Horizontal sand mill

A horizontal sand mill and machine base technology, applied in grain processing and other directions, can solve the problems of easy drying of materials, many wearing parts, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

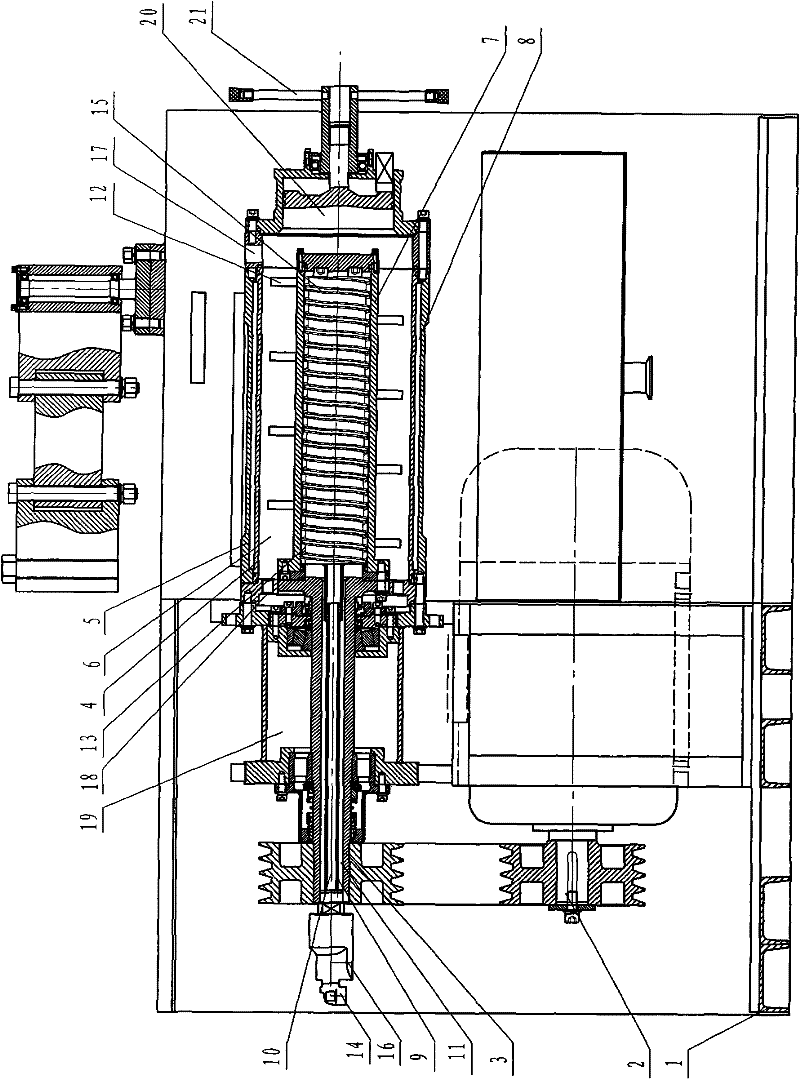

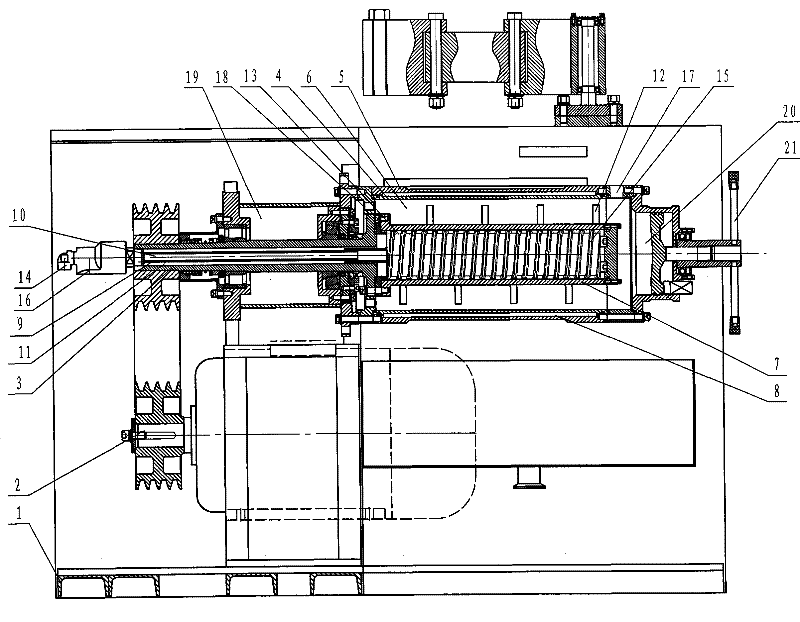

[0010] Depend on figure 1 It can be seen that a horizontal sand mill in this embodiment includes a feeding pump, a base 1, a motor 2 fixed on the base 1, a main shaft 3 connected to the motor 2 through a pulley, and a grinding cylinder 4. In the example, the feeding pump adopts a gear pump or a pneumatic diaphragm pump, and the amount of feeding can be adjusted by the feeding pump. The grinding cylinder 4 is connected to the main shaft 3 through a bearing, and a sealing ring is provided at the bearing connection. The grinding cylinder 4 is composed of a grinding outer sleeve 5, a grinding middle sleeve 6 and a grinding inner sleeve 7. The grinding inner sleeve 7 is fixed in the grinding center In the cavity of the cover 6, a cooling water channel 8 is formed between the grinding outer cover 5 and the grinding middle cover 6. The two ends of the grinding cover 5 are fixedly connected with the two ends of the grinding middle cover 6. There is an intermediate shaft 9, which is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com