Novel axial fatigue tester

A fatigue testing machine, axial technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve problems such as complex structure and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

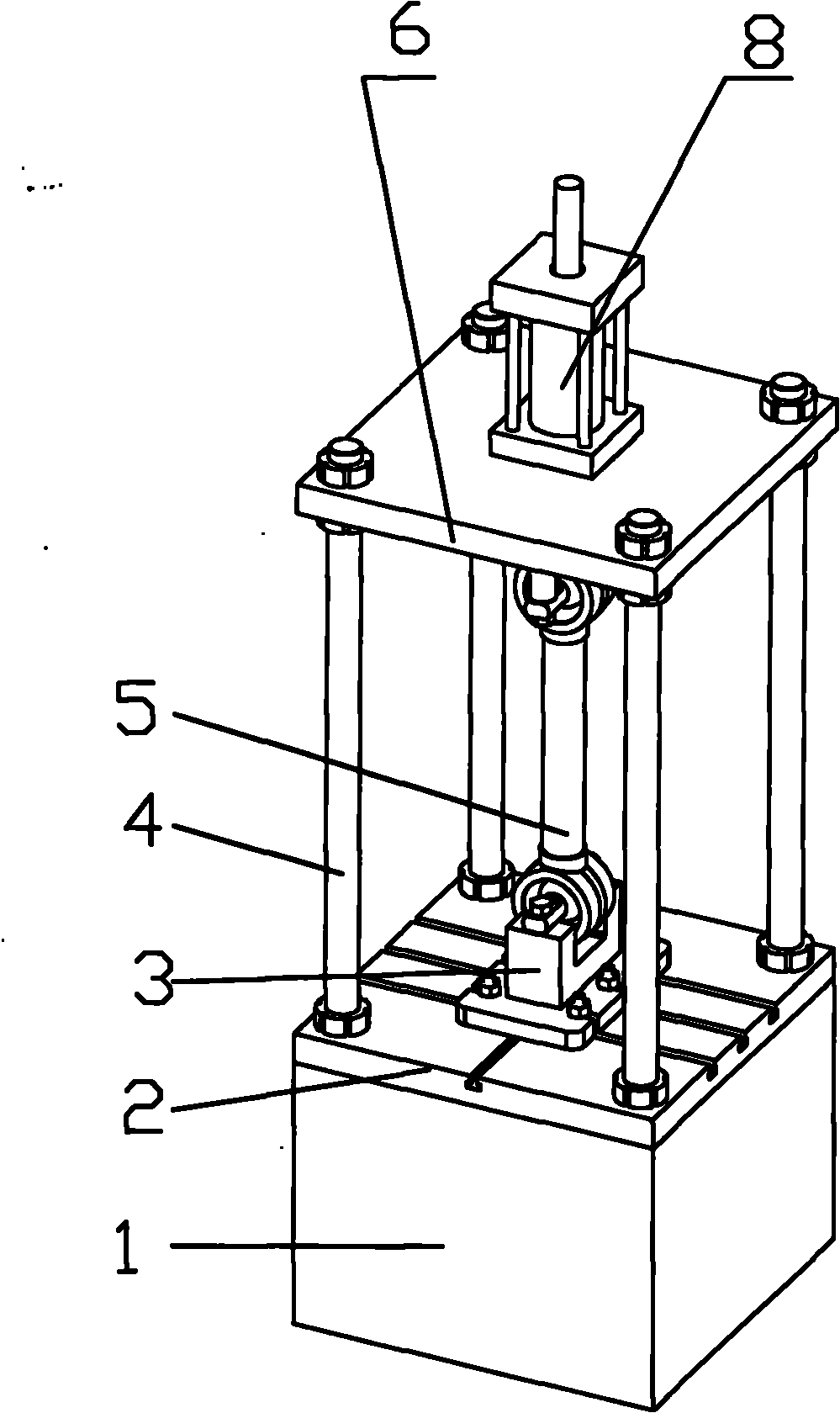

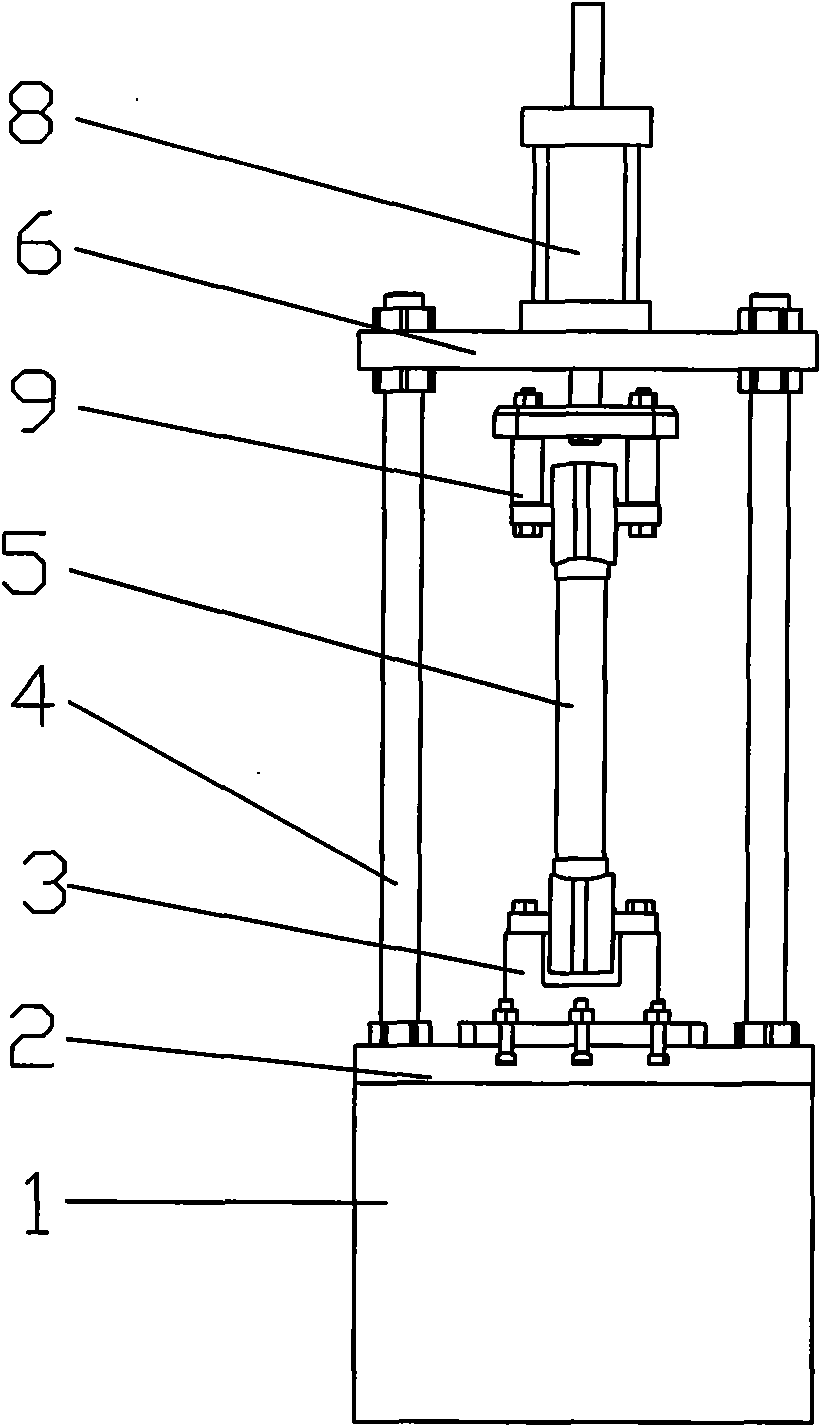

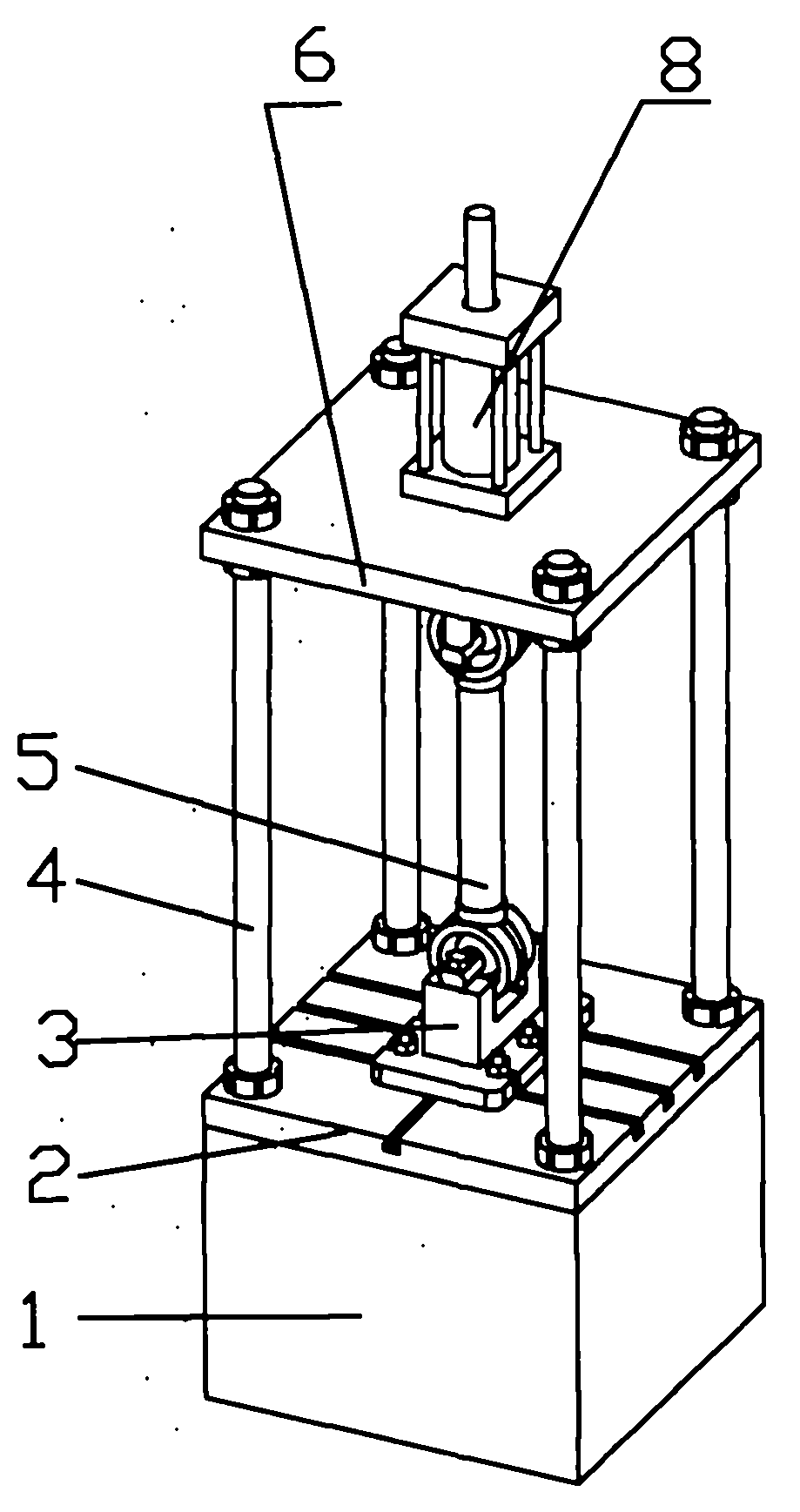

[0010] Such as figure 1 , figure 2 As shown, a new axial fatigue testing machine includes a workbench 2, a lower U-shaped connecting seat 3 arranged in the middle of the workbench 2, an upper connecting plate 6 arranged above the workbench 2, and an upper connecting plate 6 arranged between the workbench 1 and the upper The support column 4 between the connecting plates 6, the upper U-shaped connecting seat 9 located in the middle of the lower end surface of the upper connecting plate 6, the main oil cylinder 8 located on the upper end surface of the upper connecting plate 6, the piston rod lower end of the main oil cylinder 8 and the Upper U-shaped connecting seat 9 is connected into one. The workbench 2 is fixed on the base 1, the support columns 4 are provided with four, and are arranged at the four corners of the upper connecting plate 6, and the lower U-shaped connecting seat 3 and the upper U-shaped connecting seat 9 are installed with Thrust rod part 5. During the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com