Non-rotating extensible variable sprayer

A telescopic, non-rotating technology, applied to spray devices, spray devices, etc., can solve the problems of high energy consumption, the inability of a single nozzle to complete spraying with any shape and variable, and the operation is not stable enough to achieve low energy consumption, simple structure, and easy operation. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

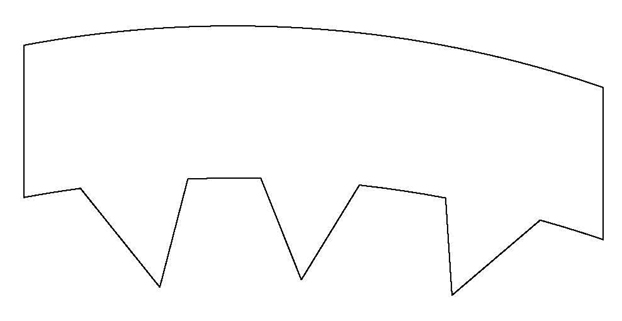

[0021] Such as figure 1 , 5 As shown, the present invention includes a shell connection seat 1, a spring 2, a spray body 3, a nozzle 4, a limit ring 5, a cover plate 6, a rubber ring 7 and the like. The shell connection seat 1 and the spray body 3 are connected by a spring 2, and more than 2 nozzles 4 are arranged on the circumference of the spray body 3, and the number of rows of nozzles 4 arranged on the spray body 2 is 2 to 1 times the number of nozzles 4 , the specific number of nozzles 4 is set according to the actual terrain needs, each nozzle 4 is provided with a limit ring 5, and a cover plate 6 is provided above the spray body 3, and the position of the limit ring 5 can be adjusted by loading and unloading the cover plate 6, The limit ring 5 adjusts the size of the outlet of the nozzle 4 to adjust its shooting range, and the rubber ring 7 is arranged on the inner side of the shell connection seat 1 to prevent the sprinkler from leaking when it is working. The non-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com