Preparation method of porous carbon material for supercapacitor

A supercapacitor and porous carbon technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low specific capacitance and large impact of Cl2 environment, and achieve the effect of high and medium porosity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

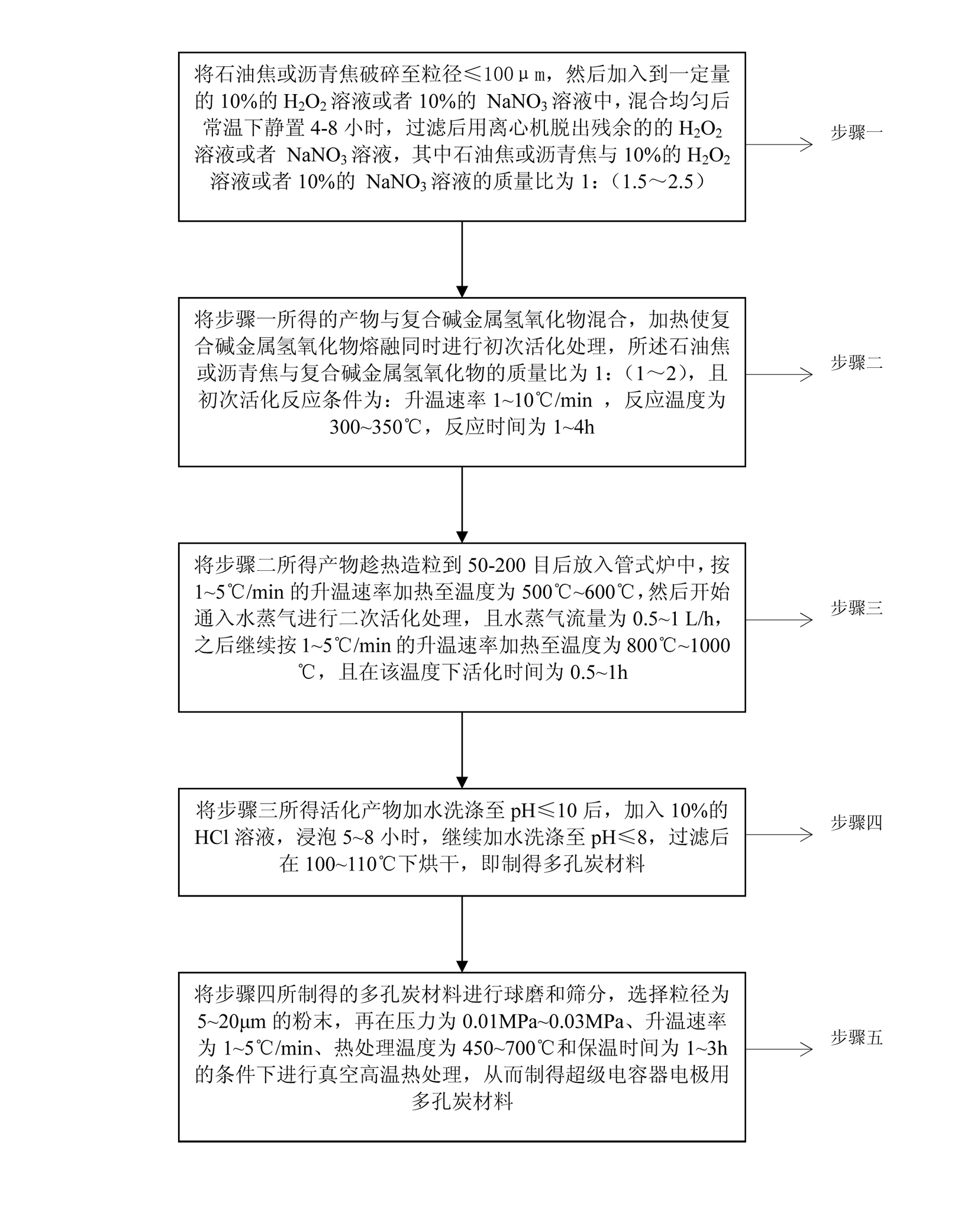

Method used

Image

Examples

Embodiment 1

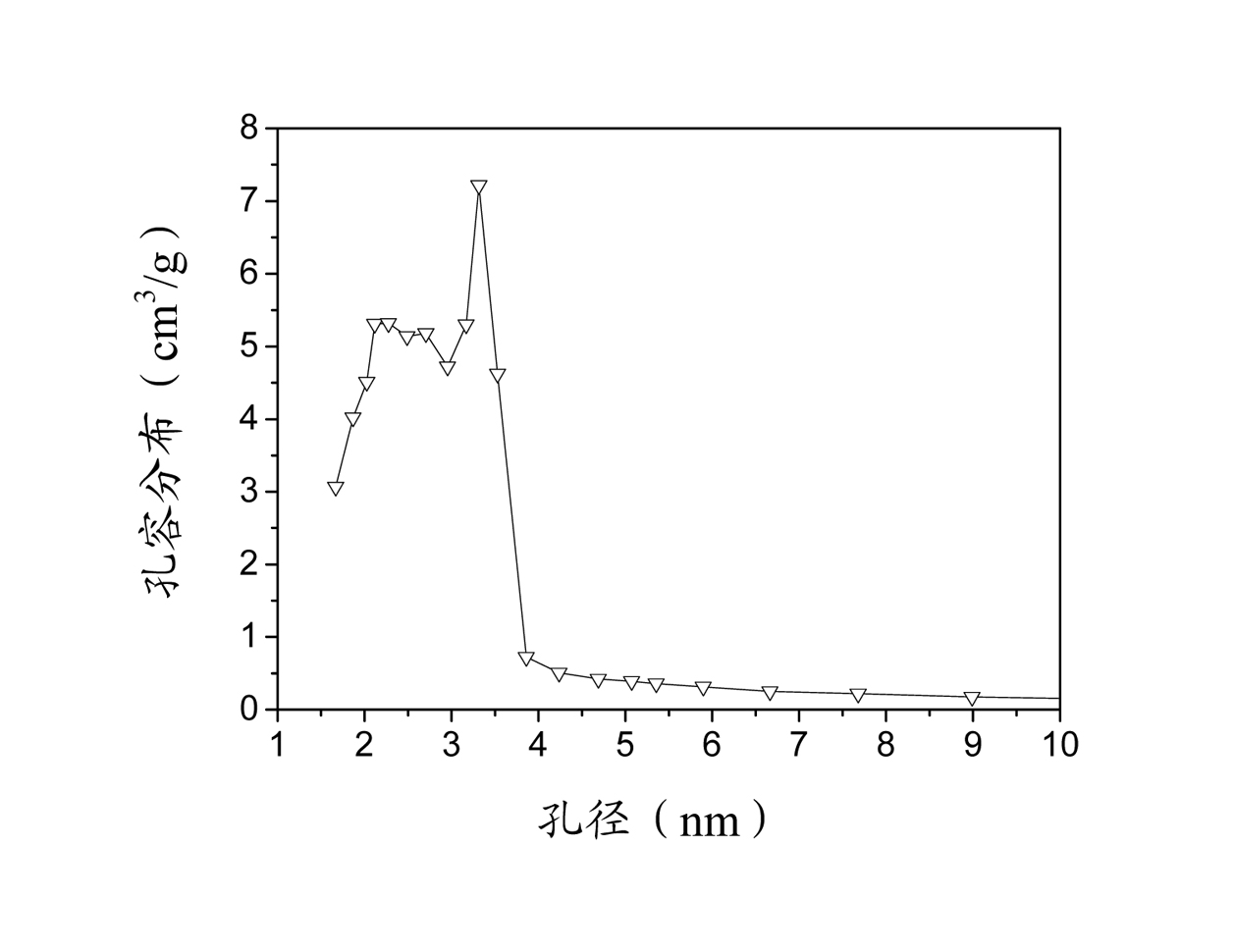

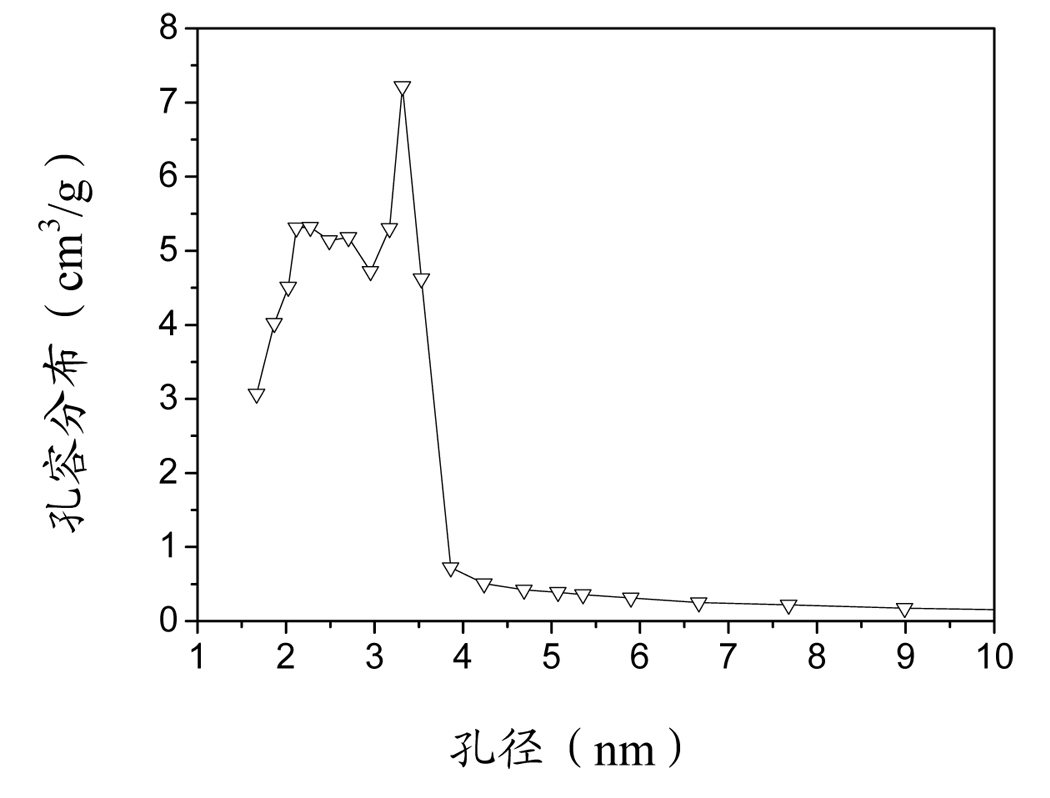

[0028] Take 100 g of petroleum coke, add it to 2000ml of 10% H2O2 solution, mix well and soak for 4 hours, filter and use a centrifuge to remove the residual H2O2 solution. Mix the above-mentioned oxidized petroleum coke raw material with 150g of a mixture of KOH and Ca(OH)2 with a mass ratio of 2:1.5, slowly heat to 300~350°C at a heating rate of 2°C / min, and stir for 2 hours. After granulation, put it into a tube furnace, heat it up to a temperature of 500°C at a heating rate of 2°C / min, and start to pass in water vapor for secondary activation treatment, and the flow rate of water vapor is 0.5 L / h. Continue heating at a heating rate of 2°C / min to a temperature of 800°C, and activate at this temperature for 1 hour. After the activated product is cooled, add water to wash repeatedly to pH ≤ 10, add 10% HCl solution to soak for 5 hours, continue to add water to wash to pH ≤ 8, filter and dry at 100-110 ° C to obtain the prepared porous carbon material.

[0029] The above-men...

Embodiment 2

[0032]Take 100 g of petroleum coke, add it to 2000ml of 10% NaNO3 solution, mix well and soak for 6 hours, filter and use a centrifuge to remove the residual NaNO3 solution. Mix the above-mentioned oxidized petroleum coke raw material with 150g of a mixture of KOH and Ca(OH)2 with a mass ratio of 2:1.5, slowly heat to 350°C at a heating rate of 2°C / min, and stir for 2 hours. After granulation, put it into a tube furnace, heat it up to a temperature of 600°C at a heating rate of 2°C / min, and start to pass in water vapor for secondary activation treatment. The flow rate of water vapor is 0.5 L / h. Continue heating at a heating rate of 2°C / min to a temperature of 800°C, and activate at this temperature for 1 hour. After the activated product is cooled, add water to wash repeatedly to pH ≤ 10, add 10% HCl solution to soak for 5 hours, continue to add water to wash to pH ≤ 8, filter and dry at 100-110 ° C to obtain the prepared porous carbon material.

[0033] The above-mentioned p...

Embodiment 3

[0036] Take 100 g of pitch coke, add it to 1500ml of 10% H2O2 solution, mix well and soak for 5 hours, filter and use a centrifuge to remove the residual H2O2 solution. The above-mentioned oxidized petroleum coke raw material was mixed with 200g of a mixture of NaOH and Ca(OH)2 with a mass ratio of 2:1, slowly heated to 350°C at a heating rate of 2°C / min, and stirred for 3 hours. After granulation, put it into a tube furnace, heat it up to 600°C at a heating rate of 2°C / min, and start to pass in water vapor for secondary activation treatment with a flow rate of 0.8 L / h. Continue heating at a heating rate of 2°C / min to a temperature of 900°C, and activate at this temperature for 1.5h. After the activated product is cooled, add water to wash repeatedly to pH ≤ 10, add 10% HCl solution to soak for 5 hours, continue to add water to wash to pH ≤ 8, filter and dry at 100-110 ° C to obtain the prepared porous carbon material.

[0037] The above-mentioned porous carbon material was f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com