Outer frame shading adhesive film for display screen

A technology for shading glue and display screen, applied in optics, nonlinear optics, instruments, etc., can solve the problems of affecting shading efficiency, leaving fingerprints, uneven coloring, etc., to simplify assembly operations and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

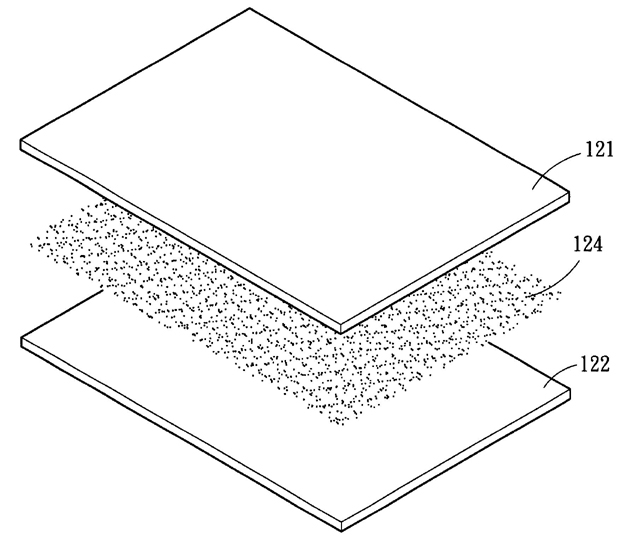

[0020] figure 1 It is an exploded schematic view of the frame light-shielding adhesive film of the present invention. As shown in the figure, the present invention is an outer frame light-shielding adhesive film 1 of a display screen, which can be adhered to a hollow outer frame light-shielding adhesive film 1 around the display screen 2. The outer frame light-shielding adhesive film 1 is formed of a white plastic. The diaphragm 122 and a black diaphragm 121 formed of black plastic are formed by bonding the adhesive 124 to each other.

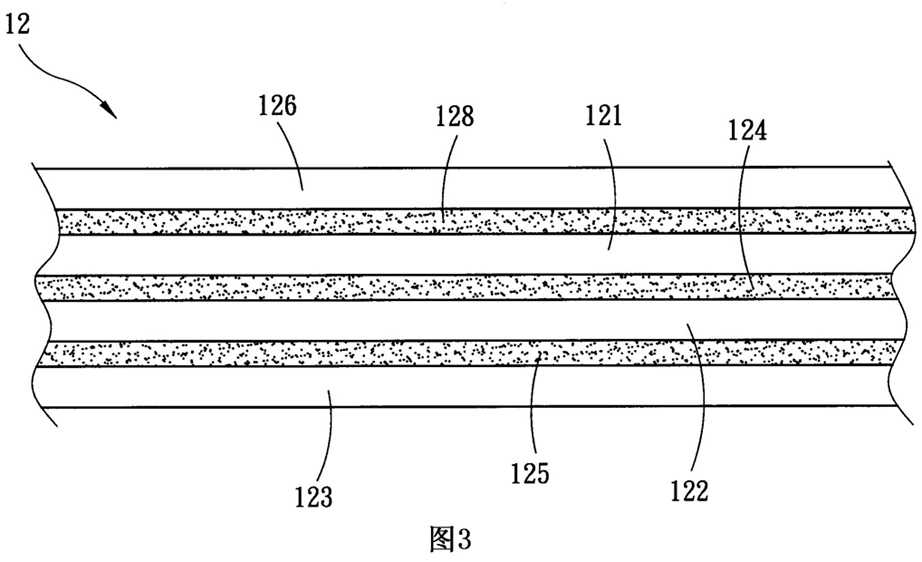

[0021] image 3 It is a schematic cross-sectional view of the light-shielding double-layer adhesive film for the outer frame of the present invention. An adhesive layer 125 is disposed on the other surface of the white film 122 opposite to the black film 121 , and a release paper (film) 123 is covered on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com