Early warning stop valve

A shut-off valve and valve stem technology, applied in the field of shut-off valves, can solve the problems of high maintenance frequency, troublesome and dangerous timely maintenance and replacement of shut-off valves, inability to make timely alarms, etc., and achieve the effect of extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through the accompanying drawings and preferred embodiments.

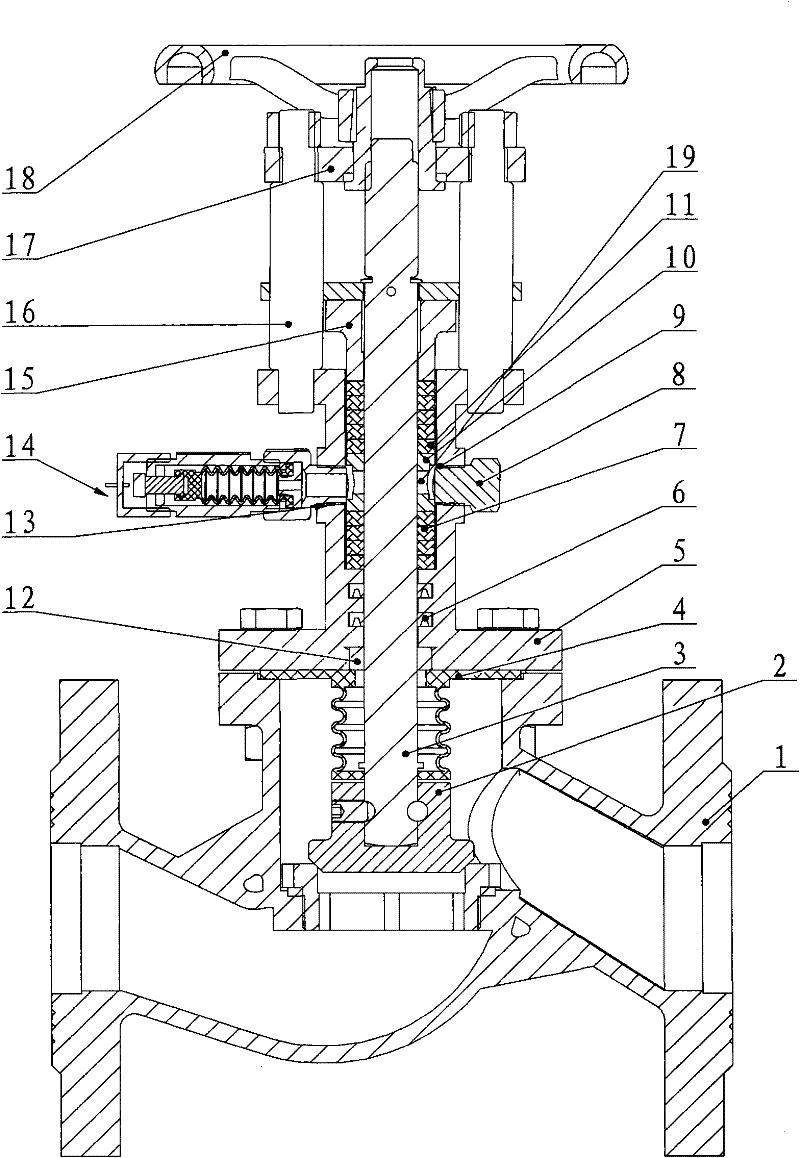

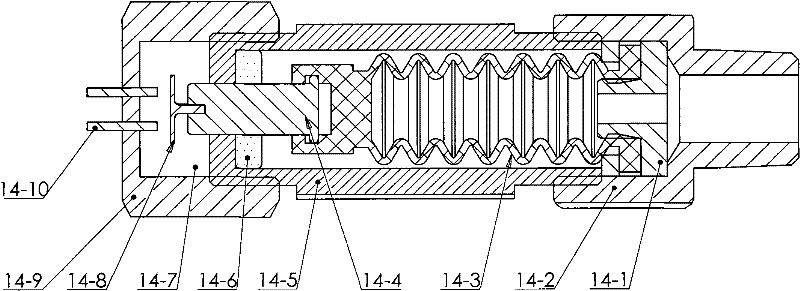

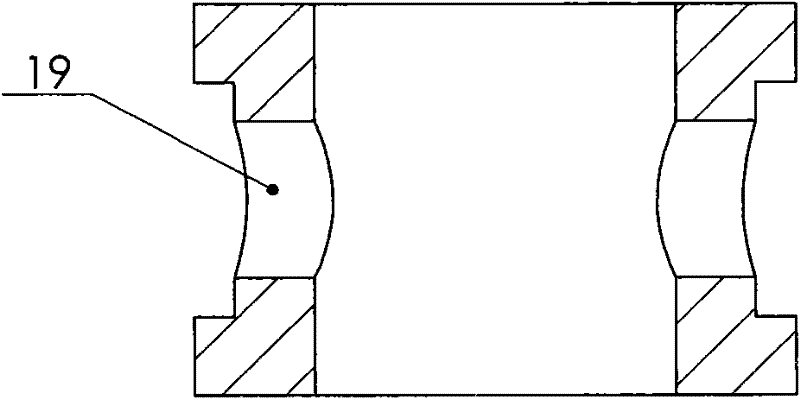

[0022] See figure 1 The valve body 1 of the shut-off valve is provided with a medium inlet and an outlet, and the disc 2 inside the valve body 1 is fixedly connected with the valve stem 3 and sealed with the valve seat of the valve body 1 to realize the throttling of the medium. The sealing bellows 4 inside the valve body 1 and the valve stem 3 are sealed to prevent the medium from contacting the valve stem 3. It can be used in occasions that require strict sealing of the valve stem 3, so that there is no leakage and no fluid at the valve stem 3 Loss, reduce energy loss, improve plant equipment safety; can effectively extend the service life of the valve stem 3, not only improve the use of energy efficiency, increase the safety of production equipment, reduce maintenance times, and reduce operating costs. The sealing bellows 4 expands and contracts as the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com