Novel quasi-physiological pulsating flow environment arterial blood vessel tissue engineering reactor

A technology for arterial blood vessels and tissue engineering, applied in the fields of cell culture and tissue engineering, which can solve the problems of high motor power and other parameters, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

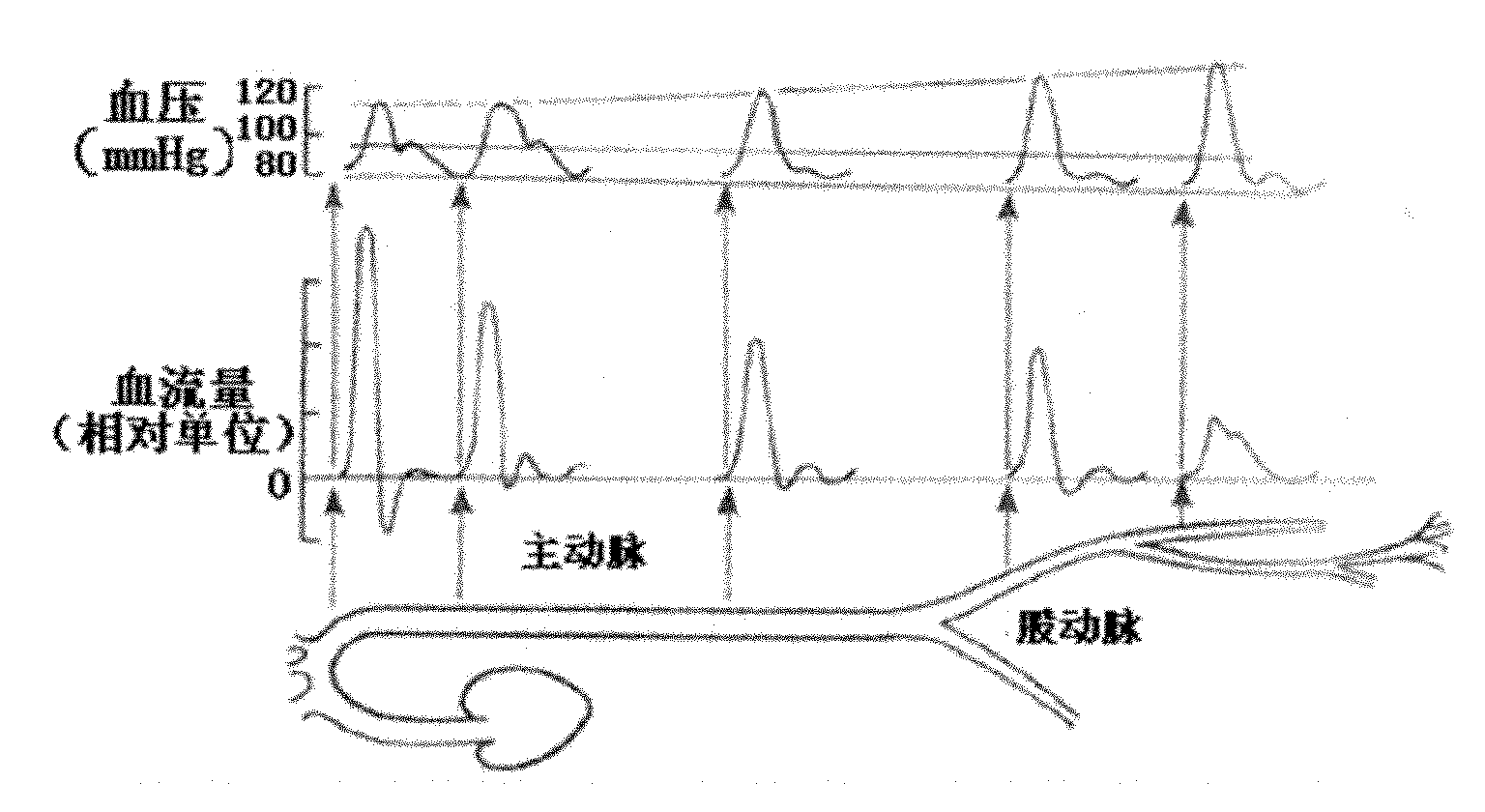

Problems solved by technology

Method used

Image

Examples

Embodiment 1

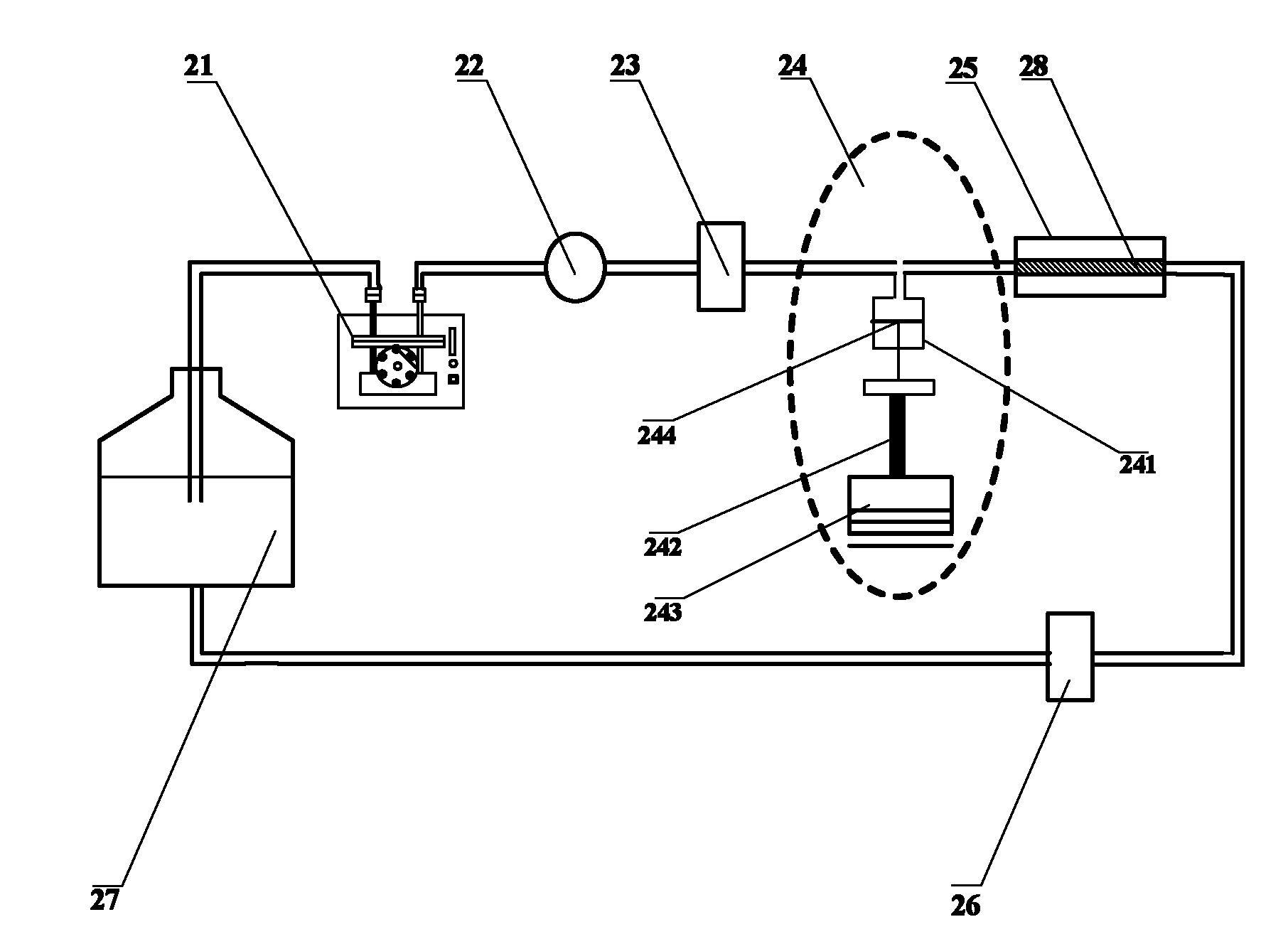

[0068] 1. According to figure 2 Connect the reactor components, including a liquid storage bottle 27, a liquid driver 21, a compliance regulator 22, a first resistance regulator 23, a pulse generator 24, a dynamic culture chamber 25 for vascular tissue, and a second resistance regulator 26;

[0069] 2. Disinfection reactor, disinfection conditions: 130°C, 3 atmospheres, 1 hour;

[0070] 3. Install the tissue engineering vascular culture in the vascular tissue dynamic culture chamber 25;

[0071] 4. Prepare the medium according to the cultivation requirements, and inject the sterile medium into the storage bottle;

[0072] 5. Set the flow rate of the liquid driver, set the motion frequency of the linear stepper motor to 70 times per minute, and set the initial position between the motor gain and 1-5%; start the liquid driver and the linear stepper motor to start perfusion culture;

[0073] 6. Adjust resistance regulators 23, 26 and compliance regulator 22 to control the medi...

Embodiment 2

[0075] 1. According to figure 2 Connect the reactor components, including a liquid storage bottle 27, a liquid driver 21, a compliance regulator 22, a first resistance regulator 23, a pulse generator 24, a dynamic culture chamber 25 for vascular tissue, and a second resistance regulator 26;

[0076] 2. Disinfection reactor, disinfection conditions: 130°C, 3 atmospheres, 1 hour;

[0077] 3. Install tissue engineered vascular cultures in the vascular tissue dynamic culture chamber;

[0078] 4. Prepare the medium according to the cultivation requirements, and inject the sterile medium into the storage bottle;

[0079] 5. Set the flow rate of the liquid driver 21, set the motion frequency of the linear stepper motor to 70 times / min, and set the initial position between the motor gain 1-5%; start the liquid driver and the linear stepper motor, and start perfusion culture ;

[0080] 6. Adjust the resistance regulators 23, 26 and compliance regulators to control the pressure and fl...

Embodiment 3

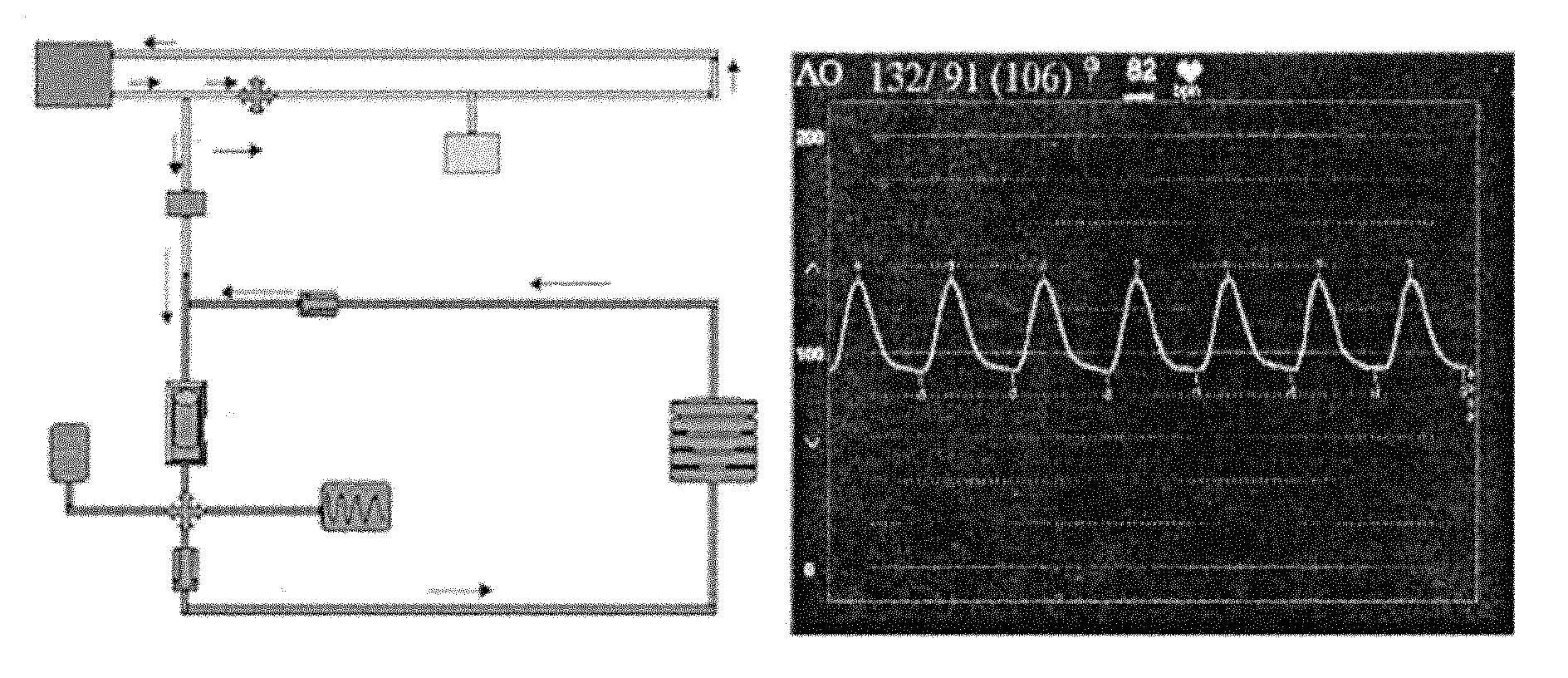

[0083] 1. According to Figure 5 Connect the reactor components, including a liquid storage bottle 57, a liquid driver 51, a compliance regulator 52, a first resistance regulator 53, a pulse generator 54, a heart valve test cavity 55, and a second resistance regulator 56;

[0084] 2. Install the heart valve 58 to be tested in the heart valve experiment chamber;

[0085] 3. Fill the buffer into the storage bottle;

[0086] 4. Set the flow rate of the liquid driver 21, set the motion frequency of the linear stepper motor to 70 times per minute, and set the motor gain between 1-5%, set the initial position; start the liquid driver and the linear stepper motor, and start the perfusion test ;

[0087] 5. Adjust the resistance regulators 53, 56 and compliance regulators to control the pressure and flow waveforms flowing through the heart valve test cavity 55: the inlet pressure is between 110-140mmHg, and the outlet pressure is between 85-110mmHg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com