Method for manufacturing touch panel

A manufacturing method and touch panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of high resistance, metal oxidation, and high sensing series resistance, and achieve improved Reliability, reduction of manufacturing cost, effect of reduction of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

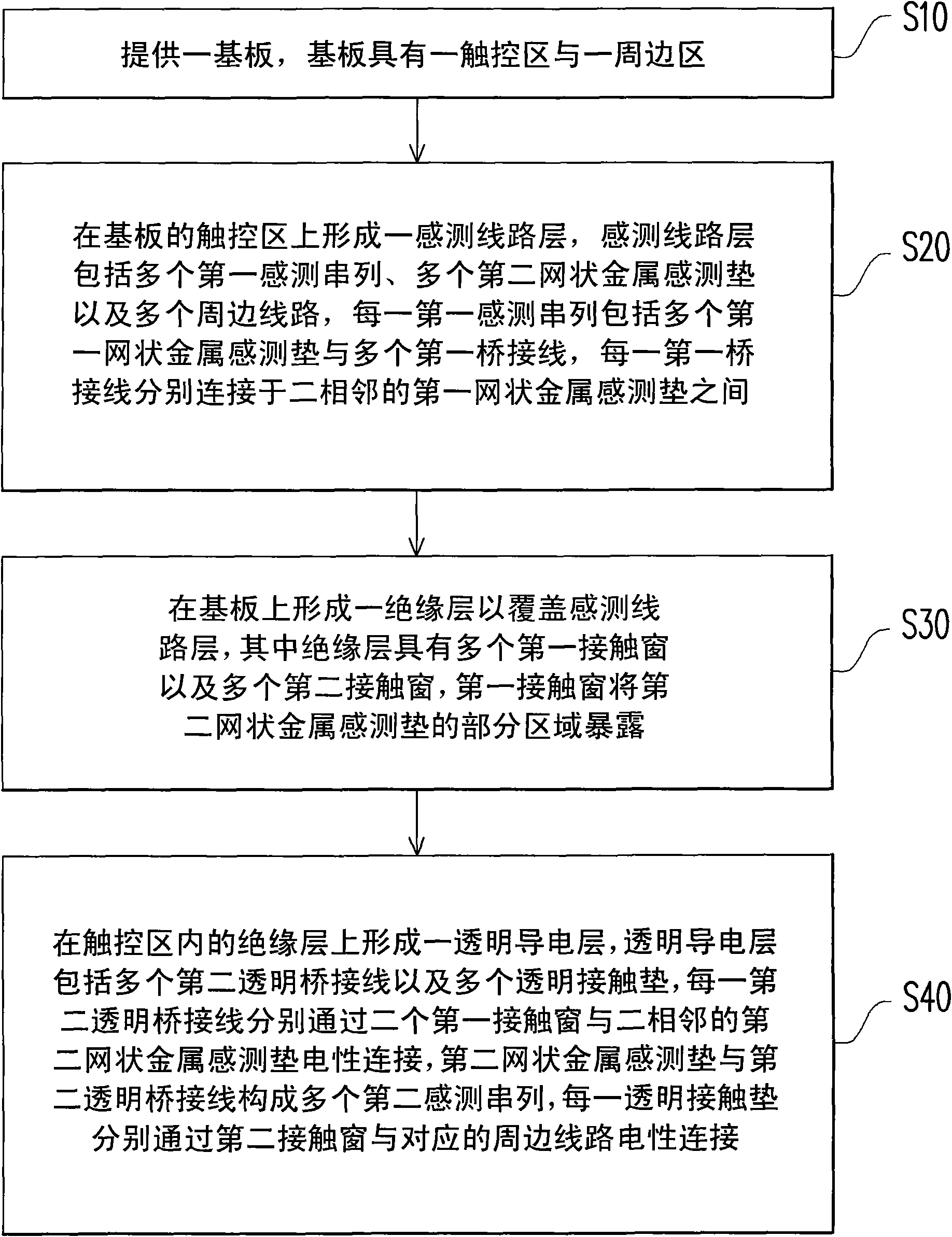

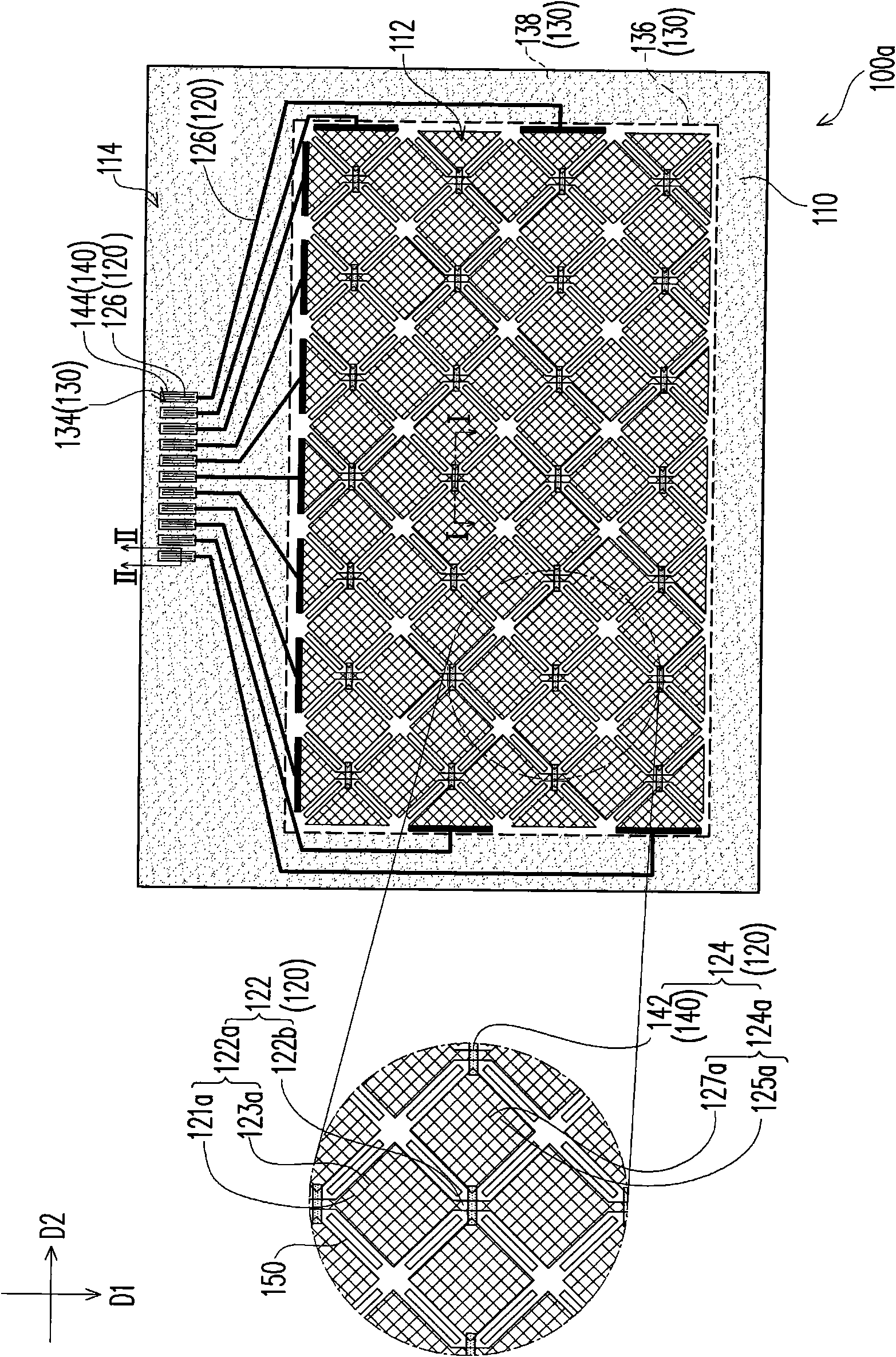

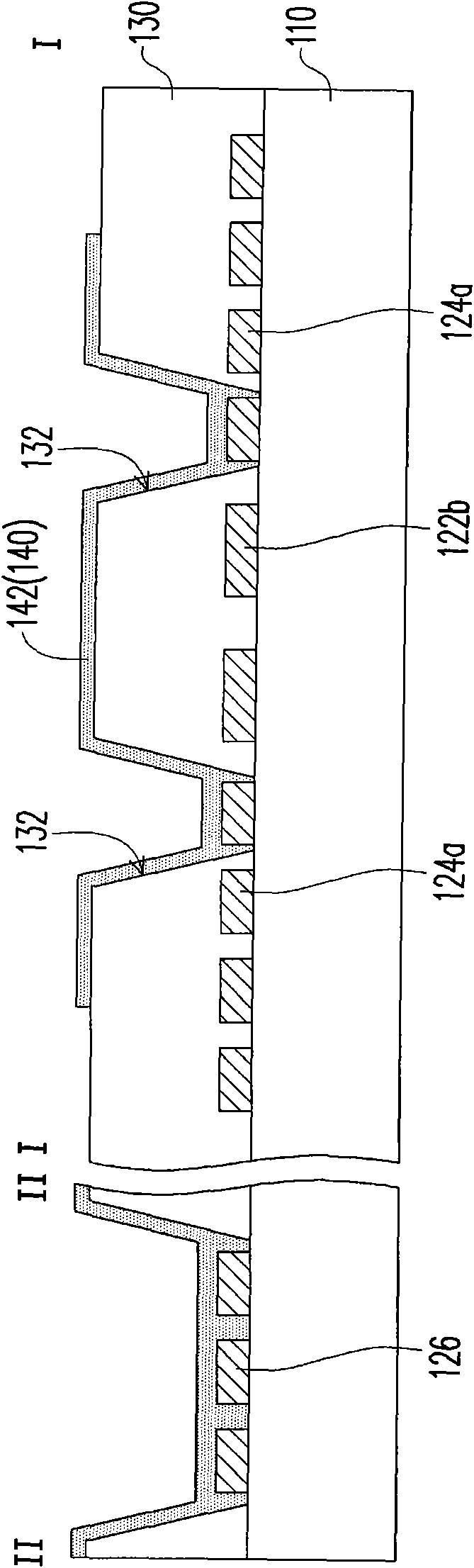

[0045] figure 1 It is a flowchart of a manufacturing method of a touch panel according to an embodiment of the present invention, Figure 2A is a schematic top view of a touch panel according to an embodiment of the present invention, and Figure 2B for along Figure 2A Schematic cross-section of the line I-I. Please also refer to figure 1 and Figure 2A , The manufacturing method of the touch panel of this embodiment includes step S10 to step S40. Firstly, a substrate 110 is provided (step S10 ), wherein the substrate 110 has a touch area 112 and a peripheral area 114 . In this embodiment, the substrate 110 is, for example, a glass substrate, a plastic substrate, a printed circuit board or a display panel.

[0046] Next, please also refer to the figure 1 and Figure 2A , forming a sensing circuit layer 120 on the touch area 112 of the substrate 110 (step S20). In detail, the sensing circuit layer 120 includes a plurality of first sensing series 122, a plurality of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com