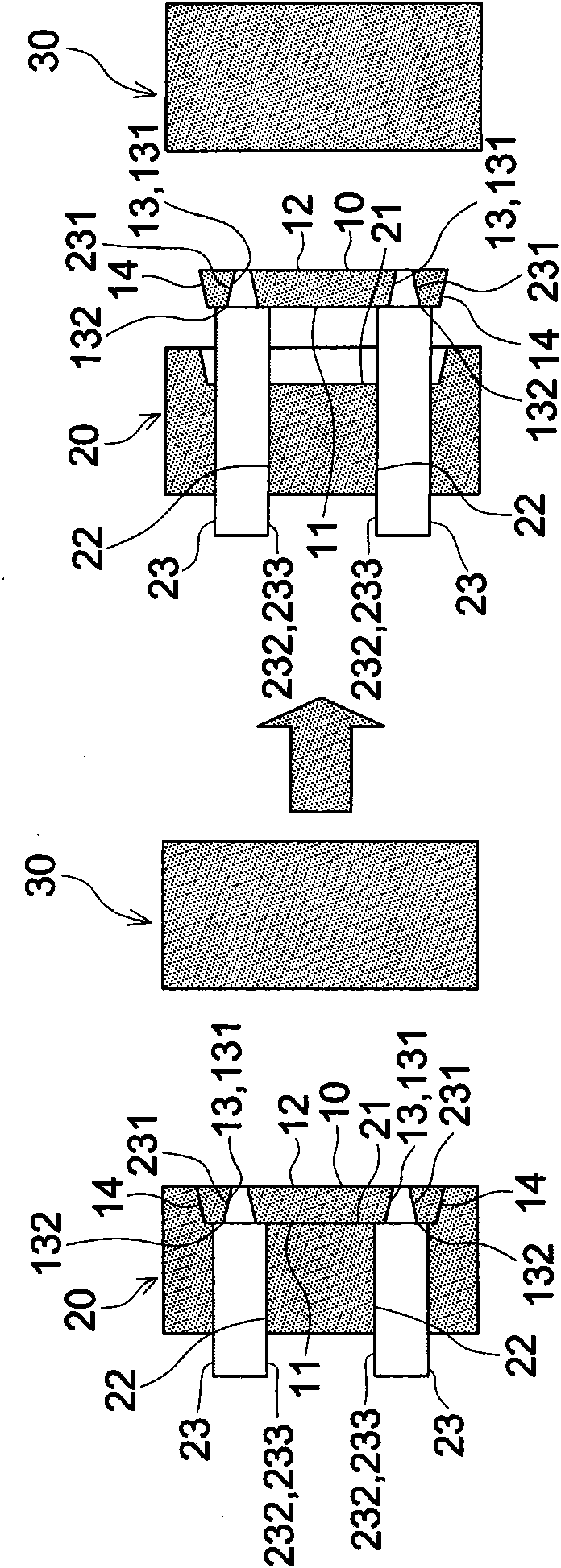

[0109] Below, refer to Figure 4 The injection molding die of the second embodiment will be described. Figure 4 It is a cross-sectional view of the injection molding die of the second embodiment.

[0110] First, the substrate 10 molded by the injection molding die of the second embodiment will be described. The board|substrate 10 of 2nd Embodiment differs from the board|substrate 10 of 1st Embodiment in that it has the cylindrical part (vent tube) 15. As shown in FIG.

[0111] The cylindrical portion 15 protrudes from one side 11 of the substrate 10 to the side opposite to the other side 12 . The other side 12 is a joint surface forming a fine flow path. Figure 4 (c) is a plan view showing the one-side mold 20 and the other side surface 12 (joint surface) of the substrate 10 with the other-side mold 30 opened.

[0112] The cylindrical portion 15 has a height that is three times or more the thickness of the substrate 10 . The height of the cylindrical portion 15 is gener...

no. 3 approach

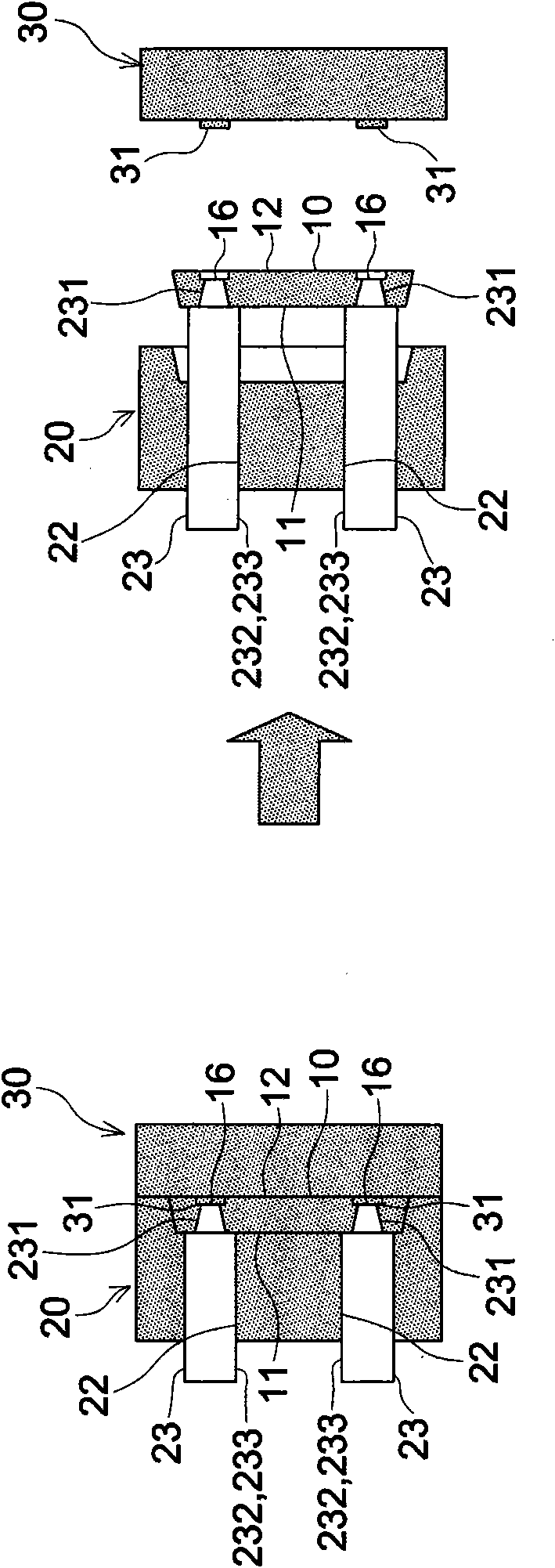

[0138] Below, refer to Figure 6 An injection molding die according to a third embodiment will be described. Figure 6 It is a cross-sectional view of the injection molding die of the third embodiment.

[0139] The injection molding die of the third embodiment is characterized in that the sleeve 24 of the second embodiment is not provided. In the third embodiment, the through hole 13 also penetrates through the center of the cylindrical portion 15 , and the mold release resistance of the through hole 13 is relatively large.

[0140] In the injection molding method of the third embodiment, there is included a pre-separation step of moving the tapered rod 23 toward the substrate 10, that is, the molded product, before the ejection step of the die 20 on the side where the molded product is separated by the tapered rod 23. The mold 30 on the other side sinks in the opposite direction, so that the inner wall 131 of the through hole 13 is separated from the tapered rod 23 .

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com